Foundation under the shed do it yourself Construction

The type of base for the shed is chosen depending on the material from which the walls will be erected. The foundation for a barrier from the brick should withstand heavy loads than for a wooden structure. Decide on the purpose of the commercial, as well as the base type is recommended before the construction. It is important to take into account the features of the soil.

Content

- Types of foundations under the shed

- Choosing the type of foundation depending on the characteristics of the soil

- Screw basement device

- Stamp Foundation under the shed

- Ribbon foundation under the shed

- How to make a foundation for a barn from blocks

- How to pour the foundation under the barn: the construction of monolithic base

- Concrete Solution Quality Requirements

Types of foundations under the shed

For the shed, you can use the following types of foundations.

- Columnar. The advantage of such a foundation in the economy of building material and the erection rate. Suitable for light frame-shield structures.

- Screw. Such a foundation is indispensable for construction on bunny, swampy soils and in the sand. Works on the device of such a base can be carried out at any time of the year.

- Slab. Also used on swampy or bulk soils.

- Tape: perfect foundation for a brick barn, a structure of stone or concrete blocks.

- Foundation under the barn from blocks. Combines some advantages of the foundations of other species. For construction it is necessary to use a lifting technique.

Choosing the type of foundation depending on the characteristics of the soil

The maintenance of the soil should be ordered in an organization specializing in services in the field of geology, geodesy and cartography. Depending on what kind of soil in the area of \u200b\u200bthe planned construction, certain problems may occur.

- Bulk, sandy ground. After the melting of snow or abundant precipitation, drinking moisture, he can "swim". For construction on such a soil, the device of a slab, screw or monolithic belt base is recommended.

- Clay soils and saths: such soil is inclined to deep freezing and forming floats. In this case, the screw piles should be used.

- The gravel soil does not freeze at a greater depth and does not form floats. You can build a barn on such a soil on the foundation column.

- Rock soil: It is possible to build any (except screw) foundation.

Screw basement device

The screw foundation for the barn can be built within one day. The piles with a diameter of 80-90 mm in the desired quantity and one helper. The procedure for the construction of the following.

- On the perimeter of the walls, markup is performed for screw piles.

- At a distance of 1.5-2.0 m, not deep holes are digging from each other in which piles are installed. This is necessarily performed in the corners, and in the presence of internal partitions - along the line of their erection. In addition, if the installation of the board is provided, the piles must be under the bars of the lag.

- Screwing the piles of a large size (with a diameter of over 100 mm, more than 150 mm long) is performed using special equipment. Piles are smuggle in the ground manually, with the help of levers. At the same time, it is necessary to control the strict vertical position according to temporarily attached waterpasses.

- The piles screwed into the soil are cut in height, for which the water level is used.

- Fill pipes with concrete mortar.

- To the top of the piles welded the gloves. In a single design, the foundation is combined with a chapeller or heated beam welded around the perimeter.

Important: The blades of screw piles must fit the type of soil. For loose sandy soils - wide, for dense soil - narrow.

The video shows how the screw piles are mounted in winter

Stamp Foundation under the shed

The construction of a column foundation for a household building can be performed using:

- concrete solution poured into the formwork;

- metal or asbestos-cement pipes, reinforced and filled with concrete;

- brick laying (used red ceramic bricks);

- boot;

- concrete blocks.

General rules for construction are as follows.

- To install the supports of the wells of the necessary depths in accordance with the previously performed markup.

- The distance between the supports should be within 1.5-2.0 m.

- The depth of the foundation under the barn should be at least 150 mm below the level of the fruit of the soil.

- At the bottom of the holes, the layer of crushed stone of a large fraction (about 100 mm) and the same layer of sand are poured. Both beds are sealing, on top of laid two layers of rubberoid.

- Supports must be installed at one level and tower over the surface of the Earth by 150-200 mm.

- On top of the supports also lay two layers of waterproofing material.

- A scene must be arranged around the posts: it will prevent the soil flushing.

Important: The construction of the barn should be continued immediately after the construction of the foundation. Otherwise, spring beaming can partially squeeze the poles.

Wooden foundation under the barn can be used as an option of a base device for a temporary building. To do this, it is necessary to harvest the required number of bars or logs from solid wood. Piles are burned to the state of charred or treated with an antiseptic.

It is recommended that it is recommended to wrap each whole support with a polyethylene film or runner: it will protect the wood from moisture and prevents the pillars of the pillars in the spring of the soil. For greater reliability, the pit around the support is recommended to fill in concrete.

For the shed, you can use the combined type of foundation - columnar with painter. The technology of its creation provides for the fill of the fine-breeding belt basement (0.7-0.8 m) with recesses for supports located in the corners and every 2.0 m.

Ribbon foundation under the shed

Such a base is the most popular for several reasons:

- its construction is relatively cheap;

- able to withstand significant loads;

- it is universal: on this foundation it is possible to build a barn of any material.

Phased ribbon foundation under the shed with their own hands is constructed as follows.

- Plot is prepared (the turf is removed, the playground is aligned) and markup is performed. With the help of stakes and the kapron cord, limit the perimeter of the future foundation.

- In the perimeter, the barn rose trench, the depth of which should be 200-300 mm below the level of soil freezing in this area.

- The width of the trench depends on the width of the base: it is necessary to leave a place to set the formwork (100-150 mm on each side).

- A pillow of rubble is made (about 100 mm), which should be carefully tumped.

- On the bottom of the trench, sand (50-100 mm), which is also tamped.

- A formwork is knocked out of the boards or sheets of plywood, the top edge of which should be higher by 200-300 mm relative to the ground level.

- The formwork is strengthened with pins, the upper edge is shot down by transverse bars every 1.5-2.0 m.

- Ruberoid or thick (at least 50 μm) polyethylene is recommended for the inner walls of the formwork.

- Reinforcement with steel rods with a diameter of 8-12 mm. The elements of the reinforcement are stacked and associated in such a way that a volumetric grid with cells 40-50 mm is formed.

- The fill with concrete is performed. To drive the air bubbles, the concrete must be repeatedly pierced by a rod of reinforcement throughout the perimeter of the fill.

- The frozen concrete should be covered with polyethylene film and periodically wet. This will prevent his cracking due to uneven frosted.

- After 28 days, after a complete secretion of concrete, the formwork can be dismantled and perform the inverse swelling of the trench with the soil.

- On top of the concrete fill, two layers of waterproofing material are stacked.

How to make a foundation for a barn from blocks

The foundation from concrete blocks in its strength characteristics is no inferior to the tape base. The construction process consists of several stages.

- A plot is prepared, markup is performed, the trench of the required depth is broken. The bottom should be aligned horizontally and tamper.

- A bed of sand and gravel is satisfied.

- Using load-lifting equipment, blocks are installed in the trench. The side sides are applied cement-sandy solution.

- Each subsequent number of blocks is stacked with a displacement of half the length relative to the previous one. A cement-sandy solution is applied between the rows. Above the surface of the earth must be laid at least one series of blocks.

- Bituminous mastic is applied to the side and upper sides with the help of a car.

- The inverse swelling of the trench is soil.

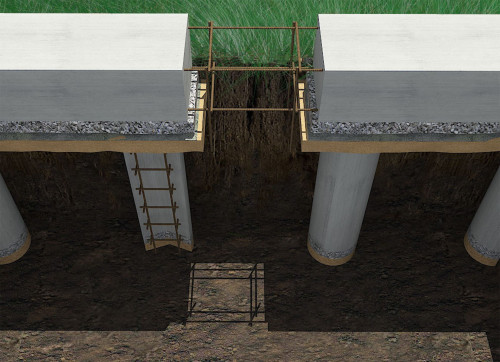

How to pour the foundation under the barn: the construction of monolithic base

The monolithic or slab base is the most reliable. You can build on such a foundation on a soil of any type. The construction of such a foundation is the event cost, but if the construction of a massive cozpostroy is assumed in difficult conditions - expenses will be justified.

Technology of the construction of a slab base involves a specific sequence of actions.

- The construction area is cleaned by garbage, bushes and trees.

- Under the entire area of \u200b\u200bfillings, a hole is deep in a depth of 0.5 m. On the bottom, after the trimmer, the sand layer is poured with a thickness of 200 mm. The sand moisturizes and thoroughly tram.

- On top of the sand laid a 200 mm layer of rubble, which also tram.

- On the pillow of sand and rubble laid the slabs of the overlap or prepared to the fill. To do this, formwork is constructed, reinforcement: the grid cell must be 20 × 20 mm. The formwork is poured concrete.

- Air from the solution must be expelled using vibropress.

- The non-frozen solution is covered with a polyethylene film.

- Formwork can be dismantled after 28 days (during this time the solution will clarify, concrete will type strength).

Important: The stove should rise above the surface of the soil by 100-150 mm.

Concrete Solution Quality Requirements

In order for the concrete foundation to withstand all loads, it is necessary to pay due attention to the quality of all components of the solution. The following rules must be followed.

- It is recommended to acquire cement with a fresh manufacturing date. For cooking you can use Portland cement M400.

- In order to save cement, the crushed stone of different fractions should be acquired: it will be better, it is more detailed to fit in solution.

- It is important that the crushed stone is clean, without garbage.

- Water should be used purified, since impurities make the solution weaker.

- Sand should not contain the inclusion of clay.

- When preparing a solution, the proportions of the components should be observed: 5 parts of the crushed stone are added to 3 parts of the sand, and then 1 part of the cement. After stirring, water is added in such a quantity so that the consistency of the resulting mass is sour cream.

In conclusion, the story about how to build a foundation for a barn, video with a specialist comments. This information will help avoid errors.