How to warm up concrete Useful advice

Concrete - building material, without which building buildings, repair of apartments and houses is impossible. Warming up the concrete is a serious process, so it is important to know all the manufacturing technology in order to get high quality and durable as a result, and the most important durable material.

Content

Warming up concrete options

- Warming concrete wire.

- Warming up concrete cable.

- Warming up the concrete with a welding machine.

Warming up concrete wire

Warming up concrete wire

To warm up concrete, a simple and relatively inexpensive PNSV heating wire is used.

The wire consists of two elements:

- One-filling steel lived, round shape.

- Insulation - PVC plastic or polyethylene.

The method of warming up concrete wire is based on the transfer of heat to concrete from highly heated wires. Wire heating is carried out using lowering transformer substations that have the adjustment system. Such a system is very convenient, it allows you to adjust thermal power on the basis of external temperature changes.

Concrete Warming Technology Wire:

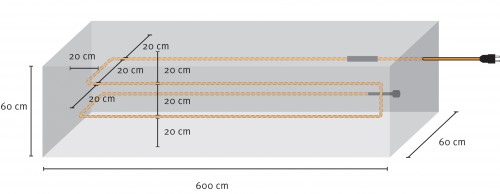

- The wire is laid evenly into the design, and it should not touch the formwork between himself, does not touch the formwork and do not go beyond the levels of concrete.

- The output of the ends beyond the heating is carried out after connecting the heating wire and the cold ends by the method of their soldering. Place the soldering is recommended to wrap metal foil to save the heat field.

- The number and length of the heating element is calculated based on the prepared technological documents and cards.

- A test check of the wire of the megommeter is carried out to ensure the uniform load of the current in phases.

- A current is served through a reduced transformer substation.

How to calculate the heating of concrete when using different warm-up methods? Almost all methods take into account: type of structures, the total area of \u200b\u200bheating, the volume of concrete and the required electrical power.

The amount and length of the heating element is calculated on the basis of the design of structures, the area of \u200b\u200bheating, the volume of concrete and the electrical power required for this.

When working with the heating of concrete, the wire is necessarily developed by the technological map separate and individual for each design. Regular laboratory observations are conducted, taking care of the heating time and time of pouring concrete.

Warming up concrete Cable

The method of warming concrete Cable does not require large energy consumption and does not need auxiliary equipment.

Concrete Warm Technology Cable:

- The cable is installed on the base of concrete before the fill of the solution.

- Fixing fasteners.

- The cable should not be damaged during the installation and operation and should not be intersecting with each other.

- Connect the cable to the low-voltage electrical cabinet.

When using a cable to warm the concrete, a cable installation diagram is compiled and temperature tests are conducted.

Warming up concrete with welding machine

The method of warming up the concrete with a welding machine includes the use of: pieces of reinforcement, incandescent lamps and a conventional thermometer. The pieces of fittings are installed in parallel chains, with adjacent reverse and straight wires, the incandescent lamp is installed between them for measuring the voltage, and a thermometer is used to measure the temperature. Concrete time is very long and is more than a month. When heated in this way, the design should not be susceptible to cold and pouring water.

This method is used with small amounts of concrete and good weather conditions.

Warming up concrete in winter

In winter, the hardening of concrete ceases, as water freezes and does not participate in chemical reactions. It also occurs the destruction of the quality and strength of concrete. Therefore, the warm-up of concrete in winter is very important and necessary.

Methods and methods of layering concrete:

- Adding antiorrosal additives.

- Heated by the "Term" method.

- Other heating methods of concrete.

- Technological warming of concrete.

Adding antiorrosal additives

Antiorrosal additives withstand strong cold, even at temperatures -30 C perform their chemical testimony. The composition of additives is different, but the main component is antifreeze - a liquid that does not give water to freeze. For reinforced concrete structures and reinforcement floors, mixtures are suitable with the addition of sodium nitrite and sodium format. Their main feature is the preservation of physicochemical and anti-corrosion properties at low temperatures.

For product concrete, hollow reinforced concrete blocks, in the manufacture of borders and paving slabs, mixtures with the addition of calcium chloride are suitable. Properties of this substance are widely known all over the world. Due to the speed of hardening, resistance to low temperatures and a low price construction in winter has become available to everyone.

Chemical substance - Potash, ideal antiorrosal additive. Quickly dissolve even with a minimum amount of water, does not cause corrosion. The use of potash when heating concrete is a significant savings on building materials.

When using antiorrosal additives, it is necessary to comply with all safety standards. For example: it is impossible to use concrete with these additives, when the design is under voltage, monolithic flue pipes are erected, etc.

Warming up the "thermos"

The "Thermos" method lies in the fact that in a warmed formwork with a temperature of 20-25 degrees, concrete is stacked. Due to the outgoing heat, the design acquires strength. Also the common method is the additional heating of concrete, and then the room is already in the warmed formwork

Other concrete heating methods

The transformer warm-up method is similar to the warm-up method "thermos", only instead of conventional heating, the formwork is used by a transformer or wire.

Electrode heating occurs with strip, lamellar or string electrodes, which are immersed in concrete. The current is distributed through the electrodes through a lowering transformer.

Infrared Wipening Concrete is not immediately for the whole design, but for individual zones. Infrared devices are set to these zones, which consist of reflectors and directly from emitters. Infrared rays transmit thermal energy to the entire selected section of the structure. Due to lateral radiation, all cold places are heated.

Technological warming of concrete

The technological warming of concrete is based on the transmission of current through the cable or wire, which are installed on the design before pouring concrete. The ends of the wire or cable are connected to the transformer, then heat is served. The voltage level is adjustable according to the established and developed project, and necessarily accounted for; Design area, weather conditions, concrete brands, wire lengths.

Warming up concrete in winter conditions necessary component for any construction work. There are many different schemes for the warm-up of concrete and the choice occurs individually for each design.