Bamboo parquet. Choosing and laying parquet from bamboo Floors

Bamboo flooring has long ceased to be exotic. Today it is used to design interiors of various style directions. It is not necessary to create an Eastern flavor - the bamboo parquet and classics will organically fit into the classics, and in modern.

Content

Production technology

For a more complete idea of \u200b\u200bthe material for a few words about the process of producing parquet from bamboo.

The initial raw material is a plant whose age is at least 5-6 years.

With the help of special equipment, the process of splitting on the strip with dimensions of 15x5 mm, after which they are digested and carefully dried.

Next, they are sequentially sorted, stained, polished and glued with the variance of the fiber guide the fibers by hot pressing. The final stage is the application of an additional protective paint and varnish solution, which has a positive effect on further operation.

Pros and Cons Bamboo Parquet

Like any material, the bamboo has its own number of advantages and shortcomings. But, we note that the first is clearly superior to the importance, thanks to which the parquet of this type is quite in demand.

Pay attention to the following list of advantages.

Dignity

- Environmental purity of natural material.

- High density (0,500 g / cm3) and strength (within 4.7-4.9 by brinell).

- A good level of deformation resistance (in the range of 0.11-0.13% to the transverse).

- Durability (standard warranty period - 30 years).

- High characteristics of heat saving.

- Antistaticity.

- Resistance to aggressive insect attacks.

- Affordable price.

- Attractive appearance.

- Easy to care for the surface.

We also note possible negative manifestations.

Disadvantages of bamboo parquet

- The possibility of natural spots.

- With high humidity, swelling is manifested.

- Fluster with prolonged exposure to direct sunlight.

- Despite the strength, linings are required under the feet of heavy furniture.

- Dark shades are less durable due to heat treatment in the production process.

How to choose a parquet bamboo?

From how correctly you will pick up the parquet, the appearance of the floor and the duration of operation will depend on. Therefore, with all attentiveness, come to solving this issue. Pre-analyze the market, for example, using the Internet, read about bamboo parquet reviews.

Main criteria

Company Manufacturer

In the process of choice, pay attention to large firms with a long stay in the market. They try to maintain their image, controlling the production process and testing the products obtained.

Category and price

According to the Russian standards of the GOST, parquet from bamboo should be quoted by class A. The price is often an indicator of quality, but you can find a completely acceptable option of a less promoted brand, the cost of the products of which will be several times less. To do this, pay attention to the technical characteristics of the material.

Type of panels

Three major varieties are widely popular at the current market:

- Bamboo piece parquet.

All elements are represented by straps with grooves or ridges on the ends and edges, which ensures the reliability of the clutch. Panels have a vertically or horizontally glued three-layer structure. If necessary, you can repeatedly restored. Perhaps laying pattern.

Standard dimensions of piece parquet - 900x90x15 mm, 600x90x15 mm, 960x95x15 mm. - Mosaic parquet. Its use is more limited to decorative work. Modules may have a different geometric shape.

- Massive bamboo parquet board. There are a panel with a horizontal structure of several layers (the amount varies to 5). The use of this type of material does not provide for decorative masonry due to linear length. About the parquet board from bamboo Reviews can be heard exclusively positive, but at the same time note that the source material is more expensive. Parameters - 2200x190x15, 1820x154x15 mm, 1200x120x22, 920x92x10 mm.

Make the selection of the most suitable material to the design project.

Humidity

Check with the help of a special tool - a moisture meter, which must be present at the seller. The standard indicator should not exceed 9%.

Geometry

Carefully consider individual planks, compare their shape. All items must have clear equivalent parameters. This criterion affects the convenience of mounting and the quality of the joints.

Length

Choose a parquet bamboo, taking into account the size of the room and the laying technology. The main limitations relate to the appearance of the appearance of the floor after the end of the work. For example, for a small room, it is advisable to apply a small-length parquet, mounted by its "square" or "christmas tree". If preference gives long elements - lay down floor "deck".

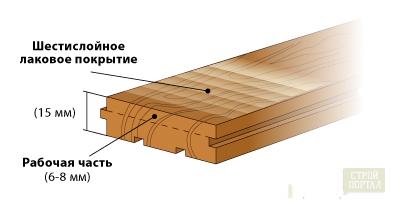

Working thickness

Distance from the front surface of the parquet panel to spike or groove. It will affect the future to wear resistance. Given the increased load on the floor in any operating conditions, it is important that this indicator meets the standards. For a parquet strip, a thickness of 15 mm, the indicator is 8 mm, for a thickness of 22 mm - 13 mm.

Colour

Check out the sorting, that is, the color tonality of several (ideally) elements. There should be no significant difference. Specific instructions to select the shade are difficult, it all depends on the color palette of the design of the entire room and your taste. Manufacturer companies deliver products of two main shades - light yellow (natural) and coffee (obtained by naturally heating material)

Varnished coat

Pay attention to the quality of the coating. It should not have irregularities, cracks, chips, scratches. Smoke panels: high-quality products do not smell, especially chemistry. Presented lacquer coating. Often three options:

- glossy

- matov

- rough-matte.

Quality certificates

Be sure to check their presence in order to eliminate the use of harmful glue solutions in the production process (phenol, formaldehyde). Pay attention to the production marking: the inscription "Guaranteed German (or other) quality" does not indicate the place of production, but clear engraving or inscription without errors "done in ..." is proof.

Package

All items should be wrapped in a heat shrink film and disbanded in boxes with straps inside or outside, as well as manufacturer logos.

Laying bamboo parquet

Installation of flooring in one of the methods - adhesive, which is described in more detail below or floating.

Instruments

To perform work, prepare all materials and equipment in advance. Make the presence of the necessary items with the following list:

- drill-screwdelt

- electropolitanzik

- dobochnik

- parquet hammer

- shlifmashinka

- roulette

- level

- toothed spatula

- plywood (moisture resistant)

- saws and parquet nails

- glue under Faneru

- parquet glue (without water!).

Preparatory work floor surface

The prerequisite for laying parquet is a carefully prepared smooth floor surface.

To do this, pre-follow these steps:

- Fill the cement self-leveling floor screed.

- Slide the surface.

- Wait for frozen.

- Check the surface smoothness of the surface (the maximum allowable deviation is 2 mm).

- Sprouter the surface, for example, primer (this will provide better clutch).

- Wait for drying.

- Cut the plywood sheets with a thickness of 12-15 mm into 4 parts.

- Make them, shifting each subsequent half of the sheet.

- Observe the gap between the sheets of plywood 5 mm.

- Enclose the substrate (the solution consumption is 1000-1200g / m2) and screw the screws (at the rate of one attachment by 5-7 cm or at least 15 pcs / m2).

- Collect Faneru (it will increase the adhesion between the surfaces).

- Make a 3-day break.

The process of preparation of material and premises

Regardless of whether you chose a natural parquet bamboo board or piece panels, you should prepare the material in advance.

To do this, do the following:

- No later than 2 days, get all the elements out of the box.

- Stir them.

- Leave indoors in the open form.

- Support throughout this time the temperature of 20 ° C and humidity is 45-50%.

- If the floor is being heating - disconnect it.

Installation of frames

Installing independently does not seem to be a problem. It is clear enough to observe the technological nuances. Below is the sequence of mounting bamboo parquet (photos will help to visually familiarize themselves with the instructions).

Technology

- Start the flooring from the territory opposite to the door, moving towards the exit direction.

- Leave the gap to the wall of 10-15 mm (this will help prevent swelling elements after installation).

- The junctions of adjacent boards displaced 50 cm.

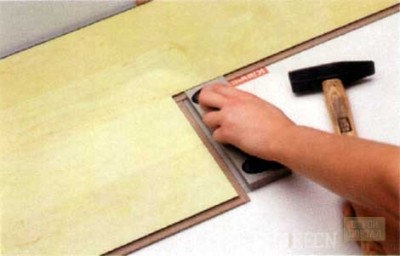

- When connecting the elements, slaughter their parquet hammer.

- Fix the slats through the grooves and spikes with nails at an angle of 45 degrees first with a hammer, and then Dobochnik and glue (approximate consumption - 1000g / m2).

- If the pipe laying is assumed - make an opening with an electrolovka with a radius of a 16 mm clearance.

- Close the hollows under the wall, left at the beginning of the work, B Fiberboard stripes.

- Start operation no earlier than 36 hours, preferably after 3 days.

Installation of plinths

Selection of plinths carry out in accordance with their vision of beauty. Start the installation from any angle or door.

Sequencing:

- Attach the plinth panels.

- Screw by self-tapping, observing the distance between them at 8-12 cm.

- Lach the resulting holes with colored wax, selected in the tone or stir up special point linings.

Video

The next video will help to clearly understand the entire installation process.

Conclusion

During operation, observe the simple rules for the care of the parquet:

- Support indoor humidity within 60%

- On the feet of furniture, especially massive, dress overlays from felt

- Cleaning perform a damp cloth, carefully unscrewed

- Regularly process the surface with special care products for the surface of the parquet

- After a certain period of time, update the lacquer coating.

Following these tips, you will save the attractive type of surface for a long time and its integrity.