Wall Facing Technology Brick Walls

Brick is one of the most sought-after materials in construction. Today, a wide variety of objects are erected with its use. But the use of brick is not limited to the construction of the walls of the building, since the trend of facing by brick masonry is becoming increasingly popular. Such an outdoor finish will improve the performance of the house, will prolong its service life and significantly increase the aesthetic attractiveness of the construction.

Content

The advantages of bricks as a facing material

The process of wall cladding brick has a number of fundamental advantages that determine the choice of this material. Consider them in more detail:

- Brick protects the walls from the negative effects of the atmospheric environment and temperature differences.

- The design of the walls through this material creates a more attractive appearance of the building and insulates it.

- As a result of facing of outer walls, the temperature regime of the room is improved by brick.

- The service life of the task with decoration in the form of masonry will significantly last. Such a house will serve approximately 50 years longer than standard buildings.

Characteristics of bricks for cladding

- There are many types of facing bricks. This material has such qualities as resistance to low temperatures, strength, resistance to various damage to mechanical nature.

- In addition, the cladding of walls under the brick is characterized by a variety of colors, which makes it possible to create an original facade for every taste.

- Today you can find a brick of a wide variety of forms. It can be both rectangular, single, rounded materials and double or one-time.

- The surface of the material can be textured or smooth, and the colors vary from red, brown and yellow to white shade. Different types of raw materials differ in density and porosity, due to which the lining of walls bricks may be the most diverse.

The color of this material is achieved by certain proportions of the clay mixture, various chemical additives and the applied firing mode in the manufacture. Red brick obtained due to the presence in its composition of iron oxides. The higher the temperature is used in the firing process, the stronger the result is color. The facing material of white or yellow colors is manufactured by adding lime to clay. But such a brick absorbs water more, which reduces its service life. Brown material is obtained due to the addition of manganese.

Application area

With the help of bricks, you can make wall cladding from any material. But at the same time it should be noted that the base should be durable and reliable, because as a result of the facing, another wall is actually formed. Consider some features of the application of such a finish:

- The most successful option will be decorating during the construction period. If the facing by the brick of the aerated concrete wall is performed after the end of construction, it is necessary to retreat from the outer edge of the foundation for about 30 cm.

- It should be provided in advance in the main wall installation of binding fittings.

- Separately attention requires facing of wooden houses. It is necessary to create conditions so that the walls of the tree can get rid of excess moisture. To do this, it is necessary to completely remove the waterproofing and vapor barrier layer from a wall cake.

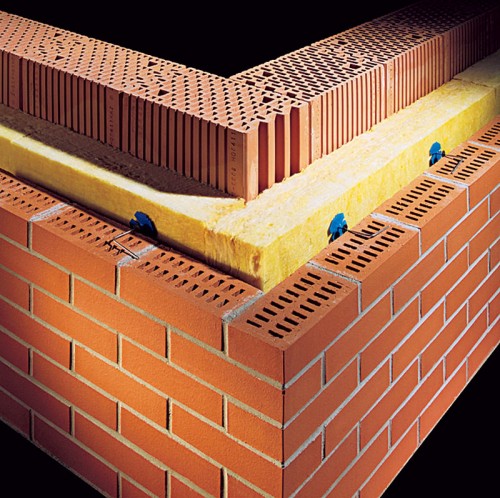

- The use of the insulation is allowed, but at the same time it is necessary to leave the air layer in several centimeters. If this condition is not fulfilled under the influence of moisture, wooden material will be subject to the rotation process.

- The appearance of the facade can significantly spoil the appearance of heights. To avoid such a phenomenon, with brickwork, a solution of thick consistency should be applied. And during the period of work, you need to ensure that the composition does not fall on the outdoor side. Also perform work follows with dry weather, and during the rain, the masonry must be stolen.

Wall Facing Technology Brick

In the case of use for cladding various stones and bricks, the masonry is performed in three ways.

First method Apply in case of finishing by the facial stone. Its sequence is as follows:

- Works should be started with an outer series, on which the facing material is placed.

- After you need to form two inner rows.

- A row of facing bricks is tied with a wall masonry by a toncho method.

- Thus, cladding stones will have a similar height with two rows of masonry walls and will enter half of its length.

- The inner part of the wall and cladding are performed according to the chain dressing system.

Second option Performance of work implies a finishing of facial bricks with the priority lays down the facing versts. The process is as follows:

- For laying the first row, the whole bricks are used, which are stacked by the pump.

- The formation of the following three series occurs in solid bricks, which are stacked by a spoon or a ton of halves of the material.

- Next, on the chain dressing system on the inside of the wall, you must lay out two rows of bricks.

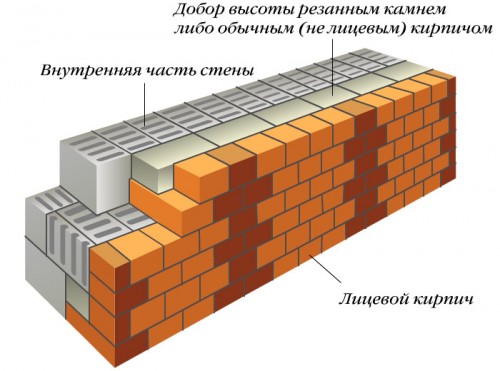

- Then it is necessary to align the height of the masonry above the next to the tilenode. We do it with the help of ordinary bricks or masonry stones cut by the grinder.

- After the formation of every three rows of cladding, the wedge must be tied with a stone wall with the help of tile bricks.

- In the process of cladding, use the dressing system into several rows.

Third option It provides for registration from ordinary brick, which is thickened with a facing material. The process of finishing occurs in the following sequence:

- First of all, using facing brick, you should post an outdoor mile.

- One row must be made by the method of the tick, and three - a spoon.

- On the inner part of the wall lay out the usual brick in four rows along the tacot dressing row of the facing material.

- Further finish occurs according to a similar principle.

Final work

At the last stage, the facing should provide a number of such sublications:

- so that the seams had a more attractive look and became more dense, the solution should be smoothed using a special form for this;

- at the end of the work, the masonry must be treated with chlorine acid. This composition will make it possible to clean the surface of the lining from dust, residual solutions and saws, but this will somewhat affect the cost of wall cladding brick;

- in order for the entire surface of the masonry to have a smooth tone, the facing must be wiped with acidic composition. It follows at the moment when the masonry dried itself, and the solution has not yet managed to harden;

- to give a more aesthetic type of seams, you can fly. To do this, it is necessary to scroll the solution about 2 cm and fill the gap with a dense composition.

Recommendations for the process

- Decide on the choice of facing method, you can perform a specific action. It is necessary to fold two equal stacks of bricks, one of which will be made of facing material, the other of the bricks provided for the inside of the wall. Then the number of units of the material should be calculated. The number of bricks in the facing stack will help to understand how many rows of masonry must be performed in length, that is, a spoon.

- In the design of the series, performed by the spoon, can be brought to a variety, putting several halves instead of a whole brick instead. Thus, it is possible to replace part of the material, and you can and the whole range. Bricks stuck with a spoon will have a type of tiley. Next to spoonful rows on top and bottom should be performed with a tonch. So brick, laid on the wall, will be bonded with the inside of the masonry.

- In the process of cladding, as it has a certain weight, the additional basement or foundation is required. Recommended amount of material for 1 m 2 It is 50 units. Performing the markup of the foundation, it is necessary to provide what thickness will be a layer of cladding, as well as the distance of the retreat from the wall and the base. As a rule, the thickness of the facing layer is 12 cm, while the distance to the wall is 2 cm.

- Since the brick does not pass the water, its content in solution for masonry should be minimal. For operation, a solution of complex type is used - 1: 2: 9, where one part is cement, two falls on limestone dough and nine - on the sand. For fastening the facing layer to the wall, nails are used for 15 cm. Between the facing and the wall you need to leave the space 3-4 cm wide.

- By purchasing a brick for facing, it should be taken into account that the material in various parties made at different times may have a different shade. Therefore, it is recommended to acquire the required amount of material at the same time.

- Transportation, loading and unloading of bricks must be performed in compliance with certain requirements. The material should be packaged in packets and put on pallets, which should then be lifted using a crane and loader. Special accuracy must be shown when unloading bricks. It is unacceptable to drop material from the body. For storage, it is also advisable to use pallets, while they cannot be put on each other. The execution of these recommendations will contribute to the safety of the quality of the material and its appearance.

Conclusion

With the help of bricks, you can perform a high-quality exterior finish of the house, so that the building will acquire such characteristics as durability, as well as resistance to mechanical damage and the negative effect of high and low temperatures. As a result, the service life will last for several decades. In addition, the appearance of the building will significantly improve. Today, the market offers a large selection of forms and colors of facing bricks, which will provide the opportunity to embody a wide variety of design solutions.

The rules of wall cladding brick on video are shown below:

New comments

Add a comment

To send a comment you need authorize.

A very useful article in my opinion, I also chose a facing brick for a long time, eventually chose Avangard firms, it turned out to be qualitative.