Jumpers for window and door openings: calculation, manufacturer with your own hands Construction

In the process of building buildings, one of the most complex problems is to install the jumper of the window or door opening. It must comply with all the requirements, to be durable to prevent the walls and deformation of the window frame or the door box. With the seeming simplicity of work, experience and knowledge is needed for mounting jumpers. About how to make a jumper with your own hands in door or window openings - further in the article.

Content

- Performing the calculation of the load of the jumper for window and door openings

- Installation of jumpers with your own hands in brick and block buildings

- Production of jumpers for window and doorways do it yourself in frame houses

- Strengthening the opening of the bearing walls

- How to pour jumpers over windows with your own hands: photo

- Jumpers do it yourself: video

Performing the calculation of the load of the jumper for window and door openings

In construction under the jumper it is understood as the usual concrete beam, which is stacked on the walls and is the basis for the masonry of the next row of bricks or slag block. The design of the opening must meet certain requirements:

- The walls of the walls should normally perceive the load of the support beam.

- The brain deflection (its residual deformation) must correspond to the permissible values \u200b\u200bfor windows or doors that will be installed in the opening.

- If the wall made of brick masonry is maintained entirely, the jumper is temporary. After drying the solution, the melting is capable of maintaining itself, forming a normal opening, so the jumper is no longer performing.

In other situations, the parameters of the beam are calculated using the applied load. This parameter must include:

- The weight of the jumper itself. This is especially true of heavy products from reinforced concrete.

- Wall weight over the opening. At the same time, it is necessary to take into account the self-supporting ability of masonry.

- Wall weight distribution.

- The load, which carries the wall from the support of the jumper beams and the slabs of the overlap.

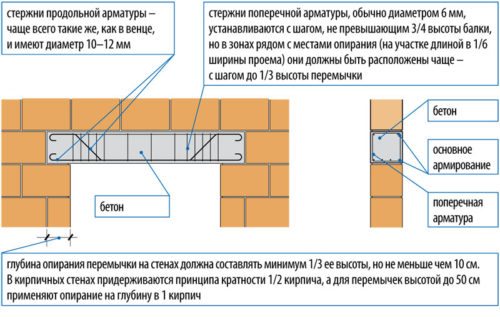

The width of the linear jumper should be equal to the thickness of the wall, and the height is determined depending on the carrying ability of the jumper. The length of the beam, which is used in the overlap of the window opening, depends on the material from which the masonry is made. For brick, the depth of the jumper inside the wall should be at least 100 mm, for the slag block and blocks from other porous materials - at least 300 mm. Multiplying this figure to 2 and adding the width of the doorway, you can calculate the length of the jumper.

It is worth noting that the finished reinforced concrete product is not always used as the window or doorway beams. Quite often the use of wooden bars, or welded metal structures. Sometimes they cast a jumper reinforced concrete "on the place". Over the opening is installed formwork and reinforcing steel design. Then in the formwork poured concrete. This method is notable for the fact that you can make a jumper of the desired dimensions, even on non-standard outlook sizes.

Installation of jumpers with your own hands in brick and block buildings

The easiest solution to the issue of the construction of the jumpers of window and doorways could be the elimination of their dimensions directly under the slab of the overlap. However, this option is simply impossible. The fact is that there should be at least 7-8 rows of bricks or 2-3 rows of blocks between the passing jumper and the beginning of the reinforcing belt.

The simplest task in the installation of the top of the window or door opening is to work with walls that are not supported for overlapping. If the brickwork does not meet the requirements of support, then brick rows are enhanced by reinforcement. Between each brick, which covers the window or doorway, special paper clips are stacked. They are made of wire with a diameter of at least 4 mm. The reinforcement is started under them, which stacked along the masonry. This technique will allow bricks better to stay together.

If the building is erected from foam blocks, the jumper installation over the windows is carried out even easier. It is erected from blocks on a special support. As a support, boards with a thickness of at least 40 mm are used, which are installed supports. After the solution is grabbed, in blocks that are formed by the jumper, the groove is done on top. Its thickness should be at least 300 mm, and the depth is at least 200 mm. The groove is laid in the reinforcing design of the reinforcement with a diameter of 10-12 mm. Then the solution is poured. Recently, manufacturers of building materials offer ready-made U-blocks that have a chapel shape. Working with such blocks is much easier than with usual. After concrete freezes, the blocks will serve as a monolithic design.

Another way to install jumpers on the window or door opening is the casting of concrete jumpers with their own hands. Unlike the mounting of the gutter from blocks, the formwork is installed removable. She rests on the walls of the opening. Installation of formwork is carried out from the boards or chicks of chipboard. When the design is installed, a frame of reinforcement is laid in it and concrete is poured. The formwork is removed only after complete drying of concrete. Although it is the most time-consuming way to install jumpers under the opening of the window or door, it is more economically more profitable. In this process, the involvement of special equipment is excluded for lifting heavy reinforced concrete structures.

Production of jumpers for window and doorways do it yourself in frame houses

The design of frame houses have less strength than brick or block, therefore the correct calculation of the jumper parameters for them is mandatory. The configuration of the window opening and the installation of its structural elements depends on the ratio of the width of the opening to the step with which the wall panels are installed.

Ideally, the width of the opening should correspond to the step of the installation of the racks, but often it is simply impossible. When used as a racks for any reason, the larger cross section of the installation of structural supports may be less than the standard window size, so it is necessary to build additional supporting elements to build jumpers of such openings.

If the width of the window opening is greater than the width of the setting steps, but does not exceed the double value, the installation of the jumpers is performed as follows. Two horizontal crossbars are installed between two extreme racks at the height of the opening. In a place where the stand should be, vertical struts are installed between the crossbars and the upper and lower beams. If the resulting opening is still too wide to install the window, then two more vertical struts are added to it at the same distance from the edges, forming the desired width.

If the width of the window opening is more than three spans, then it is mounted in the same way. However, to support short vertical struts, discolutions are installed. They are placed symmetrically from the center to the edges. Thus, one division must combine one short strut in the middle and two full-fledged racks.

In the case of a fivefold exceeding the width of the window opening over the width of the steak of the frame racks, the operation is performed as follows. The extreme frame racks must be double. External have the usual height, and the internal - should be height from the floor to the upper crossbar of the opening. The lower and upper crossbars are strengthened with a diagonal grid, by the type of ceiling farms.

Strengthening the opening of the bearing walls

Often, when redeveloping an apartment or house there is a need to do the doorway in the bearing wall. This is especially true of block houses in which all the default walls are carriers. Work with such structural elements should be carried out very carefully, since the calculated loads on them did not take into account the availability of openings. If in private home owner can make redevelopment and risk, then in apartment buildings such work should be agreed with supervisory authorities.

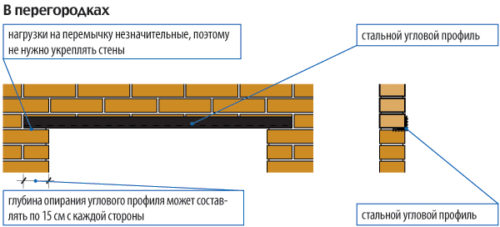

The dismantling process of the opening in the bearing wall begins with strengthening its arch. To do this, it is necessary to put markup of the outlook itself on the wall. Then, along the line of the arch, the depth of at least 100 mm are made. If the wall is brick, then it propyl is better to do in the junction of the brick series. First, it is much easier to do, and secondly, it is better to leave a full brick. Propyl can be done with the help of a grinder. Its length should be 100 mm more on each side than the width of the opening. The steel corners of 100x100 mm with a thickness of the shelf 8 mm are inserted into the propulsion.

After the corners are inserted, in each of them holes with a diameter of 8-10 mm every 250 mm are drilled. Holes with each of the sides must coincide. The re-diameter reinforcement rods are inserted through them. At the output from each hole, the rods are welded and cut flush. Now you can gently begin dismantling the wall. After 2-3 rows of bricks are removed, two corners in the end are welded with the help of steel strips. They are welded every 200 mm. After that, you can safely knock out the whole opening. So that his side of his ends began to collave, they are strengthened with the help of the corners. To do this, you can use the corners of 50x50 mm with a thickness of the shelf to 5 mm. They are also connected by steel stripes. With side parts, steel mortgages are welded to the corners, which are attached to the wall anchor bolts. The threshold of the new opening is enhanced by reinforcement and poured concrete. Now the opening will be strong enough to withstand any load that overlapping has it.

How to pour jumpers over windows with your own hands: photo