How to build a frameless hangar do it yourself Construction

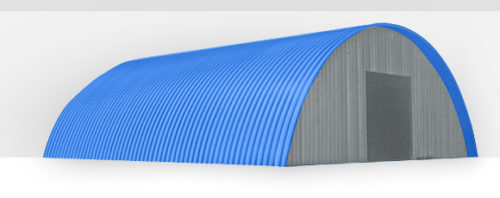

At the stage of choosing a version of the construction of the hangar, the speed of installation, the practicality and mobility of the future room is taken into account. After all, the hangar often has to be disassembled and moved to another place. In this case, the optimal version will be the technology of frameless hangars, thanks to which it is fast and easy to build reliable, durable and practical premises. In addition, the construction of such designs in the cost is much cheaper than the construction of frame structures. Next, we will tell you about what frameless hangars, as well as about their design and construction methodology.

Content

Characteristics and types of angry rooms

Over time, the purpose of the angry rooms has somewhat modified. And if they used to be used exclusively to accommodate aviation equipment and components in them, today they are placed here as various food and non-food products, raw materials, equipment, etc. We can say simple words that the hangar today is used as a storage room for large and small enterprises.

The main characteristic of hangar premises, thanks to which they are popular, their capacity is considered. In addition, the technology of the construction of frameless hangars is quite developed today, due to which, in addition to warehouse space, even sports complexes, outlets, exhibition halls, etc. can be accommodated in the hangar today. Such rooms are used in various areas of our activity - in construction, in production, in Agriculture (for storage of croup and grain), in trade. Given the multifunctionality of the use of hangars, the premises data must have appropriate characteristics and meet the established strength and reliability requirements. In some cases, storage rooms are equipped with windows, gates, ventilation and air conditioning systems. Sometimes the designs are erected so that they can be assembled and understanding at a convenient time.

Today, such premises are erected from metal structures, then if necessary, they are trimmed by any coating. Depending on this, several varieties of such structures are distinguished:

- Cool. Built on ordinary technology from metal products. We usually be truncated. It uses such structures for temporary storage of equipment and goods, as well as to keep equipment here, which does not need insulation.

- Insulated. Early on another technology, rather than the "cold" type. The insulation of the frameless hangar is carried out with the help of a layer of mineral wool, which is stacked between the metal structures. In the future, Minvat is processed by special foam. Such buildings are intended for storing products and equipment, which requires special temperature conditions.

The design of the first and second type can have a different package, depending on the purpose of the room and based on the requirements of the owners. So, hangars can have windows, doors, wickets, stained glass, beams, partitions and other elements. Equipment for frameless hangars similarly can be different. In addition, the premises in itself must meet the safety regulations, as well as be convenient for future use.

Methods for organizing the construction of a frameless hangar

Construction of frameless hangars - the case is very troublesome and not many can cope with it on their own. After all, for this you need to have extensive knowledge and the necessary luggage skills. Those who are going to build frameless arched hangars with their own hands, you can use the recommendations given in this article. However, for the category of people who have all the knowledge of construction, the maximum, to the liner of wallpaper, there is another option to organize construction - the assistance of construction companies.

Specialists usually assist in obtaining the necessary documents, as well as in design and construction. If the project of the future house has already been chosen, then the next step will be the choice of artist. Currently, many construction firms have a fairly narrow specialization of the work performed. So, some of them specialize in land, others - on roofing, and the third - they are engaged exclusively by plumbing. The fact is that special permissions are needed to perform certain works, and many companies are in no hurry to spend money on many licenses, preferring to have one for a profile type of work. The best way out in such a situation will be the general contractual. A company that will produce basic works on your facility will be a general contractor, and those companies we will hire to perform specific work - by subcontractors. As in all matters, the general contractor service has its own positive and negative sides.

What advantages are the general contracting? One of the most important advantages of this type of construction organization is to control the quality of their implementation. The general contractor, who concluded a contract with the developer, is responsible for the construction of a frameless hangar from the pit to finishing works. Taking the work performed at the subcontractor, the general contractor is fully responsible for the result of its work. In the event of any controversial situations, the Customer will solve them only with one company, which will save him from "Pinania" of some performers to others. Another, as a rule, companies with a narrow specialization make their work much better than the "masters for all hands", therefore using the general contractor as a coordinating link, you can achieve a good result.

There is in the use of the services of the general contractor and its minuses. First, this is the cost of construction, which will be higher at least 10%. Secondly, unclean general contractors can overstate the cost of subcontracting works, thereby generalizing their client. But even with these shortcomings, the general contractively remains a fairly effective way to organize the construction of a frameless arched hangar.

Benefits of frameless angry rooms

Frameless hangars have many advantages and are considered more economically more profitable than frameworks. Consider more "Strengths" of frameless angry rooms:

- Easy installation of frameless hangars. In order to build such a design, it does not require high time and money. If you approach the process of the construction of the frameless buildings "WITH CLEAR", then you can build a building for 1-2 months personally, without resorting to the help of construction companies. To build such hangars, the arrangement of a complex foundation is not required. Thanks to this, the design can be disassembled at the required moment and move to another place.

- Strength and reliability. Observing all the rules for building frameless spaces, you can build a hangar, which will serve for more than 25 years. Even considering that such structures are built quite quickly and simply, their reliability has been proven during operation. The construction has persistence to adverse weather conditions, for example, can withstand up to 400 kg of snow dropped in winter. In addition, frameless structures have high fire safety performance.

- Efficiency. Due to the speed and simplicity of installation, such buildings are considered rather economical. It is possible to reduce costs by the absence of a complex foundation, as well as various expensive fasteners, which are mandatory required when the framework of framework buildings is erected.

The order of installation of frameless hangar

Frameless hangar is erected from metal profile. The basis of the structure is the metallic arch. The dimensions of the building are calculated depending on what purpose in the future the construction will be destroyed.

Phased procedure for performing work:

- First of all, the draft frameless hangars is drawn up. It must take into account all the subtleties and nuances of future construction, including the arrangement and cleaning of the area on which the design will be built. At the design stage, the dimensions of the angry room are calculated, the width of the spans, the height of the arch, which is the basis of the structure.

- Schematically indicates where window and doorways will be located, ventilation holes. During the preparation of the plan, it should be determined which materials will be involved in construction. So, the dome is recommended to build from plexiglas or polycarbonate. Thanks to these materials, a sufficient amount of natural sunlight will fall into the premises.

- Laying the foundation. It should be said that for frameless buildings, it does not need a complex basis, so you can build any of the available types of foundation. The parameters of the foundation will depend on the purpose of the construction, which goods or techniques will be inside the warehouse (its weight, dimensions, etc.). Most often for such buildings, a tape or slab base is erected. The trench is pre-pulled out, on the bottom of which the pillow of fine rubble and sand is stacked.

- If the foundation does not need to install the reinforcement frame, then you can immediately go to the fill process. The solution should be thoroughly tumped. Then you need to give time so that the base is frozen.

- Next, the walls of the design are erected. For this, the rolled galvanized steel is most often applied. Given the dimensions of the hangar prescribed in the project, the cutting of steel into pieces is ordered. The next step you will only have to assemble the design, setting the finished parts to the base of metal. For fastening pieces between each other, a wrestling machine is used. Such technology makes it possible to build a room that is characterized by high characteristics of waterproof and fire safety.

- For reliability, you can handle the seams between the design elements using welding. Angar is covered with profile flooring.

- At the request of the owner and, depending on the target orientation of the construction, you can equip heating, ventilation, sewage system, etc. If it is planned to insulate the hangar in the future, then it will take a polyurethane foam or sandwich panel with different fillers.