How to insulate the floor without using electrical heating systems with their own hands Insulation,Floors

Since ancient times, mankind has tried to protect himself from the cold in winter, and from the heat - in the summer. To change the skull of a wild animal hanged before entering the cave, new thermal insulation materials came, capable of maintaining heat inside the housing. If you are a happy owner of a country house, cottages, apartments or any other living space, then starting to repair the premises, be sure to come across the insulation of one or another part. This process requires compliance with special technologies that are individual for each case separately. For example, a method of insulation of the floor of the country house is significantly different from the work in the apartment. Floor insulation technology without the use of electrical heating systems is quite simple, it does not require special skills and knowledge. Having done everything yourself, you will be able to save significantly, and the result will not be worse than others.

Content

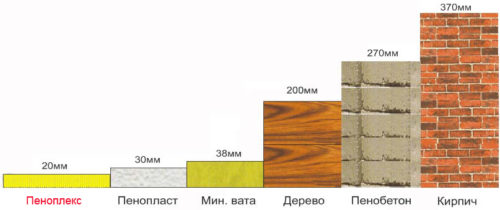

Characteristics of insulation

To date, the construction market is filled with all sorts of types of insulation and other heat-insulating systems that allow you to maintain and maintain heat in your home. All of them are intended for different parts of the structure, besides can perform various functions. Pay attention to all the features inherent in every species to choose the necessary one. If you are going to do everything yourself, we advise you to choose a good insulation option. You will save on the workforce, but you can spend on the material, then you will feel comfortable in the house, regardless of the time of year.

Selection of insulation for floors

Before you begin to arrange your floors, we advise you to carefully examine the existing materials that allow you to warm the dwelling. Each insulation system contains different materials, while can only be mounted in specific rooms. Relate all the advantages and disadvantages of each type to choose for yourself optimal, then the dwelling will fully maintain the heat that is so lacking in the winter.

The following materials are used as insulation for floors:

- Vermiculitis. To make this material, first mix two types of dark mica - biotit with flogopite. After that, they are mixed with liquid glass and carbonate filler, and then pressed. Weathered product obtained, recycled minerals. They are subsequently overgoed, and the vermiculite is obtained, which has excellent indicators of ecology. In addition, such a insulation is absolutely harmless to the human body. It is released both in a barn version with a stove thickness of 200-600 mm and in powder and liquid form.

Such a heater has a dense structure, since it has closed cavities of a microscopic species. This allows you to get rid of condensate accumulation, thereby increasing its service life. Vermiculitis has very high thermal insulation indicators, but it is worth considering the following - this material is quite expensive. The use of this heat-insulating material is not affordable to a person with a middle sufficiency. - Mineral wool. The appearance of convection in such material is practically excluded, since microscopic cavities do not let the air completely, in connection with this, the Minvata has low heat transfer rates. This insulation is much cheaper than the previous one, but not worse. He has one more feature - when laying vertically, the material can crawl, while losing its useful properties. It is better to use this material on horizontal surfaces, or concerned in advance about the additional fixation of the wool.

There is also an aluminize option of Minvati. The mat is closed with one or both sides with a special aluminum or metallized coating. This somewhat increases the cost of the insulation, but perfectly increases its useful properties. With proper laying, such a material does not require a vapor barrier layer, and the dew point can be forgotten. If there are two layers of aluminum foil, the temperature regime in the mineral wrench is aligned. This is due to the fact that each layer of the film forms the effect of the heat screen. The minimum thickness of the aluminated mineral wool is 6 mm, which is significantly less than the usual option. Please note that it is better to work with this material in protective glasses, a respirator and gloves, since the mic champions contained in the insulation can enter the respiratory organs and the mucous membrane, which is extremely unacceptable.

- Styrofoam. The material is perfect for the insulation of the floor by lags. It has a solid dense structure, which makes it possible to exclude convection. In addition, the foam is environmentally friendly, and the condensate is not formed on such a coating. It is important to note that this insulation is very cheap and harmless, but also has its drawbacks. Polyfoam is a fragile material because it is easily subject to mechanical exposure. In addition, moving the point of dew inside buildings from aerated concrete and a seven, most likely, the foam does not cope with this task fully. For the arrangement of the wooden floor in a dry room, such a material will be perfectly suitable, but requires a mandatory finishing decoration with decorative flooring.

- Ceramzit.The material is pieces of clay of a rounded form with the addition of aluminosilicate filler, which burn. Ceramzite is often used for insulation under the screed, because it has a fairly low cost, while durable and durable. The advantages of this insulation can also be attributed: environmental friendliness and poor thermal conductivity. But it is also worth mentioning that the pellets of the ceramisite have high hygroscopicity indicators, absorbing up to 20% moisture, and this already talks about the shortcomings of this material. Before equipping the floor, using this insulation, take care of high-quality vaporizolation.

- Organic insulation.Sold both in a piece variant and in a roller. In order to make the material, the fibers of flax and jute are used, thanks to which such a insulation is often called fibrous. It is most often used as a lining for laminate. But note that the natural version of the insulation can begin to rot from moisture, and synthetic - to spoil over time. But it is convenient to work comfortably and quickly, besides, it has similar properties with mineral wool.

- Polyurethan. An excellent way of insulation of sex, requiring special professional equipment, as it implies the use of a sputtering method. The insulation is a liquid similar to the composition with the mounting foam, which is sprayed onto the coating. The main disadvantages are considered: high cost and subsequent expensive finishing finish.

- Self-leveling insulation.It is a dry or liquid mixture, which flooded the floor without additional preparation. The solution has a very high cost, since it is complex. This material is more suitable for floating floors in expensive mansions, or high-class hotels.

- Granborobeton. It is a mixture of cement-sandy solution with a filler of the granular type (clayzit, foam, vermiculite, stone crumb, etc.). The method of insulation is quite simple and cheap due to the low value of the material. But heat-insulating properties and the strength indicators are much higher than, for example, in foam concrete. Frequently used for the insulation of the top layer of a two-layer screed for floors, under which the basement is located.

As you can see, a list of materials that can be insulated with a room, quite long. All of them will be in one way or another to perform their useful feature, it all depends on where you will apply them. Match the feature of each type with the location of the future insulation, then the coating will last for a long time, and winter will not seem so cold.

Popular Floor Insulation Methods

For the construction and decoration of premises of various kinds, various building materials are used. Whether it is a bath, a balcony go a private wooden house, the heat insulation process will be varied. The thermal insulation materials can not always fulfill their purpose, since there are cases that they are mounted, not paying attention to the laying technology. Mounting technologies for the insulation of floors for a wooden and monolithic house are different, as they imply work on different surfaces, using the insulation of different kinds of different kinds.

Wooden floor insulation in the country

When it comes to restoring the flooring at the cottage, it is important to pay attention to the state of the floor. Warming up the floor in the country, be sure to check the building for the presence of basement and nearby groundwater. In case of their immediate vicinity, the old coating is better to replace, since the likelihood that the floor has rotted quite high.

To insulate the wooden floor in the country, without using the electrical heating systems, they come as follows:

- Remove all the foundation bars to get rid of yourself from the doubts related to the quality of wood. Since the bar may contain cracks, and in some places to do, then you can simply not notice this. In this case, it is better to replace everything right away.

- Treat dry wood that you will use to arrange the floor with special means. They will protect the floor from rotting and harmful insects. It will not be superfluous to miss the bars with special fire-bioprotection.

- Clean the surface from garbage and wood residues. Treat the planting places with bitumen waterproofing or resin. Also perfectly suitable fat wrapper. In places where laugs were installed, mounted new ones. It is best to pull a few loaks in the level to set lags in the same plane. Fix the lags from the ends in the mounting sockets using dry gravel. Check out the plane once again, after which the floor is filled with gravel and cement-based concrete solution. Give the concrete to completely grab.

- We begin to fill the draft floor. For this, it will be suitable no-puzzle boards with a thickness of more than 20 mm and a width of 100-200 mm. We also need a 50x50 mm bar, which must be fastened to thick bars of the floor base. Use for this vehicle tapping screw 4.2x105 mm. After the bread makeup is mounted, start to nourish the draft boards. Use nails for this, but note that the draft floor should not be nailed to lags, so use nails with a length of 50-60 mm. Places of location of the foundation bars mark on the wall or draft floor with a pencil.

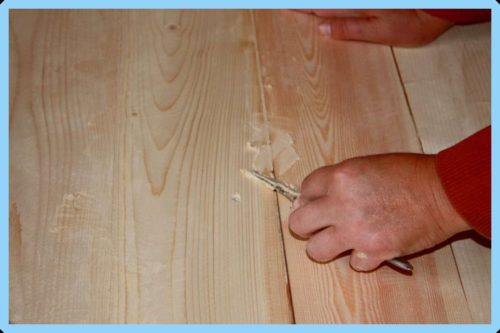

- Do not forget about the preliminary impregnation of the draft floor. In case you forgot to do this, process on the already mounted design. Try the boards to be mounted tightly. Often, thanks to the irregularities of the joints, gaps can be formed between the boards. It is not scary because they will be covered afterwards insulation. A permissible width of the slit - 10mm. That the floor does not creak, the slots can be treated with sealant.

- Oddly enough, but we need to mount lags again. They are installed in terms of 1000 mm increments. For this, the timer is perfectly suitable with a width of 150 mm with a wall thickness of 50-75 mm, it all depends on the intended load on the floor. For reliable fixation of the lags, use the tree screws, while note that fasteners should be included in the foundation lag at least 25-30 mm.

- Now it is necessary to protect the draft floor from the penetration of moisture. To do this, we chose a membrane type of film waterproofing, which is best suited for work on such a surface. Place the material so as to maximize the joints. In case of their appearance, glue with a wide moisture-resistant tape. The film should not be stretched, it is better to leave a small amount of waterproofing on providing.

- The choice of the size of lags is due to the thickness of the selected insulation, as well as future loads on the floor. Mounting a larger bar, note that the insulation of such a gender will require thermal insulation material.

- Start laying insulation in the lumen between lags. We are not in vain chosen a step of 1000 mm, since most insulation has a width of 1 m. Thus, we can avoid a huge amount of trimming, thereby speeding up the process of insulation of the country's gender. It is necessary to fill all the lumens so that there is no cracks, and the material did not drank above the level of the lag, and it was better to flush.

- Now you can lay a clean floor. Perfectly plywood, OSP panels or a lap board. Selection of finishing finish leave for you. It can be: laminate, parquet, linoleum, tile and other types of finishing materials.

As you can see, the insulation of the floor is quite labor-intensive occupation, because it requires the correct sequence of actions. Do it all gradually, choose the right material, and do not forget about pre-processing. Properly conducted installation, allow the floor to serve for a long time, having relived you from headache related to the replacement of rotten lags and boards.

Concrete floor insulation in the apartment

Thermal insulation materials have a wide range of applications. They are insulated both wooden and concrete surfaces. Also, the insulation perfectly cope with the protection of the facade from external factors. When it comes to a residential room, in particular - about the apartment, then without the instruction can not do.

If you decide to warm the concrete floor in the apartment with your own hands, then perform everything consistently by sticking to the next algorithm:

- Spend floor waterproofing. Mix a dry solution with water in the proportion specified by the manufacturer. If you use the finished mastic, then begin to immediately apply the mixture to the surface. Use a wide brush so that the surface is fully processed, then let it dry.

- Additionally, it can be mounted on the perimeter of the room by damper tape. It will protect the wall connection of the wall and gender from the penetration of cold and moisture. On the prepared floor you can also lay a layer of pholoisol without a substrate. It will help keep warm even longer.

- Place the insulation to the surface of the floor. For this, foam or high density polystyrene foam is suitable. Also with thermal insulation perfectly cope with dense mineral (stone) wool. Lock the slab using the thermotubels to the floor.

- On top of the insulation, put a metallic armopoyas 1000x2000 mm. The cells in 50x50 mm will be enough, but you can use the grid with a cell 100x100 mm.

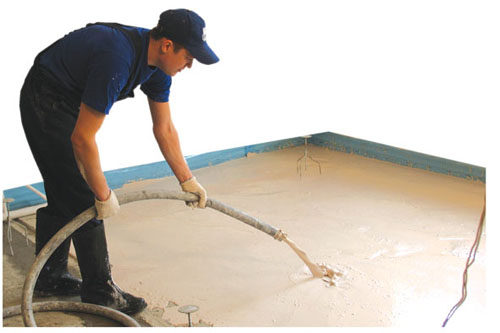

- Align the floor with a screed, if the surface has large differences. Place the beacons for the solution. Planks should be in the overall horizontal level so that the floor is smooth. Use the rule and level. Pour the solution between beacons, smoothing the rule.

- When the solution was removed, you can additionally insulate the floor, setting on top of the OSP plate or Phane.

- Now you can proceed to finishing, which is entirely dependent on your fantasy and wallet thickness.

To insulate the concrete floor in the apartment, whether it is a living room or a balcony, you will not need special skills and efforts, it is only important to comply with the correct sequence when performing work, then warmly in the winter period is provided to you.

To better figure out the word insulation, we advise you to see the following video: