How to choose manual tile Instruments

Did you decide to put a tile? You will certainly need a tile cargo. But before buying it, you should learn more about its features and nuances to make it easier to choose. The accuracy and quality of upcoming work depends on the selected tool. If you do not know little or almost anything about the handling tile, then you need to know how to choose it.

Content

What is slabcores

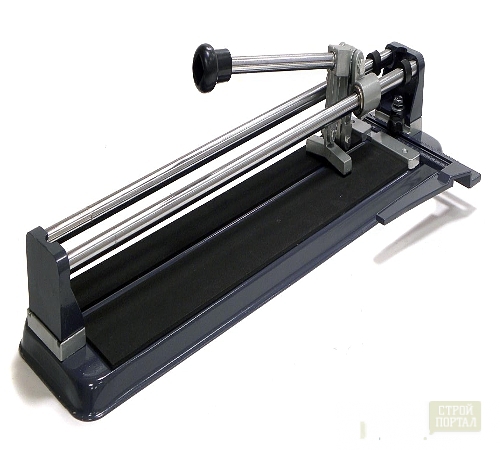

So, the manual stoveture is a simple mechanical tool (acts with the help of human hand) for cutting different types of tiles. The main part of its design is a cutter, which conducts on the front side of the tile, and gently knocking on it, the tile is blocked along the cut line.

It is easy to handle it and conveniently work without dust and noise. But choosing a manual stovetur, think why you need it: for rare, home use and for long, frequent professional use. Pay attention to the tile thickness with which you work, that is, to the depth and length of the cut.

Choosing a slab in the store, do not look at the price, and on its characteristics and quality. If it is needed for long-term use, then buy a high-quality professional tool.

Properties of high-quality manual slab

When choosing tool, pay attention to:

- The strength of the frame is that it does not quickly fail, it should have a thick, durable, hard frame. Check the handle and lever. It should have a strong handle and a powerful lever. This is very important, especially if you cut fear stonewares.

- Tool length. Since the length of the tile cut can vary from 100 to 750 mm, respectively, the tiles should have this length. Do not save, buying short plates. Better overpay and buy a universal tool. With it, you can easily achieve the depth of the tile cutting from 3 to 30 mm, for walls and for the floor, or when you need to cut diagonally. Of course, you can break the tile using the grinder, but it is very dusty and noisy.

- Smooth stroke. In fact, all the strong plates have in their device bearings that contribute to the smooth slide of the cutter during operation. Before buying, will certainly test the tiles. Cut multiple tiles to make sure that the mechanism runs smoothly and clearly, and the tile is blocked strictly along the cut line.

- The base should be attached to the desktop and not slide.

- It is desirable that it was equipped with a tilter, and allowed to strengthen the tile at any angle in the direction of the cutting roller movement.

Technical characteristics of manual slab

The basic part of each tile cutter is a cutting roller made of solid fused steel. The cutting quality becomes worse as the roller is blown off. It cannot be sharpened as an ordinary knife, but only replace. A more expensive tool is equipped with a roller with a diamond coating. It is more durable and allows you to do a long-term res.

There are also plates having a swivel line with which, you can make a cut under the necessary angle. High-quality plates of different well-known firms manufacturers have all sorts of options:

- mOCELLATE MATERIALLY MODE,

- restrictions on the movement of the rolling paws,

- preventing edge crumbling.

One disadvantage of almost all stovetures is the fact that they do not cut off about 4-5 mm from the edges of the tile. And then you have to use special nippers or a grinder.

Platekores are three types:

- which make an incision, and the master cleans the tile by hands;

- fully cut the material;

- blinking small pieces from the edge.

And:

- nippers, with which, you can make curly cuts in the tile up to 8 mm;

- separately cutting roller for performing direct or curly cuts up to 15 mm.

- the electric stoveture allows you to interture to the exact parts of the tile with a thickness of up to 40 mm.

Summing up a small result, we can say that for laying the houses of the house in the kitchen or in the bathroom you will be suitable for hand tiles mechanical for cuts up to 15 mm, and if you are going to work professionally, then you will need an electric stovetur for cuts with a depth of up to 40 mm.

And one more advice: before deciding which manual tiles to buy, view all the available photos and videos on the Internet about the possibilities and methods of work of each type of existing tiles.

Overview of high-quality tiles manufacturers

You will find on sale different brands of tile cutting devices, but the most high-quality products of the following manufacturers:

- Basik Plus,

- Bison

- Matrix,

- Monolit,

- SIGMA

- Stayer

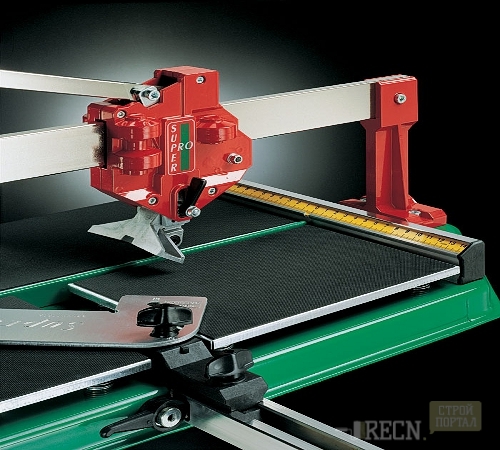

- Supper Pro Battipav,

- Raimondi,

- Ruby.

The Basik Plus manual tiles has an aluminum bed, which cuts the tile and two nickel-plated guides of high rigidity, with a handle. They are covered with chrome, and therefore reduce friction. The tool carriage is made of polymer and therefore, it is not necessary to lubricate and clean it. A long handle will allow you to spend less effort while working.

Handmade Matrix Sticker (Matrix)

Matrix manufactures professional building equipment. And judging by the reviews, its hand-made railclosure, Matrix 600 and 500 mm models, most popular among all components available on the construction market. It is equipped with a single rail of steel alloy, bearings and handle. Stability during operation is achieved using special bolts that regulate clamping girth.

Manual Rubbie

Hand-made tiles from the German manufacturer Boada (1951), Rubi TM-70 is also very popular among semi-professional and professionals. Suitable for working with ceramic tiles, and even with extrusion porcelain. Adjustable for the depth of the cut from 6 to 21 mm using a murge separator.

His guides are made of chrome steel. He has a side limiter, which allows you to repeated cutting under 90 0 and 45. 0. This model is more popular than others available in the assortment of Rubi tiles.

Manual Sigma Platekores

SIGMA provides its consumers in Europe and the CIS, a wide range of construction tools since 1994.

Powerful plates, which can cope with thick, embossed tiles, having a separating power of 1150 kg. All Sigma tiles are distinguished by the fact that the handle is separator on the bearings and the amortization effect. This allows the tool to work smoothly and smoothly, but with high power, and achieve an excellent result. Convenient for use is the wing base, which is made of galvanized steel. As well as a system of clear fixation, which allows you to cut at any angle.

Manual stove monolith

In the assortment of Montolit, there is a group of plug-breeding series, made to cut the tile and stone of all sizes and hardness. This rigid device has auxiliary options for adjusting the paws and setting the cut thickness to 25 mm.

Manual Stayer Platekores

Since 1999, the Staer trademark, the German company KRAFTOOL, is popular in the construction markets of Europe and Russia. Everyone knows German accuracy in all details, ergonomics and high quality. All this is equipped with Hand Toles Stayer.

The most popular model is Stayer 3310-60 slab. This type of slab cutting contains a circular cutter that allows you to make circular cuts D 30-80 mm on a ceramic tile up to 15 mm, and also equipped with a ruler and a coal for dissection under 45 0 and 90. 0.

Trying to answer the question of the cost of manual stoveturis, it is impossible to give unequivocal information, since the price depends on many factors. But the price range varies from 266 to 17000 p.

We told you about various models of plates, but the choice remains yours.