Installation of pipes in the bathroom and toilet do it yourself Plumbing

No overhaul of the bathroom and toilet do not cost without replacing old communications: sewage, water supply and heating. Moreover, often new pipes are not put on the place of old, but develop another, more convenient layout scheme. How to carry out communication to improve the ergonomics of the useful space and the installation of pipes with your own hands we will talk in this article.

Content

Choosing pipes

Even the most durable and reliable communications sooner or later fail, so you have to think about their replacement. But to begin with, it will be nice to learn about the varieties of pipes available in the modern market to know what to work with. Previously, the choice was small and mainly boiled down to the cast iron or metal. Today it is much better.

Types of bathroom and toilet tubes:

- Metal - copper or steel products. May be solid, welded, threaded, without threads, coated with anti-corrosion composition or unprotected. Often are sold complete with fittings - special connecting details.

- Cast iron - the legacy of the last century, today used for the most part for the installation of external sewer systems. Pretty durable and durable products, but unprotected from corrosion.

- Asbestos-cement - lightweight pipes that are immunity to the effects of dissolved substances dissolved in water. It is easy to work with them, so they are used not only for installation of sewage, but also to arrange exhaust systems. There are such products inexpensively, but they differ in fragility. In addition, they allow you to create only direct portions of the pipeline.

- Plastic - the lightest and easy-to-install products. They are distinguished by low weight and increased bandwidth (smooth inner surface does not delay solid particles in water). Do not rust, allow you to lay compound highways in a close space. The disadvantages include instability to temperature drops.

- Ceramic is an excellent alternative to cast-iron products, and therefore often used for the installation of external sewage. Do not pass water, resistant to chemical and temperature drops due to the durable glazed coating on both sides.

- Metal plastic is one of the latest innovations in this market segment. They are a plastic base covered by a layer of corrosion resistant and metal chemicals. This design weighs little, copes with temperature differences (unlike purely plastic pipes) and easy to handle. With the installation of metal-plastic pipes, any inexperienced master will cope with your own hands.

The choice of pipe diameter depends on their operational load. For example, for a trunk riser, a large diameter product should be given to about 110 mm, a 40 mm diameter is suitable for internal riser. For water pipes (hot and cold water), you can use pipes with a diameter of 15-20 mm. For water drain system - 60 mm.

Useful advice: Experts recommend choosing metal-plastic pipes for hot water, and for cold - inexpensive plastic or durable copper. You can also buy steel pipes with protective zinc coating.

If you are planning to install polypropylene pipes with your own hands, in this case you can do without welding. This option is the most popular among home masters, but we will talk about it in more detail a little later. In second place after polypropylene pipes are metal-plastic. They also easily cope with the newcomer, and the service life of such communications is calculated by decades. In addition, the high bandwidth of smooth pipes will prevent the occurrence of blockages.

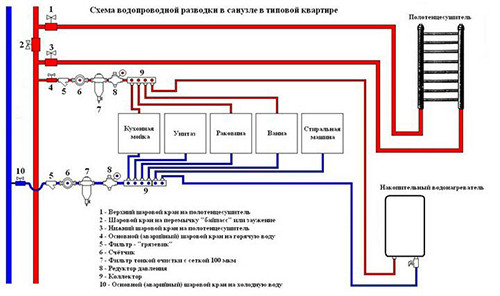

Before you go to the store for pipes, you need to calculate how much they need them for your bathroom. The optimal option will be the compilation of the detailed scheme of the location of all communications, the designation of the distribution points and all strategically important plumbing devices (washing machine, sink, toilet, shower).

Methods of installation

To get a comfortable and cozy room, before being repaired, it is necessary to create a detailed plan of its actions. In our case, this is to make the pipe layout scheme so that it is in a solid system. All parts must be interconnected. If possible, it is better to organize their position so that they are not only functional, but also autonomous.

At first, it is necessary to develop a clear scheme for the location of the plumbing, to which the pipeline will go. If there is a separate bathroom in your apartment, then the wiring must be carried out in the complex with the bathroom, and not separately. But before you know about all the features of the work, we suggest you to see a useful video about how you do not need to make a wiring. It will help you avoid the most common mistakes.

During the work, apply chalk markup on the route of all pipes, their size and connection location with other elements. Then you can decide how to implement all this in practice. To do this, you can use one of the ways to install sewer pipes with your own hands: hidden or open. Here everything works on the same principle as with electrical wiring. Open method involves gasket on the surface, hidden - in the wall, where the special groove is pre-latter.

If you decide on an open way, you should immediately warn that aesthetics in such a solution will be little. Even if the pipes will go from the floor or under the ceiling, where they are least noticeable, from time to time they should be wiped from dust and dirt. In order not to harm the interior of the room, it is better to make a hidden gasket, hiding all the communications in the wall structures. Another thing is that the work will take away much more time and strength - the session of the wall is not a lung.

Useful advice: As an alternative option, it is possible to use drywall - pave pipes outside along the walls, and then hide their drywall screens. Of course, it is suitable only for spacious premises, where you can sacrifice several dozen centimeters of the square without much regret. To do this, first build a frame of metal rack profiles, and then they are squeezed with moisture-resistant plasterboard and coated with a finishing material. Useful information on this topic can be found in articles "Frame from the profile for plasterboard: installation features" and "Tile on plasterboard in the bathroom: laying features".

When you were determined with the way of installation, you should figure out how to physically lay pipes. This can be done in several ways:

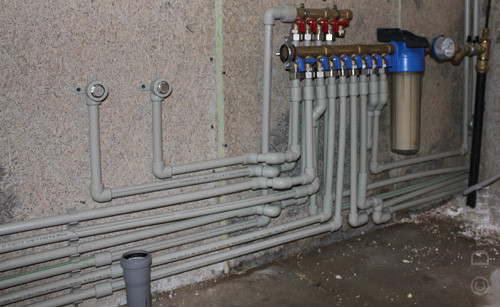

- Sequentially - such a layout is very simple and understandable. The pipeline highway is stacked step by step, methodically connecting one device to another. If you look from the point of view of installation, then everything is just fine. However, this method has one significant drawback - water pressure during the operation of the system is unevenly distributed if several plumbing devices are included.

- Coloring - For such a layout, it is necessary to install a crane for each pipe, which is summarized to the plumbing device. In such a simple way, in case of a malfunction, one of them can simply block the corresponding crane, instead of turning off the water in the entire apartment or riser. In fact, you will make an individual pipeline segment for each of the devices. However, it is necessary to immediately warn plumbing newcomers - such work may be too difficult in performance, but with a strong desire and patience you can cope with it. In addition, as you understand, the consumption of materials will be much more than with a sequential layout.

- With passing outlets - this method is very rarely used in everyday life, since in itself is complicated. Such work is better to entrust professionals and take advantage of one of the two methods above.

Whatever the installation of plastic (or other) pipes you choose with your own hands, for the successful outcome of the case, you must comply with several conditions. First, try to make as little connective nodes and bends as possible, while retaining the integrity of the pipes. Each of such compounds is a potential leakage site, and every bent knee is the place of formation of a blockage. Secondly, allow windband of cold and hot water pipes only if it does not work in any other way. Thirdly, all the highways should be organized in such a way that the result is a complete and concise composition, and in the event of a breakdown, it was possible to easily get to any site.

Working with polypropylene tubes

We decided to consider the features of the installation of heating and water supply from polypropylene pipes with their own hands in more detail, since it is most often most often appeared in the work of domestic and professional masters. If you decide to an independent replacement of old cast iron highways, it is best to choose polypropylene products. They have a lot of advantages, but the main advantage is the fact that already after 30 minutes. After welding, you can fully use the entire system.

Below on video - the choice and installation of polypropylene pipes of heating with their own hands:

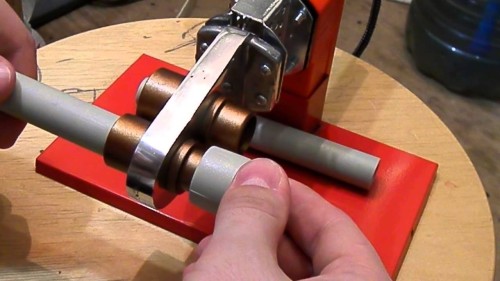

Technology welding

To connect to 63 mm with a diameter with a diameter of up to 63 mm, the wizards use fuse-free or coupling welding. In the first case, the end of one pipe enters the end of another, wider. Coupling welding involves the use of a special connecting part - couplings. The ends of the pipes have the same diameter, they are created in the coupling and weld. If the pipes are connected using a thread, for this use fittings with sockets.

If you have to work with polypropylene tubes, the diameter of which exceeds 63 mm, it is necessary to use the technology of welding technology. It does not need any couplings for it, while the connection is distinguished by reliability and durability. In the event that you still found fittings suitable for this occasion, no one forbids consolidating the effect of coupling welding.

For mounting pipes of heating with your own hands, you will need a welding machine properly. A simple manual model can be used for pipes up to 40 mm in diameter, and for more widely need a professional stationary mechanism capable of conducting a center. The heating element uses a sleeve (a removable part with a teflon coating that does not allow the melted material to adhere to the heating element). It quickly melts the polymer surface of the pipe, thereby creating suitable conditions for mutual diffusion of the molecules of both parts. From this we can conclude that the work passing at the molecular level gives a homogeneous seamless connection. Not only the external, but also the inner side of the termination should be heated.

Useful advice: despite the presence of such a useful thing as a Teflon sleeve, you still need to follow the cleanliness of the working surfaces and, if necessary, to consider the remnants of polypropylene. To do this, you can use the usual dry rag or wooden blade. It is important to have to consider "Nagar" until the polymer is completely frozen.

If you work with pipes with a diameter of more than 40 mm, and therefore - with a stationary device, it must be installed on a flat surface so that it does not swing during the work process. Before you enable devices, select and install suitable nozzles. If the bathroom is too close, and to solder is inconvenient, it is best to enlist the support of the assistant.

Mounting Rules:

- To cut the pipe, use acutely compatible knife or high-quality metal scissors. The incision must go strictly at an angle of 90 °.

- If you use reinforced pipes, remove the metal shell from the ends before soldering.

- Be sure to put the gloves before work, otherwise you risk getting serious burns.

- To get a durable connection, nozzles need to warm up to 260 °. However, wary of their overheating, otherwise the polypropylene structure collapses, and the pipe can be cleaned.

- Working with fittings, weld them as quickly as possible, following the disks. Seam should be even and uniform.

- After completing the soldering, make sure that the connected elements remain fixed relative to each other at least for 2-3 minutes. Until the seam finally clarifies.

Below on video - Installation of polypropylene pipes with your own hands:

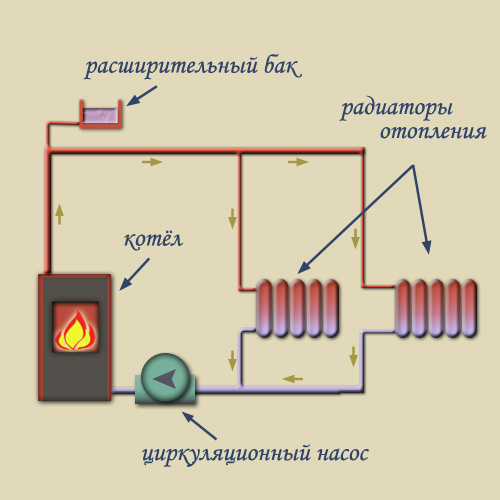

Pipes heating

Since the polymer pipes are not so tough as metal, they need to be attached to the wall every 40-50 cm. It is best to use them only for internal wiring. Usually, any heating system consists of a heating device, heat transfer elements (batteries), a pipeline by which water goes from the boiler to batteries and back, expansion tank and fasteners. The tank is necessary in order for water to damage the system when it increases in the amount due to heating.

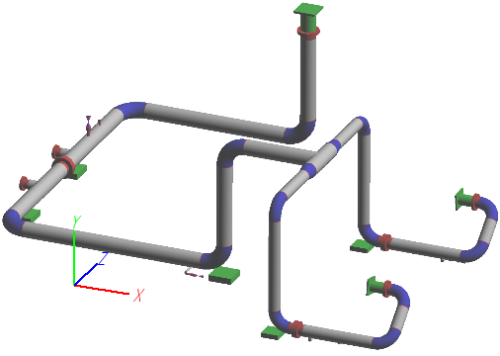

To install the boiler, it is better to choose a separate room if it comes to the bathroom in a private house. If work happens in the apartment, the boiler can be put in the hallway, in the kitchen or in the bathroom itself, if it is spacious. The prerequisite for the operation of the boiler is the presence of an exhaust indoor. Plan your heating system so that the return pipe is located at one level or above the receiving input of the boiler. If it goes below, the circulation of water will be very weak or will disappear. Especially for this, professionals make up a three-dimensional diagram of the entire pipeline, where they indicate the location of radiators, all turns and places of wall passage. You can do this in a computer program, but it will require appropriate skills to work with it.

According to the plan, the length of pipes should be calculated, as well as the number of reinforcement required for connection and turns.

The installation of a heating system from polypropylene pipes is possible in two scenarios:

- The upper spill is a scheme of work based on a self-key, which arises as a result of the difference in water temperatures. The top spill can very often be found in private houses, because for his work there is no need to buy expensive pumping equipment. Everything happens in a completely natural way, and the system is reliable, durable and easy to operate.

- The lower spill is the movement of water through the operation of the pump, which is enforcing it in the heating circuit. Such an option is not suitable for multi-storey buildings (at home above two floors). In addition, together with pumping equipment, you can use pipes of a small diameter and the wiring of almost any configuration - it does not matter here.

We hope this article will help you in the work on the installation of sandwich pipes with your own hands, soldering of polypropylene pipes and the replacement of old highways. The installation itself is not so difficult, the main thing in this business is to competently select products and correctly compose the scheme of their location in space.