Bath furnace with your own hands Baths, saunas and pools

The furnace is the main attribute of any bath. The heating rate, fuel consumption, the amount of smoke and carbon monoxide emissions to the room depends on its quality. Therefore, the installation of the furnace should occur in accordance with all the rules and rules of which and talk.

Content

Highlights that need to know before installing the baths for the bath

Like any other furnace, a bantal firebox consists of four key points:

- fuel combustion tanks

- chimney

- heat supply systems

- foundation.

Often, the fireboxes are made of cast iron, but there are more modern metal options. Comparing these materials, the experts concluded that the classic cast iron base suits better:

- longer gives warmth,

- more durable

- not deformed at high temperatures

- suitable for any type of firewood,

- much more durable.

Chimney provides a craving from which such an important indicator depends as the power of the furnace. The better the air exchange, the faster the fuel is roasted. In addition, a good traction allows wood and coal to get root completely, which significantly reduces consumption.

In a classic bath oven, the heat supply system is reduced to the fact that the tops are poured on top of the furnace, which after heating begin to give heat. Nevertheless, it is not entirely convenient to keep the hotbed directly in the steam room. Therefore, more advanced technologies are used when the furnace itself is installed either outside the bath or in the pre-banner.

The right foundation for the furnace is very important. From the reliability of the base on which the furnace is located, its operation depends, which ranges from several months to 50-60 years.

Although not the key, but the principal moment is a visual design. The furnace itself looks fairly simple, therefore it is refined either by a stone or heat-resistant fireplace tiles. Another thing that will not be superfluous is a hot water tank. We will then consider in detail how to make a bath for a bath, give her functionality and an attractive appearance.

Bath Fuel Fuel

The process of creating a bantle furnace begins with the choice of fuel. In practice, the following varieties are found:

- firewood,

- coal,

- gas,

- kerosene.

Firewood is the most common option. With a relatively small flow rate, raw materials allows you to quickly warm the room and long maintain the necessary temperature in it. Nevertheless, periodically need to go and throw up the firewood. Especially if the steamer is big. Fires for baths on firewood are made of cast iron. Although metal analogues are presented on the market, in practice they are used extremely rarely.

Tree burning temperature from 400 0From up to 1200. 0C, despite the fact that the steel begins to melt at a temperature of 800 0With -1000 0C, the application of these furnaces is inappropriate.

Coal has all the advantages of the tree, but you need to throw it much less often. The problem of coal in its high cost and the need to install powerful, specialized boilers designed specifically under coal.

Gas allows you to create an autonomous heating system. In addition, the gas combustion temperature is only 300 0C -400 0With, therefore, it is possible to establish a cheaper metal furnace, and if you wish and the presence of a welding machine - make it yourself. The gas has only one significant disadvantage - the room is heated for a long time. For baths with a volume of more than 20 m 3 The use of gas is generally ineffective.

Earlier, kerosene nozzles were used quite often. First of all, it was associated with extremely cheap price. Now the situation has changed, so the use of kerosene has lost relevance.

Bath Fixtures

By an embodiment, all the furnaces are divided into:

- bath Fire

- fire across the wall.

By the method of registration on:

- bulk,

- grid type.

The firebox from the bath suggests that the furnace housing is monolithic. It consists of:

- furnaces

- swirl

- chimney

- capacities for stones.

The first two elements to make your own is difficult, therefore, if there is no old cast iron boiler, have a long mess.

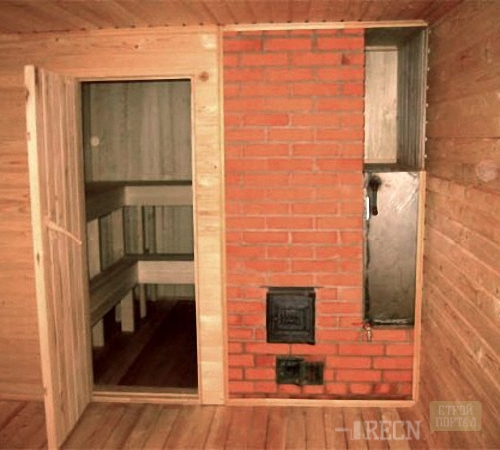

The furnace bath Street possible with a somewhat different design. When the fuel container is connected to the main boiler with special transition. Its length is 10 to 30 cm. In larger length is lost too much heat. As a rule, the furnace bath from the changing room in the selection of this option. First, it allows you to not go out in cold weather outside, and secondly, makes it possible to accurately decorate ugly part of the furnace.

The bulk models, installed on the furnace tray which is filled with stones. In the grid, the grid for the stones mounted around the perimeter of the boiler. Its use increases the area to fit the stone oven, as a consequence, the room warms up quickly. Embodiments of the grid are many, from the use of metallic streamers on old beds up beautifully designed wrought fence.

Factory iron furnace for a bath equipped with heat-resistant glass, which turns it into a sort of fireplace. Sweating in the bath and watch how fire burns quite nice. Especially considering the fact that the door fits tightly and combustion products do not fall into the room. But, when it comes to self-cook the furnace, it is better to stay on the grid option through the wall.

Methods of making the furnace for the bath

Options on how to make the furnace for a bath, quite a lot. To work, you will need:

- welding machine,

- gloves,

- electrodes,

- bulgarian.

For the hull will need at least 2 mm thick steel sheet. If there is an iron barrel, it is also suitable, but with the additional reinforcement.

assembly steps:

- Cut the sheet into seven plates - 60 cm long, 30 wide.

- Six sheets welded together.

- To the rear wall, which without additional reinforcement, the two side weld.

- Cut the upper part of the furnace - two sheets of 30x30 cm. To weld them together.

- Weld the roof at a height of 40 cm. The remaining 20 cm will be used as a container for stacking stones.

These points need to be made as to the furnace in the steam room, as well as to the furnace through the wall. Further, the procedure is different.

The furnace in the steam room:

- In the front part by means of grinder to saw a flat square for stacking fuel, the lower edge at a height of 15 cm in Size -. 10x10 cm.

- To saw from a sheet of 15x15 cm square. As one of the cut sides of 4.5 cm, this edge will be turned to the loops.

- Spear from one of the sides of the loop.

- Cook a sheet of 10x10 cm and 15x15 cm so that around the leaf 10x10 cm turned out to be a proact of 5 cm and 0.5 cm near the loop.

- Swelling to the cover of the furnace of the cover of the loops and put it on the loop, check the course.

- Remove the lid, and at a height of 5 cm make a slot 4 cm wide and a long 10 cm.

- Cut off the sheet of a strip of 5 cm wide and a long 12 cm.

- In the middle of the strips for 2 cm from the edge, to weld the rod of reinforcement with a diameter of 1 cm or 2 cm and a long 6-7 cm.

- Cut from the sheet two squares of 30x30 cm. From one of the edges, which will look at the rear wall, cut off 10 cm.

- Cook the sheets with each other and weld to the front wall at a height of 30 cm.

- Next, the facial wall is welded to the rest of the case.

- The swirl is welded to the side walls.

- Three squares of 30x30 cm are cut out of the sheet and welded with each other.

- The bottom is welded to the body.

- Final strokes - insert the damper pushed, strip with welded reinforcement, and put the door.

In order for the damper not falling inside, it is advisable to make a guide. For this, it is sufficient to the length of the slot on top and bottom to pride the reinforcement so that the distance from it to the handle was attended by several mm. To hardly bother, it is enough to wind the handle with the wire.

Now consider this design. In its parameters, it fully complies with the factory models. In quality, it all depends on what the welding machine is performed. If the seam is reliable and smooth, the boiler will last up to 50 years. Special attention should be paid to the swirl. This element allows you to effectively separate the open fire from the combustion products. The disadvantage of the design should be called uncomfortable cleaning of the furnace. Sometimes they make a similar model with a retractable bottom. But, such a bottom is fire hazardous, since at home it is impossible to protect all the gaps from open fire. Consequently, the risk of fire rises at times.

After the firebox is cooked, you need to still equip the chimney:

- in the roof of the furnace, near the edge, located closer to the wall, on an equidistant from the side walls of the distance, the square 4x4 cm is cut,

- next, it is necessary to prepare a metal tube with a diameter of 5 cm,

- if the model is supposed to be the manufacture of water without a water heating, the pipe is 20 cm, if with a tank - 150 cm,

- further, the pipe is welded to the roof of the furnace and the withdrawal of the chimney is ready.

Production of additional elements of the firebox for a bath

Above it was considered in detail the scheme of the creation of a furnace located directly in the steam room. If there is a need to equip the furnace in the pre-banker, you will need to hold a certain modernization of the structure:

- the first thing is welded metal frame,

- it will take 12 sheets, 8 with dimensions - 20x60 cm, and 4 - 20x20 cm,

- sheets are welded among themselves, after which the metal box is done,

- the roof is welded at a height of 40 cm from the bottom,

- chimney is welded to it,

- in the front part, an opening of 15x15 cm is cut, at a height of 10 cm from the bottom,

- next is going directly to the furnace,

- since in this design, neither the swirl nor the tray for stones is needed, the dimensions of the furnace 30x30 cm,

- it should be added that in this design, the rear wall is made of paired sheets,

- after the furnace is ready, in the rear wall, drink a hole 15x15 cm, at an altitude of 10 cm from the bottom,

- two boxing are combined with interconnected metal sheets, which are welded to the furnace,

- their width is 15 cm, and the length is determined depending on the walls and the specific features of the object.

It is often common for the fact that there is no sense to make such a difficult work, since it is much easier to use the usual steel barrel. In practice, the boiler made in this way, firstly, quickly procee, secondly, will quickly warm the room, thirdly, it will require significantly more fuel, as it is not possible to significantly reduce the sizes of the barrel.

Another useful thing is a pot with hot water. It is advisable to use the chimney pipe as the heating element. At an altitude of up to 1 m, it is able to maintain water temperature 60-100 0WITH.

There are many tank arrangement methods:

- old casserole of large diameter,

- iron bar,

- bidon,

- welding

- car rim from wheels.

If finished utensils are used, it should be somewhat modernized - to prigerate a piece of metal. It is done that in the process of welding do not speculate the thin bottom of the pan and barrels.

In order to secure the tank with water on the chimney pipe, the hole is cut into the diameter of the pipe and the row is dressed on the chimney, then the bottom is welded to the pipe. In this case, it is desirable to provide additional support for the container to reduce the load on the pipe. The final stage is to weld or fasten the faucet on fittings.

If there is a desire to make the original Chan for water, then recommend using rim from the wheels. Two rim will need for work. At the beginning, all openings be brewing except Niza and top. Then the rim is welded with each other. A metal base is welded to the bottom, the hole is cut into it and by analogy with the rest of the way, fasten on the chimney.

Of the advantages of such a tank - only the original appearance, in the rest, it does not differ from other options.