How to make a bur for drilling wells with your own hands Instruments,Useful advice

When arranging the house in areas that do not have central water supply, sooner or later, it will have to be addressed about the regular flow of water into the house. Even if you use large tanks for the stock of water, they will need to constantly replenish, and it is unlikely to make your life comfortable.

Content

There is a way out in this situation - this is the creation on its site of an autonomous water source. Such a source can be well or well. Both the other hydraulic structure has a number of its advantages and disadvantages.

Drilling wells is not quite a simple task, but the volume of earthworks at the same time, is incomparable less than when digging the well. And, of course, the owners of the site with the house concerns the question: is it possible to drill a well on their own. After all, the work of specialists is not cheap and not always conditions on the plot allow you to call there special techniques.

If the aquifer lies at a depth of no more than 20 meters and the soil is soft, then the drilling operation can be performed independently.

Devices Bura for Wells

To drill the well, you must have a basic tool for this - the bob. Of course, the drill can be purchased in specialized points of sale, and can be made independently. To do this, it is necessary to know its design and main characteristics.

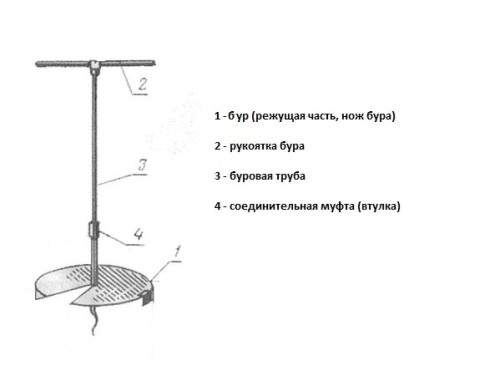

Based on all above, it is assumed to use a manual bora. Its main element is a drilling pipe.

- Drilling trumpet - It is a metal hollow structure, which should be able to increase the length, as deposit into the soil. An increase in the length of the drilling pipe is carried out by attaching additional sections. For the manufacture of the drilling pipe, it is best to use thick-walled metal pipes with a diameter of 40 to 80 mm and with a thickness of the walls of 2-6 mm. The segments of the pipe are made in length from 80 to 150 cm (depending on the growth of ease of use). The connection of the sections of the drill pipe with increasing its length occurs by the coupling or sleeve.

- Coupling -it is a short thick-walled pipe, slightly larger diameter than the main rod, with a thread sliced \u200b\u200b(or without that) and one end welded to each section. The connection is fixed with a pin or bolt with a nut.

- Sleeve — it is a short thick-walled pipe, slightly smaller diameter than the main rod, with a thread sliced \u200b\u200boutside (or without that) and one end welded to each section. The connection is fixed with a pin or bolt with a nut.

At the upper end, the drilling pipe must have a handle .

- Lever - This is a horizontal crossbar designed to rotate the drill around the vertical axis. It is made from a pipe with a diameter of 40-60 mm or other suitable material having a large safety margin. The handle is welded to one of the sections of the drill pipe or to attach to it in any other way (for example, inserted into the hole in the pipe). The length of the handle is chosen depending on the convenience of use, for example, to rotate the drill with two people can be sizes from 1.5 to 2 m. In addition, the length of the handle can increase in various ways. For ease of use, rubber tips, or tips from another suitable material, can be used at the ends of the handle.

At the end of the bottom of the drilling pipe, the cutting part of the structure is attached, called drill, knife or directly - boer.

Varieties of Bura

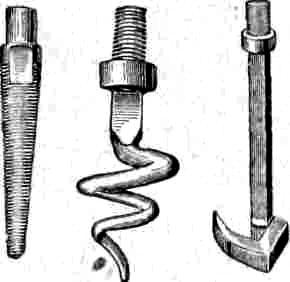

For homemade drilling devices, two main types of cutting fixture are chosen. This is a spiral bur and a spoonful burrow.

Spiral bur

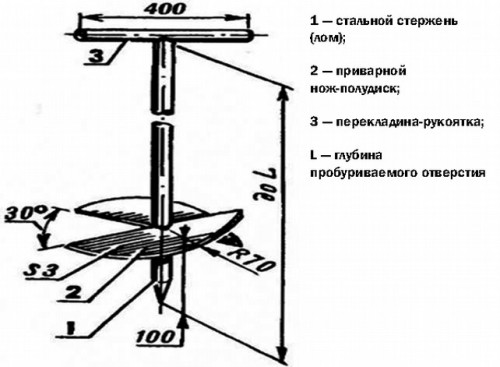

Spiral Bur has a second name - a screw burrow. It is a rod with a diameter of 40-60 mm from a durable metal with a pointed end and two knives of sheet metal (discs of plated in half) with a thickness of 1.5-4 mm, located at an angle of 20 degrees to the rod axis.

Such a type of a boraine may continue to be used for earthy garden and construction work of a small depth of penetration.

Spoonful

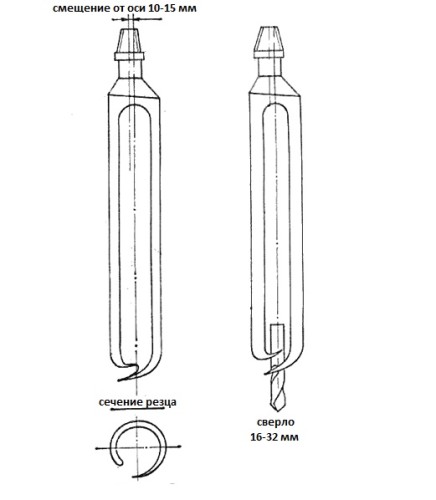

The corner of a spoonful type or a border is used for drilling, deeper wells than a spiral brown, a depth of 15-20 m. It is a metal cylinder from a thick-walled pipe. The length of the cylinder ranges from 60 to 100 cm with a vertical (sometimes spiral) slot. The pipe diameter is equal to the diameter of the well and is selected from the reasons of accommodation in the well the necessary equipment. The cutout in the cylinder is necessary to remove the soil from the side walls of the well. In the lower part of the cylinder, a thick drill with a diameter of 16-32 mm is welded or a narrow steel plate with a length of 10-15 cm to give and keep the drilling direction. The borae cylinder is located on a vertical bar with a displacement from its axis by 10-15 mm. The offset is intended to ensure that the diameter of the well was larger than the diameter of the bora. Such an eccentricity allows you to promote a spoonful boring inside the casing and carry out their installation in the process of drilling, which, in turn, protects the walls of the well from destruction.

What is necessary for work

First of all, for the manufacture of a drill with their own hands, you will need the skills of the welding and ability to qualitatively weld metal parts operating under conditions of high load.

To independently make a boring, prepare the following materials and tools:

- metal pipes of the required diameters for drilling pipe, couplings, bushings and handles (or ready-made clutches and sleeves);

- metal cylinder and drill or pointed plate for a spoonful bora;

- steel rod of the required length for the tip of the bora

- steel plate (sheet steel 2-4 mm) or a ready-made disc (disc from a circular saw) for a spiral drill;

- bolts, nuts, rod for plots;

- welding machine;

- vice;

- bulgarian and various assignations disks 150 and 180 mm;

- if necessary, the tool for cutting the thread;

- rasp;

- electric drill;

- wrenches, hammer, screwdrivers and passage;

- roulette and marker;

- protective and welding glasses, gloves and overalls.

Making a bead with your own hands

For the manufacture of a drill, any of the species, first need to perform the following general actions:

- For the manufacture of the segments of the drill pipe with the help of a grinder, cut the pipe on the segments of 80-150 mm long.

- For the manufacture of couplings or sleeves, cut the pipe of the corresponding diameter to the segment you need.

- Using a special tool, cut the threads on the blanks under the coupling or sleeve.

- Electrodel Drill holes in clutches, sleeves and segments for hopps or bolts.

- Cut the steel rod on segments sufficient to use them as a pin.

- One of the sides of the plinth is in visets by 90 °, in another drill a hole for the latch.

- To one of the ends of each segment of the drilling pipe, weld (or attach in another way) a coupling clutch or sleeve.

- Make from a pipe or other prepared material the handle of the boraxy the required length.

- To one of the segments of the drilling pipe, weld the handle (or drill a hole in it to insert the handle) or attach it in any other way.

We do spiral bur

In order to make a spiral bur, follow these steps:

- Take one of the segments of the drill pipe and weld to the bottom of it (the opposite part with the coupling compound), or attach a pointed tip from durable steel by another way. If a steel rod was provided for this element of the drill, then sharpen it.

- Cut out of sheet steel, for the manufacture of a bore knives, round plates (or take the finished disc from the circular saw).

- Collect the sections of round plates with the use of the Raspile or special drives of the electric drill.

- Split into two equal parts (in half) round metal plates or circular saw disc.

- Collect the edges of the cuts.

- On the arcuate side of each plate with the help of the Raspil and the Bulgarians, make a flat or toothed sharpening (for knives made from the disk for the circular saw it is not required).

- We weld discs to the rod (pipe), against a friend, retreating 120-200 mm from the tip of the bora. The angle between the plane of the knives and the horizontal plane should be 20 °, between the knives of 30-40 °, and the angle of inclination to the axis of the rod (pipes) - 70 °.

Make a spoonful bur

In order to make a spoonful boring, follow these steps:

- In a cylinder from a thick-walled pipe, we roll the longitudinal gap (make a cut). What a bulk soil, in which drilling is supposed, the less the width of the cutout.

- With the help of a hammer, give the edges the necessary cross section.

- Clamp, with the help of a rashpil or a grinder, lower and lateral cutting edges.

- To the lower part of the boraner, weld the sharpened plate or cooked drill on the metal.

- To the top of the bora, brew the rod (section of the drill pipe) with a displacement from the axis 10-15 mm.

The construction of the Bura, after the manufacture, must be experienced in practice and eliminate the identified disadvantages. After that, you can paint, to give a more aesthetic type and corrosion protection.