Laying the substrate for laminate Floors

Laminate laying technology assumes the mandatory use of the substrate. This allows you to extend the life of the decorative coating and gives a lot of other advantages during operation. All of them are aimed at improving comfortable conditions in the room. How kind of types of substrate are how to choose this material and how the laying of the laminate substrate should look like in each case, you will learn from this article.

Content

- Why do you need a substrate for laminate?

- Choose a substrate for laminate - Requirements

- We choose the material of the substrate

- Polyenethylene substrate - reliably and cheap

- Substrate from foamed propylene - budget option

- Foil and composite substrate - new solutions

- Cork as a substrate for laminate - Universal solution

- Coniferous breed substrate - expensive, but reliably

- Laying the substrate under laminate - video

- Conclusion

Why do you need a substrate for laminate?

A properly laminated substrate for laminate simultaneously performs several functions:

- Provides the required depreciation level when walking, due to which the risk of panel savings and the formation of an additional noise background is reduced.

- Increases the quality of noise insulation, so that the intensity of vibrations is reduced when household appliances.

- Eliminates minor small defects, such as deviations horizontally surfaces.

- Prevents premature destruction of laminate under the influence of drops of moisture and temperature - serves as a barrier.

- Increases the thermal insulation properties of the floor covering.

- Promotes the correct distribution of pressure load throughout the canvas, which also eliminates its deformation, the appearance of festers, cracks.

Important! All these characteristics will meet the highest indicators only if the laying of the substrate under the laminate will be performed correctly.

Choose a substrate for laminate - Requirements

Since the modern building market presents a wide range of materials of this destination, it is not always possible to choose the appropriate. To simplify the task, decide in advance with your requirements based on the following criteria:

- The conditions of the temperature and humidity regime in your room.

- Permissible budget.

- The thickness of the laminate itself - from this will depend on the preferred thickness of the substrate.

- The desired origin of the material is natural, synthetic. The degree of its environmental purity.

- Easy technology laying substrate under laminate.

We choose the material of the substrate

There are several types of substrate under laminate, which differ not only by laying technology, but, first of all, the basic material.

You have to make a choice from such options:

- Cork.

- Polyeneetylene and Painropyne.

- Substrate based on coniferous rocks.

- Composite materials - foil, rubber and bitumen substrate.

Important! Do not hurry to give preference to the best in your opinion the material. Before making a purchase, carefully read the technical characteristics of each material - which of them are very important for you, and which are not very, pluses and cons of products. Also specify how to lay a substrate for a laminate in a particular case and relate your own professional skills, temporary features with the features of technology - how suitable it is for you and do not have to spend additional funds to call qualified profile craftsmen. Consider such a factor: if you chose a cheap laminate, then you can take an expensive substrate unprofitable under it, and vice versa.

Polyenethylene substrate - reliably and cheap

Polyeneetylene is widely used in different directions of construction. Despite the fact that this material is completely synthetic, its technical characteristics determine its popularity.

Pluses of substrate

The advantages of using a polyethylene substrate under laminate are as follows:

- Excellent antibacterial properties - in this material there are no favorable conditions for the development of all kinds of pathogenic bacteria, including mold fungi do not affect the substrate or the laminate itself. So it is a completely safe option for a person.

- Resistance to destroying under mechanical exposure - here is meant the risk of breathing holes with rodents. Polyeneetylene is uninteresting with such animals and insect, so you boldly choose to arrange a private house.

- Absolute moisture resistance.

- Excellent thermal insulation properties.

- Resistance to chemical exposure, including solvents, oils, which makes it possible to lay such a substrate directly on the concrete base of the draft floor.

- Low price.

Minuses of the substrate

The complex of all the advantages of this material makes it almost perfect. The imperfection of polyethylene is manifested by the following disadvantages:

- Risk of destruction with constant exposure to sunlight.

- Reducing elasticity after a long period of operation.

- Synthetic base.

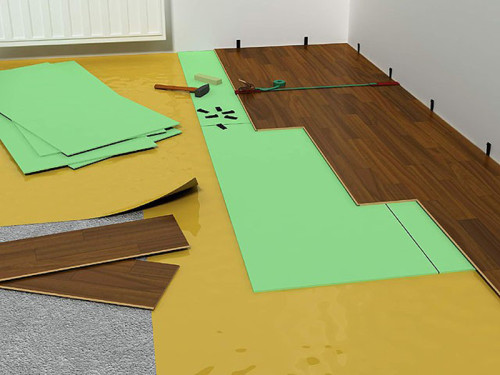

Laying the substrate

The technology of how to sharpen a substrate for laminate from Polyeneetylene, is very simple:

- Roll the material over the entire floor of the floor in the room with stripes.

- Fix them with assembly scotch.

Important! The recommended thickness of such a substrate under the laminate is 2-3 mm.

Substrate from foamed propylene - budget option

Foamed propylene is the most affordable material from all existing options for a group of substrates. Despite the low cost, its technical characteristics are at the height.

Important! The question is how to put the substrate under the laminate, in this case it is solved in the same way as when the polyethylene material is selected.

Pluses of substrate

- The porosity of the structure, which guarantees good depreciation, noise and thermal insulation, breathability.

- The condensate accurate on the inner layer adjacent to the draft floor is excluded.

- Good moisture resistance.

- The optimal resistance to damage mechanically, including insects and rodents.

- An acceptable service life - up to 10 years.

Minuses of the substrate

- Combustion.

- When heating and other adverse effects, emissions in the air of toxic substances are possible.

Important! Given the shortcomings of foamed propylene, it is impossible to say with confidence that this is the best substrate option, but its cost is often becoming a determining factor when choosing a substrate for laminate. If your home has a good fire protection, as decor you have chosen inexpensive laminate and you plan to update the interior in the next couple of years - then yes, such a substrate will become quite appropriate solution.

Foil and composite substrate - new solutions

The foil substrate is allocated by a separate group among propylene materials for the reason that the additional layer provides higher operational characteristics and reduces adverse effects.

Composite substrate is also a multi-layer material that includes other components:

- 2 layers are polyethylene of a different chemical composition;

- 1 layer (medium) - granulated polystyrene foam, which is used for filling.

Important! The characteristics of this material are high in all parameters, despite the fact that the thickness of such a substrate is no more than 3 mm.

Cork as a substrate for laminate - Universal solution

Laying the cork substrate for laminate is the most popular way to solve the problem of material selection. A wide range of species, the natural origin of the foundation is just some of the indisputable advantages of such a kind of substrate.

Sizes and shapes of cork substrate

- The canvas in rolls with a length of 8-10 m, 2-8 mm thick.

- Plates with a thickness of 1-5 mm. The dimensions of the modules are 30 * 60 and 60 * 60 cm.

Types of cork substrate

- Push plug substrate.

- Substrate from traffic and bitumen.

- Substrate from traffic and rubber.

Important! The differences between these three types of cork substrate are in the component composition and manufacturing technology:

- An ordinary tube substrate is made of fine wood chips by pressing.

- The bitumen-cork is based on kraft paper, which is impregnated with a bitumen composition and sprinkle with a cork.

- The rubber-cork substrate has a polymer in its composition, cork crumb and rubber granules, which are mixed into a single mass and are molded into sheets.

The last 2 species refer to the category of materials of the last generation, that is, in all specifications they have the highest rates compared to other varieties. But at the same time, the price of such material is an order of magnitude higher.

Pluses of cork substrate

- Maximum high strength.

- Durability - service life is at least 20-25 years.

- Absolute environmental purity.

- Resistance to rotting, any mechanical exposure.

- Elasticity in combination with long-term preservation of elasticity, which guarantees high-quality depreciation, noise and thermal insulation properties throughout the entire period of operation.

Important! The additional advantage of such a warm substrate is that it is possible to hide even the essential roughness of the draft floor.

Minuses of the substrate

- Increased moisture absorption, which causes specific requirements for the conditions of the room - the absence of significant temperature differences and moisture.

- Rubber and bitumen are combustible materials.

Laying cork substrate

Laying the cork substrate is also quite simple:

- Sheets or rolled coating strips Stay online.

- For fixing, use the mounting tape, the width of 5 cm.

- When the moisture differences in the room additionally laid the waterproofing layer on the draft floor. For this purpose, a polyethylene film with a thickness of 1.5-2 mm is suitable.

Coniferous breed substrate - expensive, but reliably

The coniferous substrate is a slab modular material. The basis of it is wood of certain breeds, which causes its higher cost. But at the same time, the laying of the coniferous substrate takes a minimum of time and is an easy task even if you do not have any skills and experience in building work.

Pluses of substrate

- Absolute safety and environmental purity due to the natural wood components of the material.

- Excellent wear resistance and high strength characteristics.

- High degree of protection against noise and heat loss.

- Optimal density and elasticity, which practically completely eliminates the risk of deformation of the substrate, a sagging or formation of drops of the height of the floor covering, even after long-term operation.

- Resistance to moisture.

Minuses of the substrate

- Natural wood creates favorable conditions for breeding insects, especially if it is a private house.

- High price.

Laying the substrate

Laying the substrate under laminate - video

Conclusion

As you can see, materials for laying a substrate under laminate a lot. Each of them has its own number of advantages and disadvantages. Therefore, before you finally decide what option it is suitable for you, designate more important characteristics for yourself, given the specific conditions of your room. For example, if you have excellent fire protection, the house is not subject to attacks insects and rodents, and you have chosen the laminate, then it is advisable to take a coniferous, cork or artificial composite material for the substrate. If the primary task is to make repairs as low as possible - then this is a foamed propylene or polyethylene.

Remember another condition for achieving a qualitative result - choose products of a reliable, proven manufacturer, be sure to check all the quality certificates of the proposed samples, and when buying, do not forget to check the entire volume of your substrate for the absence of defects. With this approach, even the cheapest substrate will last you for a long time!