Roofing flat roof with her own hands Construction

The process of erection of a flat roof cannot be called complicated. Therefore, these work can be performed by the personnel without referring to specialized construction companies. Learn more about how the roof of a flat roof is performed - hereinafter.

Content

Basic moments

In the design of this roof, metal and wooden beams are used, due to which the load is uniformly distributed over the supporting walls of the construction. The beams are mounted and fixed primarily. Then the rest of the roof frame is already being erected. Mounting work begin with the preparation of a flat roof plan. It takes into account all the nuances and features of the future design.

The support beams should be quite reliable, because "on their shoulders" lies not only the weight of the roof itself, but also some additional loads. In particular, the addition pressure is provided by various elements of communication, which are located in the attic and roofing. Another load comes from the weight of a person who repairs or serves roof. In addition, it is impossible to forget about the snow and wind, which also create additional pressure on the frame. So, it is atmospheric precipitates for a flat roof, due to the lack of a skate, are the main load. To properly choose the dimensions of the support beams and determine the load, it will be useful to learn the technology of how neighboring houses with a flat roof are built in your area.

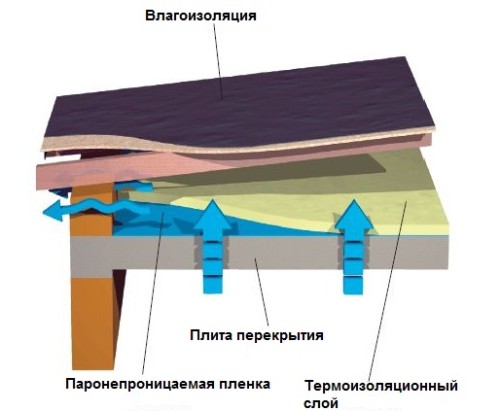

To the flat roof of a better quality, in addition to the support beams, it is necessary to choose the right coating. It must be durable and reliable. In addition, you need a high-quality roofing material that has good performance characteristics. In addition, it is important to properly perform work on hydraulic and vapor barrier. In the small-caps buildings such roofs often made of large slabs, which set a layer made of insulating materials.

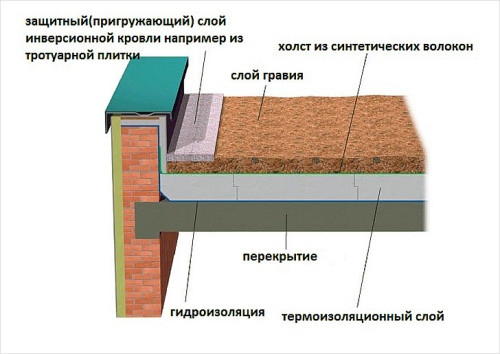

In the stacked plate, steam, which protects against ingress of moisture. As the material for this layer is frequently used polymer-bitumen film, fortified with fiberglass. Its edge plant in vertical overlap, and stitches propaivayutsya. When this is done, it is possible to lay the insulation. If the heat insulator used keramizit, you first need to be coated with a concrete screed. When using lightweight polymeric roofing insulation usually glued directly on the vapor barrier. The next layer is laid waterproofing, which is most important for the roof. This layer more often referred to simply as "pie." Usually it is made from a membrane or polymer-bitumen materials.

The cost of roof flat roof - is quite high, so it's best to perform their own, without the involvement of the specialized companies.

Variety of flat roofs

To date, there are several types of flat roofs:

- One of the most popular options is considered a soft flat roof, which is also called traditional. Its frame is load-bearing plate, on top of which is mounted paroizolyatsoinny layer and the insulator. As a material for this purpose is often used mineral wool. Used for waterproofing materials based on bitumen.

- Over time, soft flat roof design has been improved. This improved version is called - inversion flat roof.

- Operated types of flat roofs. Their base is usually made rigid enough. Such a roof can be used safely for various needs in the economy. Under the base of the roof poured concrete floor, which can provide the desired bias to drain precipitation. You can still use the decking. Warmed layer on such roofs undergoes various kinds of stress, so is used as a heater material having high compressive strength.

- Unexploited kind of flat roofs. For such roofs does not require installation, insulation and waterproofing.

Depending on the purpose of the construction, the method of arrangement of the roof is selected. The premises are heated and unheated. For each of them, different types of flat roofs are used. So, for unheated buildings, a flat roof with a small bias is suitable, which is necessary in order to remove the precipitation from the surface. In addition, it is easier to remove snow from such a roof. In some conditions, it can fall from the roof itself. The roof of this type is performed from several reference blocks, which is stacked with wooden boards. It is mounted for a waterproofing reservoir from the rubberoid. Unfortunately, such a simple design is usually short-lived, because of which it is possible to periodically repair it. When attaching a roll material, it is necessary to observe the step between the rails at 75 cm. At the same time, the planks should not interfere with the removal from the roof of moisture. In order for the precipitate without problems can be drained from the roof, its tilt must be at least 4%.

As for heated premises, the roof design is somewhat different for them. Today there are quite a lot of technologies on the construction of such roofs. If you decide to make the roof of a flat roof with your own hands, then it is best to use the easiest way. The order of installation work is as follows:

- So, as the basis, reference beams are used here, and the flooring is located on top of them. They need to be laid a waterproofing layer from the frontieroid. It is important that the rolled material is located with an overlap at 12-16 cm.

- Next over it is covered with a clay insulation, slag and other necessary material. At the same time, remember, in which direction there will be a bias to run off the roof.

- The insulation is aligned, and over it is made cement screed with a thickness of approximately 4 cm. This will avoid random damage to the roof during the harvest of precipitation from the roof.

- You need to wait until the screed is freezing, and then it must be treated with a bitumen primer. In addition, it should be done so that the precipitation and melting water do not delay on the roof. To do this, towards the edge of the roof make a small bias.

- Then you need to start gluing a roll carpet. If between the walls of the house is less than 5-7 meters, then for a support beam, you can use a simple wooden beam with a cross section of 100 by 150 mm. Alternatively, another metal beam is suitable. Then between parts of the design, the distance should be at least 1 m. These all nuances are usually reflected in the roof drawing of a flat roof.

Hearth roofing

Flat roof has a lot of advantages. And one of them is that it can be insulated both during construction and after it - during operation. Moreover, this is allowed both from the inside and outside. It is advisable first to insulate it from the outside and wait for the winter. If insulation is not enough, then you can equip an additional layering layer on the inside.

More recently, such roofs were insulated with rigid plates of thermal insulation. But this method is bad because due to it, the load on the roof is greatly increasing. Therefore, when more modern materials appeared, they began to refuse and now it is almost not used.

Today, flat roofs are increasingly insulated with basalt mineral wool. This material has a lot of advantages - he has a relatively low weight and, at the same time, it is able to provide good thermal conductivity and waterproofing. In addition, the Minvat is not subject to mechanical effects and does not burn. Thanks to these properties, it began to be used as thermal insulation material. As for internal insulation, it is easier to use refractory layers with a thickness of 5-6 cm, made of expanded polystyrene foam. Plates are mounted quite simple. To do this, wooden bars are attached to the ceiling every 45-50 cm, and the plates of polystyrene foam are installed on them. They are recorded with mastic.

Monolithic concrete roof

Metal beams are usually used as supporting elements for such roofs. At the same time, their length is selected depending on the desired width of the roof. If it does not exceed 4-5 meters, then it is enough to take the beams with a length of 160 mm. The most suitable material for the fill of the roof screed is perhaps the concrete brand 250 is considered. In order for the solution to be properly consistency, it is recommended to use a concrete mixer when it is prepared, and not mix it manually. Moreover, all components of the solution take in the right proportions. So, on 7 buckets of rubble you need 3 cement buckets, 2.5 buckets of water and 4 sand buckets. If required, the solution can be supplemented with water in more. Further on the lower beams it is necessary to fix strong bars, and the rubberoid to the surface. After that, the reinforced grid is stacked in the beam direction. So that it does not randomly slide, when pouring a screed of a bond of bonds should be fixed with something.

The grid must be fully covered with concrete solution. For this, down several parts of rubble. Due to this, it is possible to make a gap between the grid and the rukeroid between the grid and the rubberoid. The screed from the concrete should not be less than 17 cm. At the same time, keep in mind that it is impossible to pour concrete in the bands. So that the pouring turned out to be high-quality, it is best to pour the entire area of \u200b\u200bthe roof for one day.

When the fill will be completed, concrete must be tamped with a vibrator or, in extreme cases, manually. During this work, try not to break the reinforced grid and do not shift it. After that, the concrete needs to be coated with a polyethylene film. This reduces the rate of evaporation of moisture from concrete, and this will serve as a protection of the upper layer from the formation on the surface of the crack. Concrete under the film is usually left for three days so that he can grasp and dry. After drying it, the layer of insulation is poured, while observing the previously specified slope. It will only be left to make a screed and mount the rolled carpet.