How to harden glass Useful advice

Glass is a very beautiful finishing material that is often used in the construction of buildings, showcases, furniture, doors, decorations of houses and apartments, in the production of cars of any kind. But ordinary glass is not suitable for all these purposes, it is very fragile and can easily crash. Instead, it is necessary to use absolutely safe material - tempered glass.

Content

Feature material

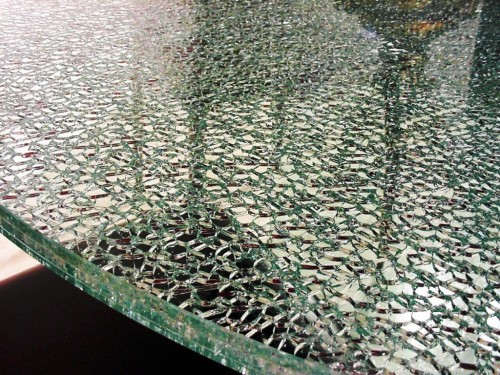

Hardening glass is such a processing of a material that makes it 5-7 times more stronger, it can withstand the temperature differences from 60 ° C to 300 ° C. After hardening the glass becomes an inhomogeneous subject that cannot be cut, drill a hole in it and even smash. It resembles a ball inflated by air - no matter how you tried to cut it into parts, he will eventually burst. According to the quality standards, tempered glass with a size of 50x50 mm when exposed to a sharp metal object to 75 g should crumble at 40-50 fragments.

Advantages of tempered glass:

- The strength of the tempered glass is 5-10 times higher than usual, on bending - 2-3 times higher.

- Operation is allowed at temperatures from -150 to +300°WITH.

- The most important advantage is safety. In case of destruction, tempered glass forms a lot of small rounded fragments that cannot be broken.

- Durable material, which without special destruction will serve you for many years.

- It has a very beautiful design, which is often used when designing modern furniture, doors and partitions in the apartment.

- It is possible to make both transparent and matte glass of any color, with a pattern or without it.

What the tempered glass looks like can be seen in the photo.

Ways to harde glass

There are two ways to harde glass:

- the chemical method is the process of replacement of small sodium ions by large potassium ions. This method is practically not in demand in our time;

- thermal method is the process of heating and cooling the glass.

Tempered Glass Production Technology

Glass hardening technology is the rapid cooling of the material from the temperature, which is above the melting point of the glass. At the same time, a high voltage is created inside the material, which makes the glass resistant to all mechanical effects. For greater efficiency, it is recommended to use the hardening environment, which has a higher cooling possibility plus a change in heat exchange characteristics. The most popular such medium is air mixed from the blowing lattice, which is able to change the type of cooling - from natural cooling to forced cooling and vice versa.

In addition to air, liquids that are able to give acceleration of heat transfer can be used as an efficient hardened medium, so that the thickness of the tempered glass is small, and the TCR is lower. The degree of hardening will be above 4 pores / cm.

It can be:

- mineral oils;

- silicon fluids;

- melted salts and metals.

The disadvantage of the use of mineral oils and silicone liquids can be a poorly adjustable cooling process - falling on them, hot glass causes boiling, which leads to a sharp change in the thermal return of the material.

The manufacture of tempered glass with the use of metal alloys is characterized by the following indicators:

- a higher thermal return ratio than in the case of the use of organic fluids, which is especially sensitive at very high temperatures (from 600 ° C);

- it is allowed hardening glass with low troll;

- possible hardening with high glass transition temperature;

- ability to harden matte glass.

The disadvantages include high density of the medium, which makes it difficult to immerse the glass into it.

Glass hardening equipment

To date, the technique stepped as far away that allows you to make and harden the glass of the most complex shapes and sizes. One of these modern equipment is the horizontal hardening system of glass. With it, you can get tempered glass, the dimensions of which will be a maximum of 2100x3000 mm and from 4 to 12 mm thick.

The advantages of such a system include:

- Closed-type elements are used, which are heated to a temperature not higher than 750-780 ° C. This makes it possible not to get a glass of thermal shock, improves its characteristics and quality, and the equipment itself increases its service life without overheating. When open-type elements, heating is needed to 1000-1050 ° C, which is more dangerous.

- High reliability in such equipment provides a drive that maintains the destruction of the glass into the hardening process.

- Repair of the system is allowed, since all the main elements of the furnace are in the availability zone.

Steel Glass Production Operations

Before hardening the glass, it must be properly prepared. The whole process from glass preparation Before shipment of tempered glass consists of the following operations:

- selection of high-quality glass for hardening and rejection of unsuitable glass;

- cutting glass according to pre-drawn drawings;

- grinding the edge of the glass;

- drilling holes for fittings and fasteners;

- washing and drying blanks;

- quality control of blanks;

- labeling;

- process of hardening glass;

- quality control of the obtained hardened products;

- packaging, shipment and sending finished products to the customer.

Glass hardening process

The process of hardening glass itself consists of three stages:

- Heating glass. The surface of the glass is warmed up to a temperature approximate to the melting point of glass. The glass begins to deform, but not soften completely.

- Fast cooling glass. At this stage, the surface of the glass is already cooled, and within the substance continues to be heated and slightly viscous.

- Full cooling glass. The tempered glass continues to be cooled to a complete cooling at room temperature.

Tempered glass cannot be cut, because with such a mechanical impact on it, it is necessarily crushed.

Applying tempered glass

The scope of tempered glass is very extensive:

- window and door windows;

- partitions and showcases;

- stair marches and steps;

- railing and visors;

- automotive production.

Glazing of shopping centers and residential premises

The facades of modern shopping centers and residential buildings are made in most cases glass. This uses double-glazed windows in an aluminum profile. Such structures skip more sunlight, but prevent the penetration of ultraviolet rays into the room. In addition, they are able to hold heat. Also, most partitions and shop windows are made of glass, it is very well expanding internally space. In this case, glass can not only be transparent, but also matte, color or with any decorative pattern.

Glass showcases

Glass showcases attract buyers more than ordinary walls even with the most beautiful signboard. For the manufacture of such windows, one-piece tempered glass or several glass parts are used, it depends on the size of the showcase itself.

Glass doors and partitions

Doors and glass partitions - new style in modern design. It is not only beautiful and cozy, but also safely and securely. From tempered glass you can create unusual designs - sliding and pendulum. The glass doors allow you to visually increase and expand the inner space. Especially important is in small apartments.

In the production of furniture, tempered glass also found its application. It is used to make surfaces of tables, doors of cabinets and other elements. Especially often use tempered glass into the kitchen as apron.

Is it possible to harden the glass at home

Many often have a question - how to harden the glass at home? Unfortunately, this is impossible due to the fact that the process requires a high temperature, which is impossible to achieve at home. The only thing you can afford is to harden the glasses so that they do not fight so much. To do this, it is necessary to immerse the glasses in the container with water and give it boiling. Then reduce the fire and boil the glasses for 5-6 hours, then remove the container from the fire and shut a dense cloth. After complete cooling, the glasses can be removed and use on purpose. They will be more durable and will withstand any boiling water.