How to make floors on the ground in a private house do it yourself Insulation,Floors

The flooring device is soil with his own hands - the most affordable and simple technology of coating a draft surface. It is used almost everywhere. The exceptions are regions where constant and severe frosts prevail.

Content

How to make floors on the ground. Characteristics of the coating

In order to make the floor to the ground with their own hands, it is necessary to take into account a number of factors. The main ones are the features of the soil. For example, the level of groundwater occurrence should not be higher than 0.5 m from the surface. Only subject to this requirement will be missing and deformation changes in the soil.

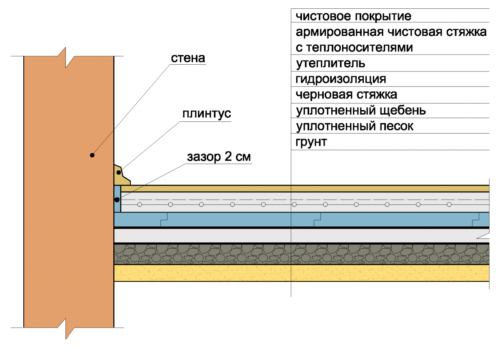

Special attention is paid to the choice of materials. In essence, the floor of the soil is a multi-layered design, to create river sand, crushed stone, waterproofing material, insulation, concrete solution, reinforcement grid.

The main purpose of rubble and sand is to prevent moisture from entering the room. Also, with the help of these materials, the surface is equalized. Do not use clay. This material absorbs moisture and can change its dimensions.

For surface waterproofing, it is possible to use a conventional polyethylene film. It is placed in two layers from below and on top of a draft floor screed along the soil made by their own hands.

In the insulation can perform various materials. The best of them are mineral wool, foam and penplex.

The steel grid for reinforcement makes the base of concrete as strong as possible. Also, it is also possible to fasten the pipes.

As a result of the qualitative conduct of all work, the floor is characterized by:

- lack of heat loss;

- good sound insulation;

- reliable protection against groundwater;

- unexpension of condensate.

When you create a concrete floor on the ground, an excellent protection of the coating from low temperatures is achieved. Moreover, such a floor can be triggered by any finish material, including coatings with maximum load.

Efficiency, simplicity and speed of installation work - the main trails of the floor on the ground made from concrete.

The process of the floor device itself consists of these steps:

- preparation of the foundation;

- waterproofing floor;

- reinforcement of the surface;

- concreting base;

- laying of thermal insulation material;

- creating a finishing screed.

Video about the tie of the floor on the soil do it yourself:

How to make floors on the ground. Preparation of the foundation

This stage suggests:

- determining the level of the position of the first floor;

- removal of excess soil;

- level alignment;

- watering water;

- thorough surface of the surface;

- creating a sandy pillow.

To create a sand pillow:

- the aligned base is covered with a 30-centimeter sand layer;

- sand is aligned (cords are used) and poured with water.

To resurmine the surface, you can use the rail to 2 m long, which is moved along the entire surface. In the implementation of this work, the sand is evenly distributed. The height difference should not be higher than 10 mm.

Sand backing is recommended to carry out layers up to 20 cm. Each layer is watering with water and tram. After that, crushed stone (or small gravel) is falling asleep with a layer of 10 cm, which is also tumped.

How to make floors on the ground. Poland waterproofing

The next stage according to the step-by-step instructions to create floors on the ground with their own hands is a device of reliable waterproofing.

As a waterproofing material apply:

- polyethylene film;

- special membranes;

- ruberoid.

It is advisable to use the polyethylene film in the presence of dry soil. In the case of waterproofing of wet soil, membrane and rolled materials are settled.

Stages of work:

- waterproofing is laid on a crushed stone with an overlap at 10-15 cm;

- the extreme part of the material is laid on the walls (20-25 cm);

- the jokes are sickling with scotch.

When performing waterproofing work, close attention is paid to laying the material at the corners of the room. It should fit tightly to the wall.

Reinforcement of the surface

This process is carried out to improve the strength indicators of a concrete base. To do this, you can use the wire or rods of fittings. But the best option is a metal mesh.

Installation of the mesh occurs on special stands 25 mm high. This is done so that the reinforcing mesh is located in the concrete layer. Only so you can achieve the maximum strength of the concrete.

Concreting base

To facilitate the Floor Filling Procedure on the ground with their own hands, you should install guide rails. Galvanized profiles can be made in their roles that are used to create a frame for plasterboard.

Base concreting provides for the following actions:

- conditional division of the room on equal sections with a width of up to 2 m;

- installation of guides on cement mortar;

- the upper part of the guides must coincide with the zero floor mark;

- the correct location of the guides in the vertical plane is controlled by the level;

- preparation of concrete mortar in small portions (1 hour cement, 3 hours of sand, 4 h. Gravel, water);

- pouring solution between guides.

Begins the process of concreting from a long corner from the entrance to the room. The pouring of the mixture occurs with the reserve. The excess solution is evenly distributed over the surface using the rule. Similarly filled all sections. After that, for 3-4 weeks, the frozen concrete is wetted with water and is covered with a polyethylene film.

Floor insulation and finishing screed

After drying the rough screed floor, the floor must be inspired. To create with your own hands of a warm floor on the ground it is better to use the penplex.

Stages of work:

- on a concrete surface, a vapor insulation membrane is filling;

- out of the membrane laid the plates of the fastener (for reliable fixation of the material, you can use fasteners or glue);

- the joints of the heat-insulating material are glued with scotch;

- the insulation is covered with waterproofing material.

The device of the finishing screed of the floor on the ground with their own hands is carried out similarly to the base concreting process. The only nuance is that at this stage, the commissioning of communications should be provided with a subsequent device of warm water or electric floor.

Video on the floor of the floor on the soil do it yourself: