Quartz sand: Application and properties Building materials

Natural quartz in crushed form, quartz sand, indispensable in industry and a variety of construction spheres. It is considered one of the most pure and high-leveling varieties of molding sand. The article illuminates the characteristics of this inorganic mineral and the area in which it is in demand.

Content

Classification of quartz sand

At location

- River - the cleanest. On this quartz sand the price is higher than on all other types of material.

- Sea is his small grace of stirred with clay and aeuritic parties. It does not have such great demand as his river "fellow".

- Onsform - fractions are characterized by an acute angular shape with a rough surface. In the total mass of the material, impurities are impurities and land. Concrete and solutions of plaster produce, applying fresh sand.

- Mountain - grains have the same form as the elements of the rampant sand.

- Pogrebnaya (soil). Mineral is hidden by the ground and clay layer. These are fractions of an acute angular shape with a rough surface. Among other types of sand is the most suitable material for construction.

According to the method of mining

- Natural (retranged) sand is the result of the destruction of quartz rocks due to the immediate effects of water, wind and other natural phenomena. The returned sand is called due to the rounded and smooth form of quartz grains.

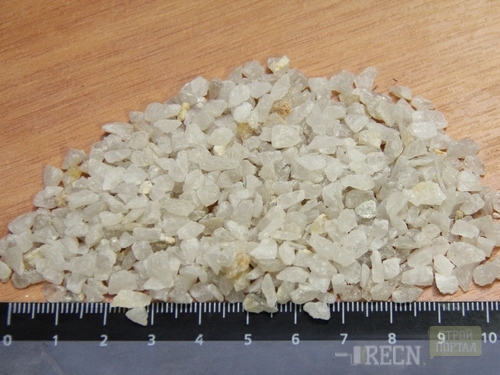

- Artificial (crushed) sand - get in the process of crushing veins from quartz. The quartz rock is exploded, thus producing different size and incorrect, more often acute-angled form, mineral elements that are divided into fractions. From natural sand, artificial is favorable with monominerality (contains about 98% silicon oxide IV), a homogeneous mass (no organic impurities), a sufficient threshold of resistance to the influence of chemical and mechanical factors.

In the form and magnitude of the grain

The magnitude of the grain:

- Small sand - grain size ranges from 0.05 mm to 0.25 mm.

- Middle sand - from 0.25 to 0.5 mm.

- Large - no less than 0.5 and no more than 3 mm.

Grain form:

- Rounded.

- Half-round.

- Acute.

Color quartz sand

Coloring mineral, processing it with a special coating using epoxy and polyurethane resin. As a result, an environmentally friendly substance with a wide range of applications is obtained.

Properties of painted quartz sand

- Adoptedly withstands chemical "attacks" - not amenable to solvents.

- Not afraid of mechanical distortion, abrasion.

- Does not fade from the action of sunlight.

Screen Sand Applications

- Used in creating injection marble stones.

- Add to polymer flooring.

- It is part of the decorative plaster.

- Present in the composition of the road flooring, which reduces gliding.

- Enabled in landscape work.

- As an adorning element, they are actively used in zoology, aquaries and gardening.

- Found an application in children's and "Handmade" creativity.

Distinctive properties and quality of quartz sand

Quartz sand - a substance, a positive feature of which are strong granules, well carrying mechanical, natural and chemical destructive impact.

Clean quartz sand consists of 99% silica. The composition of the crude material is rich in heterogeneous impurities: ferrum, manganese and potassium oxides, carbonates, field sphaw, clay, a certain number of precious metals. They paint the gravestone in yellow and reddish-brown shades. Purified quartz sand - white with milk tint material.

Among other positive properties of this substance:

- monomineral substance with homogeneous consistency;

- has a high intergranular porosity;

- it has a large dirt capacity and good sorption properties;

- the material can be painted in any shades and colors;

- chemically inert - does not react with other substances;

- it has good flowability;

- long serve - the grains are almost not subject to abrasion;

- it is used for brake structures of locomotives and railway cars;

- takes part in removing metal corrosion.

Stamps of quartz sand

Each variety of molding quartz sand is assigned marked. It is expressed by the following article: the middle sieve class of the main fraction belonging to the category. In practice, it looks like this: Mark 2K63A indicates the concentration of the grain composition of natural quartz sand class 2k, category A. All brands and designations of quality quartz sand contains GOST 2138-84.

Mining and processing of quartz sand

The bottom of the river and the flooded channels are the territory of the production of this type of sand by hydromechanical excavation. The material is also obtained in an open way in a career.

The following process is enrichment, during which the mined material is thoroughly washed and purified from various impurities. This time-consuming and cost-effective process is a prerequisite for the preparation of sand to future use in various areas of human activity.

Then the quartz sand is dried at 800 ° C and with the help of a sieve rumble on the fractions:

- sand - a mixture of grain elements measuring 0.1 - 0.4 mm;

- large sand - particle size is 0.5 - 1.0 mm;

- quartz flour - has a size less than 0.1 mm;

- quartz crumbs call grains of 1 mm size.

Quartz sand applications

The good sorption properties of this type of sand made it an indispensable material for the operation of cleansing water filters for filtration systems that purify water in the pools.

Filters are loaded preferably crushed quartz sand - it has a small bulk density and good porosity. Such indicators make it possible not only to filter a large amount of water, but also improve its quality. The retranged quartz sand is washed faster than crushed.

The stability of the material and its immunity to factors of various purposes explains the widespread use of quartz sand in the production of cement, decorative and finishing elements, asphalt; Use in plastering facades and interior, for decorative designer work. High indexes of homogeneity make it possible to add sand into the composition of dry mixtures, concrete and polymer concrete, its use in sandblasting works as a bulk substance.

In construction, all the parameters of the material are attached great importance. For example, the quartz sand density in loose form is 1500 kg / m3, but may increase to 1700 kg / m3. In a substance with such a density indicator, higher hygienic characteristics are pure dry quartz sand, which can be used in the process of repairing in the dwelling.

Quartz sand is used in the manufacture of glass, faience and porcelain, fiberglass, enamel, paintwork, in the foundry industry.

As an extinguishing element, the material is suitable in creating electric fuses. In sawing stone, in the process of grinding lenses, quartz sand found the use of abrasive sand qualities. The production of steel and refractory products is connected with sand from quartz. Another sphere where quartz sand is very popular - landscape design.

Sukhoi quartz sand in the form of a substrate found the application in creating platforms for helicopters, arrangement of stadium territories, tennis courts, football fields and treadmills.

The most original way uses quartz sand industry catering - coffee is prepared on the sand.

New comments

Add a comment

To send a comment you need authorize.

Why not wrote about sandblasting sand? Very important industry.

Sandblasting with sand, there is such, as well as soda can be used. The advantages of soda is that it is soluble. No need to remove the workplace. Although I myself did not try.