Welded gates do it yourself Useful advice

The gate for its own estates is one of the most important bonding elements. Properly manufactured and installed gates will not only provide security, but also convenience when driving your own car. As a rule, this part of the fence is made of metal by welding. The welded structure has excellent strength and operational properties, and at the same time has a relatively small weight.

Content

The simplicity of the design and the possibility of manufacturing the welded gate itself, makes this option one of the most attractive. About how to make a welded gate with your own hands - Next.

Options for Welded Gate Designs

The choice of a variant of the welded gate depends on several factors:

- First of all, from the entire architectural ensemble. Naturally, if the gate is planned to be installed at the entrance to the territory of a large manor with a large mansion, then they must be high, massive with elements of artistic forging. And, on the contrary, the wrought-welded gate, installed on a small summer cottage, will look ridiculous.

- Also choose the option of the gate depends on whether the car is in the family, which size it is and how often it will be used. The size of the gate should allow without any problems to leave even with adverse weather conditions, while without damaging the car. If you plan to often enter and leave to the territory of the house, it is advisable to install the gate with the automatic opening mechanism. It can be a retractable or swollen gate. Moreover, the mechanism of opening the gate can be carried out from keychain in the car, which is very convenient with adverse weather.

- Availability of wicket. If the width of the site does not allow you to place the gate and the entrance gate separately, which is often in conditions of dense urban development, then these elements can be combined. In this case, the wicket is installed directly in the door canvas. If the wicket will be located separately, it must match the overall stylist with the gate.

Types of welded gates

By the opening mechanism, the welded gates are divided into:

- Swim welded gates. Most often consist of two halves, which swallow deep into the site. The advantage of such a design is the lack of restrictions in height. However, swing gates, depending on their weight, require massive columns as a support. To the same way, the automation of such a model is much more complicated, as it requires working with each sash separately and synchronize their movement.

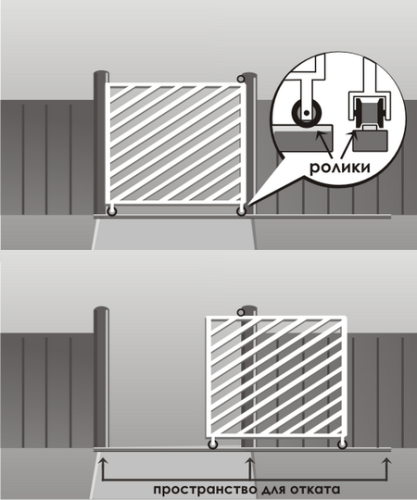

- Skump. Retractive welded gates open in the sides. According to its design, they are divided into three types:

- suspended. This type of gate is distinguished by the suspended design of the sash, which is suspended on the upper beam. The disadvantage is the height limit that can make it impossible to travel some cars;

- stubborn. The movement of the sash of such gates occurs on the rail laid on the ground;

- console gate. Such models are quite complicated and without the help of a specialist to mount them quite difficult.

Safety in welding work

When conducting welding work, it is necessary to clearly comply with the safety requirements:

- Performing work is obligatory is the use of workwear and SIZ, the main of which is considered a mask to protect the face from the action of ultraviolet. Otherwise, problems with eyes will be provided. Special footwear, hand protection tools will be removed by the welder from entering the rolled scale during welding.

- Work is necessary in the fresh air or in a well-ventilated room. Smoke from molten metal, and dust adversely affect health.

- Be sure to provide for the presence of a fire extinguisher. It is better to use a carbon dioxide model.

- When carrying out welding work, it is impossible to prevent electrode overheating. The first sign of overheating is the redness of the electrode, which is a consequence of too high.

- Be sure to check the condition of the wiring, as the welding machines consume a large amount of electricity, which can lead to a trip. If the device is connected to the home network, it is better to disable all household appliances at the time of welded work.

- Before starting work, it is better to check the condition of cables and a welding machine. Cables should not have obvious signs of damage.

Making welded swing gates with their own hands

Before starting work, it is necessary to decide on the design and material from which the gate will be made. The most optimal option can become a frame gate made of profiled pipes, trimmed by professional flooring. This option is distinguished by low cost and relative ease of manufacture.

Each gate sash is a frame, scored from the profiled pipe and amplified with diagonal and horizontal separations. Strengthening the design will make it more holistic and prevent sediment due to the reduction in the load on the welding seams. Outside, the frame is trimmed by a professional flooring, which is painted in several layers.

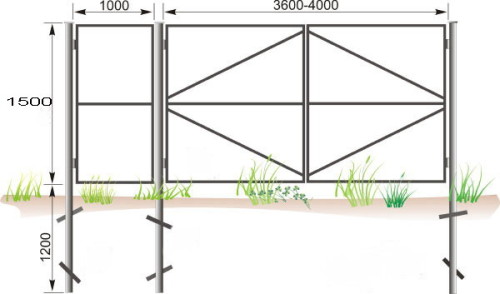

The pillar's sash support must serve as pillars. Their configuration depends on the weight and size of the sash. In the case of a sash frame from a profiled pipe, its weight will not be too high, therefore, the profile pipes are completely suitable for a cross section of 100mm x 100mm. The thickness of the pipe wall must be at least 4-5 mm to provide them with the necessary strength.

The length of the pillars depends on the height of the gate, taking into account the absorption of them on the magnitude of the primer of the soil. As a rule, depth 1.2 - 1.5 m should be enough. If the pillars are laid out of the brick, then for fastening the hinge of the leaflets in the masonry, metal inserts must be laid.

For the manufacture of sash gate of metal welds, a pipe with a cross section of 40 x 40 mm or 40 x 20 mm is used. It is cut into measuring pieces. At the ends of the pipes is made at an angle of 45 ° to connect them at right angles. Cutting works are carried out with the help of a grinder, followed by removing the champers to the smooth welding seam.

Welding work is carried out on a flat surface. The ideal option will be the presence of a welding table, however, for a single case, it makes no sense for a single case. For welding, a welding machine and electrodes Ø 4-5 mm are used. When welding the frame necessarily need to check the length of the diagonals. It should be the same with a maximum tolerance of up to 2 mm.

After welding the outer frame, you begin to cook the inner frame. In the middle of the frame, we screw the horizontal strut, sharing it into two parts. Then the pipe diagonally is screwed into each part. This design does not require a large number of materials, but it is quite strong.

When welding, it is necessary to pay attention to the quality of the seams. They should be hermetic. Otherwise, water can fall inside, which will cause the corrosion of the gate frame. After the end of the welding work, all seams are cleaned with a grinder with a credit circle.

The latter step is welded with a loop on the support poles and sash. The top of the loop is welded to the sash, the bottom - to the post. If the upper part is deaf - it is necessary to do a small hole for lubrication. To make the sash could be removed from the loops, limiters weld to the columns. When using a profile pipe for welding of the frame of the sash, a stand from a sheet metal is welded in the place of welding, to which the loop is boiled. This is done in order not to burn the electrode wall of the pipe.

After the completion of the work, the frame of the gate flaps is cleaned, soaked and painted. If professional flooring or a wooden plank will be used to cover the flaps, then the frame is painted before the skin. In the case of using the steel sheet, it is first welded to the frame, and then paint the entire structure.

Installation of sliding welded gates

When installing sliding welded gates, special attention should be paid to the guides for which they will move. Any skew in one of the parties can cause the mechanism to encamper, which will necessarily lead to its breakdown.

The design manufacture of the retractable gate sash is not different from the manufacture of sash sliding models. The only and main difference is to install the rollers at the top for suspended and downstairs for the support gate.

If the sash itself is not very different from the swollen, then the gate frame deserves separate attention. It must be two times wider than the sash. It consists of such a frame of 2-3 racks and crossbars on which the sash rollers will be suspended.

For a sliding gate at the bottom sets a special rail, along which the sash will roll back. This option is the easiest, however, in the cold season it is not quite practical.

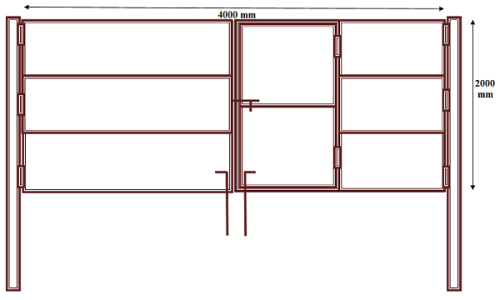

Welded gate with gate

This technique is quite common in cities where the site width does not allow you to install a separate gate and a gate. In this case, the latter is cut into a cloth of one of the sash. In principle, the manufacture of the wicket does not differ from the manufacture of the goal sash. The support post for it will serve the vertical stiffness of the sash. Since the weight of the wicket is not too high, it is no need to give it to the structural elements. The wicket frame is made of the same profile pipes as the gate frame.

The handle and the lock on the wicket are installed at the very end, after the gate is painted.