How to make a steam room - do it yourself Baths, saunas and pools

Paired - Bathroom base. The mood of the owners and their guests depends on the quality of its manufacture, as well as the safety of those who are batted.

Content

Parik? Not a problem!

All pair work starts from the project. Make several project options. So you can calculate all the required costs, as well as determine the ability to install the desired technique. By selecting an acceptable option, consider the stage of work, in order not to encounter the alteration of surfaces and structures.

When preparing the project, it should be repeated from its center - the furnace. Each furnace places its requirements for the size of the room, the presence or absence of ventilation, the location of the shelves.

The size of the steam rooms are determined on the basis of the number of people who will be at the same time in the pair. Today, the following dimensions are considered to be the standard: Length 2.4 m, width 2 m, height 2.2 m.

Lighting in steam room

If there is a desire, then of course you can install in a pair window, just why? For lighting, there is enough ordinary lamp. It must be installed in a special ceiling. Wires and all other components of wiring, and the connecting elements are carefully insulated. Wet air can output lighting devices if there are damaged areas on a wire or "cartridge". A more reliable option is to pave the wire in a special box under the layers of waterproofing and vapor barrier on the wall.

The window in the bath, even the smallest, creates a place of heat leakage and as a result - requires thermal insulation. But still, if the desire is insurmountable, then it must be extremely small, for example, at a height of no more than two crowns, and in length no more than 500 mm. The ideal solution will be in this case the installation of the glass package.

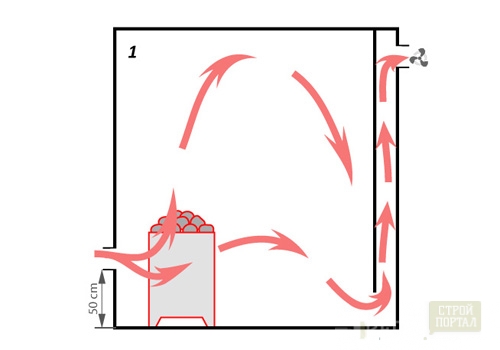

Installation of ventilation in steam room

The task of ventilation in the pair - ensuring a healthy climate. The fact is that the wet, warmed tree is almost a farm for reproducing fungus, mold and other not very useful microorganisms. To solve ventilation, it is advisable to apply the exhaust ventilation system.

Exhaust ventilation system displays extra humid air from the room, preventing the formation of condensate on the walls. When you choose ventilation, pay attention to its power.

If you doubt the correctness of calculating the power of the exhaust system, contact the firm that is engaged in installing exhaust systems. A specialist will arrive from the company, will make all the necessary measurements, it will ensure the equipment itself and establish it.

If you decide to do everything yourself, then you need:

- Select and buy ventilation.

- Cut a hole in the wall corresponding to the diameter of the exhaust system.

- Insert the fan into the hole and fasten it.

- Simple and sharpen irregularities between the fan and the wall.

Interior decoration

The steam finish is carried out in the following sequence:

- Ceiling.

- Walls.

- Floor.

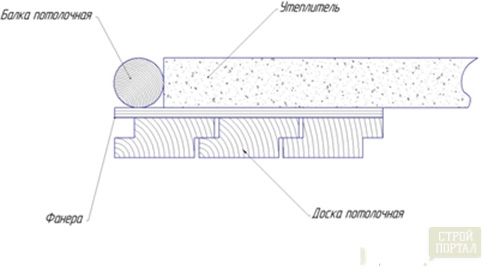

To prevent heat leaks through the ceiling, multi-layer insulation is used, see Figure 1.

As can be seen from the attached pattern, the technology is as follows: the plywood sheet is fixed to the ceiling beam, this is done in order to completely close the ceiling. Already then the boards are attached to it, they can be with a sample or tipped. It is advisable to leave a gap between them. A leaf of the insulation is stacked on the fane from above. Some builders offer to use the so-called foil, that is, covered with foil layer.

Wall insulation

Warming is used to preserve heat inside the steam, without giving it to "disappear" through the walls, ceiling or floor.

Stages of work:

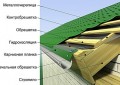

- The insulation (rolled or matte mineral wool) is placed on the wall.

- The previous layer is a foil. Used as a barrier layer of thermal insulation.

- Completes "Pie" vaporizolation.

All joints are necessarily processed with a tape with aluminum coating.

Parligh sheathing

The walls in the steam room are triggered, but only after the shelves are collected and installed. The material of the lining can provide a useful and unforgettable smell if it is made of coniferous rocks (pine, spruce). Resintees can not be avoided, but you can reduce their manifestation if you drive a bath several times and remove the "streams".

Deciduous trees are also suitable for lining (linden, cedar, etc.) they also have essential oils useful for inhalations.

Using a wood lining with essential oils, you will provide yourself with a healing "corner". Be sure that such a pair will save you and your family from respiratory diseases.

Also, the lining will provide higher vaporizolation and tightness if it is made of hardwood.

For the trim, it is best to apply the molding of the maximum allowable thickness, it will increase the playproof and help avoid cracking the board.

The lining is fastened by the "PAZ in PAZ" locks system, and also for reliability is screwed by self-draws.

Shelves

The main demand for the shelves in the steam room is the absence of a resin on its surface, and it should not leave traces of sweat. From wood, which grows in Russia for these purposes, aspen is optimally suitable for its qualities, according to ease of processing, and at a price.

Constructively, the shelves are advisable to fix the wall, the volume of the room is so significant. If the pair turned out to be small, it makes sense to fix the shelves by analogy with shelves in railway cars, that is, to make them folding.

Bake

The furnace selection is a responsible event, each type has its advantages. Thus, metal furnaces are quickly heated and cooled, and everything else, the risk of getting a burn, if you are inappropriate to touch it. The furnaces folded from the brick are warm up and keep warm longer. They require a separate serious foundation. And metal and brick ovens combine one detail - exhaust pipe.

In addition to traditional furnaces on the market, electric furnaces are actively advanced, they do not need exhaust pipe, they can easily be configured to the desired modes, but it entails the adoption of additional security measures for the electrical part and it should be noted that the installation is made by experts.

NOTE: The market is growing for talco chlorite furnaces. The use of this stone allows you to produce a uniform heating of the steam and getting soft, pleasant heat.

Traditionally, the furnace is installed in the corner, near the door.

Door

The door in the steam room is the main reason for heat leakage, but the ways to eliminate this trouble are simple:

- The threshold is high to 30 cm from the floor level.

- The ceiling is lowered.

- From the outdoor side of the door sash, linings are fixed, protruding for the perimeter of the door at a distance of 20-40 mm.

After all, the main task of the door, skipping a person inside the pair - do not give warmth to go to the pre-banker.

The door is trimmed with insulating material from the inside and outside, followed by the clapboard. Alternatively, there are special bath doors made of heat-resistant glass. This is an interesting and beautiful solution, but quite expensive, not quite traditional for our pair.

Actually, the entire procedure for arranging the parillas is presented and, if you withstand recommendations, listen to the advice of those people who have already done the Parile with their own hands, take into account their advantages and disadvantages, then you can say for sure - your pair will be the best.

New comments

Add a comment

To send a comment you need authorize.

How long have Cedar become a deciduous tree?!