Build a garage with your own hands Construction,Plot.

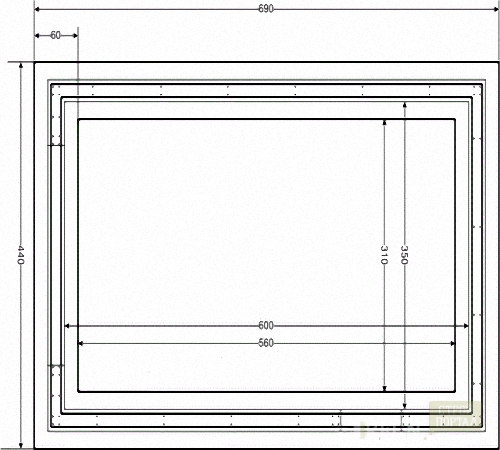

In order to build a garage with your own hands it is difficult, it is necessary to approach the construction responsibly, stock patience and necessary inventory. To begin with, an exemplary diagram of the finished garage is drawn. It reflects all the dimensions of the specified building. The most acceptable dimensions for the garage are - 6 meters long, 4 meters width, and a height of about 2.5 meters.

Content

Preparatory stage

Prepared the necessary tool:

- roulette,

- angular line (for checking direct angles),

- level,

- hammer,

- self-tapping screw

- shovel, welding machine.

What is the construction begins? Of course, from the foundation. And it is better to choose a monolithic foundation under the garage, as it is able to withstand permanent loads at arrival or car departure. And also, the monolithic plate will serve as a finished floor in the garage. Getting to work:

- select the site and to extinate the length and width of the garage, pegs are driven into the corners,

- across the area to dig a hole with a depth of about 0.3 m, if the soil blends greatly, then 1 m,

- dno covered with a thin layer of rubble - this is a drainage, he will miss an excess moisture from the solution, while the concrete will not give a shrinkage,

- on the perimeter of the site, the formwork is built, which from the inside is lined with a polyethylene or rubberoid for tightness,

- rugged care is reinforced by a special lattice of reinforcement reinforcement 14th,

- the pit is poured by concrete solution above the level of the reinforcement by about 6-10 cm.

After 10-15 days the foundation hardens, it will become durable - go to the construction of the walls and roof of the future garage.

Choosing a building material

The garage should be not only a reliable home for the car, but also to respond to the temperature requirements. And if inside it will be too wet - the metal of the car is waiting for fast corrosion. Therefore, the temperature should be approximately + 5-10 degrees Celsius, and humidity is about 50-70%. And in order to achieve these parameters, you need to choose correctly, from which material to build a garage.

Wooden garage can be built, but not recommended. Since it does not fully meet all fire safety indicators. In addition, it will be necessary to additionally install the heating system of the room.

Another option is a metal garage, but due to the temperature difference there is a humidity there, and the car begins simply rust, and in the regions with a cold winter (from - 20 degrees Celsius) such a garage will not be warm. Plus, all times a year or two will have to do current repairs (painting).

The most reliable materials are:

- brick,

- ceramzitobeton,

- foam concrete (aerated concrete),

- a natural stone,

- sandwich panels.

Consider each of them in more detail.

Brick garage

Construction of a brick design is one of the most economical and simple ways to arrange a reliable garage.

- First, before proceeding with the construction of the walls, it is recommended to build a base. This is the lower part of the garage wall, which serves as protection against dampness and cold. It is built from ceramic brick about 30-35 cm high.

- Secondly, that the garage is smooth and stable, it is necessary to properly put brickwork. Bricks are strictly horizontally, where the subsequent row is superimposed on the seams of the previous one. Must with the help of a remote corner line are output perfectly direct angles.

- The third stage, the floor is filled with a screed. From the side of the check-in build a breakdown with a width of 50-60 cm. It should have a small bias directed from the garage.

- The fourth is the construction of the roof. Her tilt must be no mee 30 degrees. First collected rafters. They consist of 100 * 100 bars and are attached to the walls on which Mauerlasts are already fixed.

- Bruks are flattened by forming a arch, and fasten with anchors. The insulation and vapor barrier film is stacked on rafters.

- From above, these materials are clogged with boards, on which the facing material is then fixed.

- From the inside, the roof is stone with wooden boards.

- Finally, the fifth, is the gate. The gate should be 2 meters high for passenger, and 2.5 meters for trucks. The width of the gate is calculated by the formula - the width of the machine plus 60cm.

- The first thing is welded a metal frame to the slopes of the walls, then the loop and the gate is installed in them.

Brick garage with their own hands built.

Foam concrete garage (aerated concrete)

The garage of these materials costs much cheaper than bricks. But at the same time they have a large number of positive properties. The walls are perfectly preserved heat, differ in good frost resistance and durability. Build from foam concrete is very easy, so the entire building process takes significantly less time. It happens similarly to the fact that both of the brick. Only masonry solution is used special for foam blocks.

Of the disadvantages, less durability should be allocated. In addition, temperature drops do not affect foam concrete, so it must be insulated and plastering.

Garage of ceramzite concrete blocks

This design will cost cheaper from brick construction. Ceramzit concrete blocks have dimensions of 39 * 19 * 19 cm, and their laying proceeds quickly. In the garage of these bricks there will always be warm and dry, so this material is well resistant to wet weather. Garage is built absolutely according to the same scheme as from brick.

As in the case of foam concrete, an outdoor decoration is necessary. Keramzitoblocks are very susceptible to mechanical damage. The slightest violation of the integrity of the block leads to its complete destruction.

Garage from sandwich panels or frame garage

This is also a worthy material for its technical characteristics. Panels are lightweight, safe, easy to work with them. The surface is covered with a thin steel sheet and polymer paint. Therefore, buildings from nor have a very presentable appearance. The acceptable thickness of the walls of the garage from the panels is 12 cm thick together with the facing.

- For mounting panels used framework. It can be made of metal pipes, metal profile or wooden bars.

- First all over the perimeter fastens the starting bar. He is the basis for which the framework itself will be held.

- After installation, the racks and jumpers are mounted to it, forming the grid around the perimeter.

- For the roof, a diagonal doom is made.

- The frame elements are bonded with each other with screws or for metal or wood.

- Outside the case is covered with panels, the insulation is packed from the inside and is also closed with panels.

- Mounted gates.

Garage of natural stone

Of course, this is an expensive building, so the cost of natural stone is high. Undoubtedly, the garage from this material Budyen is almost eternal. The laying of natural stone requires a certain skill and skills, a special solution is used to work with it. This stone is structural, so it is necessary to lay it, selecting each in shape. Work time-consuming, it is recommended if you really want to use a natural stone, building a base from it. Such an option will give a garage an additional fortress and durability.

Interior decoration garage

If it is a brick garage or built of foam blocks, a ceramzite concrete, the interior decoration is made by plastering and painting walls. Also, the tile laying is allowed. It is necessary to lower the tile on the floor, it is not only convenient from the practical side, but also protects the screed from premature destruction.

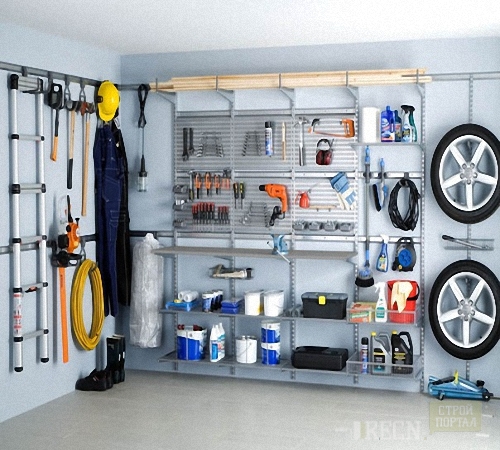

If it is a skeleton garage, then from the inside it is separated by panels. Various small shelves and cabinets for storing tools and other economic equipment weigh on the walls. For saving space on the walls, approximate building hooks are fixed. The main thing is that in the built garage it was comfortable and convenient not only for a car, but also his owner.

New comments

Add a comment

To send a comment you need authorize.

Good afternoon tell me a good channel or video hosting about construction. Very necessary.