Laying corrugated roof Construction

Professional flooring is one of the most demanded materials for finishing the roof. In the market, it is represented by a wide range, therefore, with the help of such a finish, both tasks are solved - technical and aesthetic. But a qualitative result can be achieved only with a competent approach and knowledge of all the features of the classification of the professional flooring, choosing it for a particular purpose, as well as the rules of installation. You will learn from this article about all the features of such a roof.

Content

- Advantages and disadvantages of professional flooring

- For whatever buildings fits professional flooring?

- How to overlap the roof of a professional flooring?

- What to take a cornet for the roof?

- Preparation of instruments and materials

- Slinge system for styling of professional flooring - technology features

- How to roof the roof of a professional flooring?

- Video

- Conclusion

Advantages and disadvantages of professional flooring

Before covering the roof of a professional flooring, any owner of a private house is asked by the question of his advantages. Knowledge of all advantages and will determine how much this roofing material is suitable for implementing the desired project.

Advantages of professional flooring is:

- Excellent strength.

- Resistance to corrosion.

- Durability and reliability - the life of at least 50 years, although manufacturers are guaranteed usually for a period of up to 20 years.

- Fire safety.

- The smoothness of the surface - eliminates the weighting of the roof in the winter period, the whole snow rolls down.

- Affordable price.

- The widest range of colors, shapes, sizes.

- A good level of sealing of roofing pie - due to the large size of the sheets.

Important! Given all these features, we can safely say that the profiled sheet is a universal, almost perfect roofing material. The only thing that somewhat reduces its attractiveness for consumers is a noise background during rain, when drops fall on the metal, as well as the risk of corrosion development, if the protective polymer layer was broken during transportation or during installation / operation.

For whatever buildings fits professional flooring?

The possibilities of this material are very broad, which is due to the variety of types of profile sheets.

With a competent approach, the roof coating from the corrugated floor can be made in private buildings and industrial buildings. Main conditions 2:

- the right choice of material brand;

- clear knowledge of installation technology.

Important! Before deciding on the material, browse the photo of the roof projects from the corrugation. Familiarize yourself with different design ideas so that the roof decorated was not only reliable and durable, but beautiful, original and harmoniously fitted with the overall stylist of the construction.

How to overlap the roof of a professional flooring?

The process of such an arrangement of the roof, as in any other case, implies several stages of work:

- Selection of material.

- Preparation of materials and tools.

- Creating a rafting system and the bottom of the roofing cake.

- Directly laying a corrugated roof.

Important! Each process will be responsible for each process, perform work, adhering to professional recommendations. In this case, you will not have difficulties, and you can properly cover the roof with your own handwritten.

What to take a cornet for the roof?

The choice of professional flooring is carried out in several criteria:

- price;

- building type;

- type of material based on the quality of the external coating;

- the angle of inclination of the roof;

- strength characteristics.

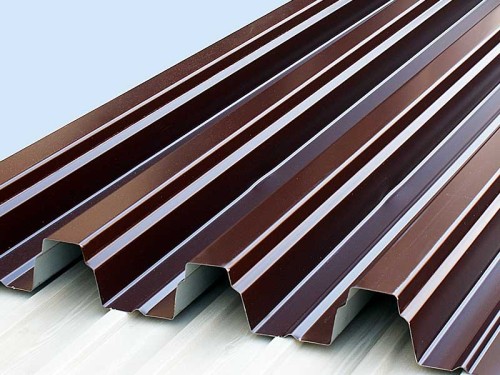

Types of materials based on the professionalist

Almost all manufacturers of professional flooring produce a wide range of products, each model range of which is characterized by production technology, in particular materials used for casting. From what exactly the profiled sheet is formed, its final cost depends.

To date, there are such varieties:

- Professional flooring from ferrous metal. This option is the cheapest. Suitable for roofing during the construction of utility buildings in the country or garage. In principle, it can also be used to finish the roof of a residential building, if it is pre-painted with your own hands.

- Professional flooring from galvanized steel. Another inexpensive version with excellent strength characteristics. The only minus of such a material is not such an attractive appearance, like more improved modern models. Nevertheless, they make such a roof and in residential individual homes, use galvanized sheets for canopies, garages, hozpostroops on the plot.

- Polymer-steel sheets. The optimal option for creating a beautiful durable roof of a private cottage. Polymeric spraying perfectly protects against any adverse effects, and also expands the possibilities of color solutions. It gives almost unlimited design capabilities. The only nuance is worth such a material for an order of magnitude more expensive than a black metal professional or galvanized steel.

- Copper and aluminum sheets of professional flooring for the roof. This is the most durable and reliable roofing materials not only in the group of profiled sheet, but also among all varieties of materials for the roof finish. In terms of its characteristics, both options satisfy all modern construction requirements regarding the technical side. In addition, for example, the copper roof looks very solid and expensive, but it is worth it is not cheap.

Important! There is another line of decorative professional flooring, which includes bent, perforated or embossed models. They do not completely cover the entire roof space, but as additional elements are used if the goal is to create the most original and beautiful design of this part of the building.

Brands and appointment of the professionalist

To the roof of the roof of the corrugated floor, be sure to pay attention to the labeling model you like. Each of the species is designed to arrange a specific type of roof.

Important! The digital value indicates the height of the wave, alphabetic - on the material and structural features.

Standard values \u200b\u200bare as follows:

- For light roof, materials with marking from C-8 to C-35 are suitable, the most popular of which are C-21, C-35.

- A more solid roof can be created from materials of type NS-35 or NS-44, which are additionally strengthened by ribs. Mandatory condition for the installation of such a roof is on the roof - the shadow step is up to 0.8 meters.

- Capital roofs and even interhesive floors can be made by chassis brands N-60, 75, 114. It is a more durable material that is also equipped with ribbies to maintain the original form.

- In order not to create additionally drains, take the RN-20 professional flooring. It not only has high strength rates, but also equipped with special water chutes.

Important! The cost of overlapping the roof of the roof is completely dependent on your design requirements and the selected material.

Tilt angle

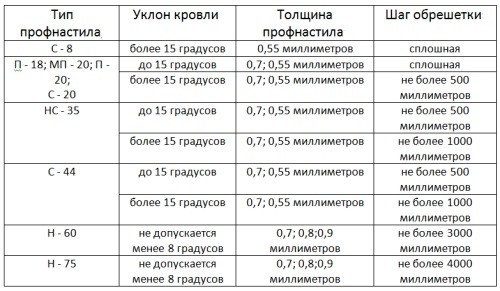

Another criterion for choosing a professional flooring is the compliance of the brand to the permissible corner of the inclination of the roof of the roof. You definitely not be mistaken if you consider the requirements given in this table:

Dimensions of the roof made

The dimensional grid of the profiled roofing sheet is wide enough. Depending on the type of design and sizes of the roof of your building, select the material in such a way as a result of obtaining a minimum amount of joints and eliminate the considerable proceedings of the professional leaf.

The dimensions of the roof of the roof are as follows:

- Width - 980-1850 mm.

- Thickness - 0.5-1 mm.

- Height - 15-130 mm.

Important! Choose the width, given that the sheets are necessarily stacked. The corrugation height of the proflist directly affects the external volume of the roof. The thickness causes the reliability and strength of the coating.

Additional materials

The roof of the roof of the corrugation will be much more convenient and easier if all additional components you choose from one series.

You will need such details:

- The skating bar, which protects the place of the inclined fracture or connecting the skate.

- Face planks, which close the ends of the skates.

- Planks for the arrangement of endanda. It is useful if there are internal junctions of the roof rods.

- Planks for registration of internal angles - to the greater the decorative load.

- Planks for closing outer angles - their main function is to prevent water from entering the joints.

Important! Not all items from this list are needed for each roof. What exactly will be useful to you, determine the design features of your roof.

Preparation of instruments and materials

This stage consists of 2 processes:

- delivery to the object of the proflist;

- preparation of all tools and consumables.

Transportation of professional flooring

Despite the fact that the professional flooring is durable material, its outer coating can be damaged, and with a small thickness of sheets, deformation or formation of dorms is possible, if not comply with certain rules in the process of transportation. They are as follows:

- To fulfill all unloading and loading works, it is desirable to have helpers manually. Their amount determine in this way - 1 person for every 2 meters of sheet length.

- Move the material from the place in place only in a vertical position, excluding large devices and shocks over the surface.

- All sheets fold only horizontally, on a solid and smooth surface, the length of which is much larger than the length of the sheets.

- In the process of transportation is not allowed speed of movement more than 80 km / h, sharp braking.

Important! By choosing a suitable model of professional flooring, be sure to check the absence of any defects - scratches, chipping, irregularities of the coating. If it did not work out to buy the entire volume of material from one series, check out the compliance of the shade on all products.

Tools and consumables

In order to arrange a rafter system and high-quality fixtures, prepare all the tools and materials necessary for work, adhering to this list:

- Wooden boards with dimensions 30 * 100 mm.

- Wooden bars with parameters 50 * 50 mm.

- Little bars - cross section of 60-70 mm.

- Wood protective solution.

- Hydro and vapor insulation materials.

- Mounting sealant with water-repellent properties.

- Galvanized roofing screws with a cross section of 4.8 mm with a length of 28-40 mm with a set of sealing neoprene gaskets.

- Roofing nails.

- Drill.

- Building level.

- Circular Saw.

- Screwdriver.

- Hammer.

- Brush with mild pile.

- Screwdrivers.

- Black-grained hacksaw - for cutting metal.

- Construction stapler and several packs of brackets to it.

- Roulette.

Slinge system for styling of professional flooring - technology features

The competent organization of the rafter system directly affects the strength and reliability of the entire roof. Therefore, at this stage, comply such rules:

- Pre-process all wood materials with a protective solution. At the same time, take into account the sequence and time of the impregnation, designated in the instructions from the manufacturer of the drug.

- Place the waterproofing film by bands in a horizontal position, without much tension or sagging. For fixing, use building brakes or assembly tape, but be sure to make a gap of the film of one row to another at 15 cm.

- For the first layer of the crate, use wooden boards with a cross section of 50 * 50 mm. Boards Stay from the cornice line vertically, withsting a step of 60-80 cm.

- For the second - wooden bars 30 * 100 mm. Place them in a perpendicular direction. Step Select the one that matches the type of your professional flooring according to the table shown above. The accuracy of the location is determined by level.

- All items fix with roofing self-drawing and nails.

- The space of funds, chimney, the skate, fire and ventilation holes, sort out a solid crate, tightly sewed the boards to each other.

- On top to put a diffusion membrane film by fixing it with nails with wide hats.

How to roof the roof of a professional flooring?

To correctly cope with the task, how to fix the roof corrugated floor, follow the following instructions:

- Set the lags by which it will be convenient to raise sheets to the height or take a sliding staircase for this purpose.

- Put protective clothing, soft shoes and be sure to gloves.

- Consistently lift 1 sheet.

- Only on the roof remove the protective film from the leaf.

- Start the installation of sheets from one of the ends.

- Attach the first sheet so that it goes beyond the cornice line by 3-4 cm and spoke a little behind the end line.

- Temporarily secure 2 screws - the skate and sweep.

- Remove the metal dust from the surface of the brush.

- Check out the level of horizontal.

- Lay the following sheet by taking out 1-2 waves or stick to these rules:

- an angle of inclination up to 15 degrees - Taste is 200 mm;

- the angle of inclination from 15 to 30 degrees - the backstage is kept in 170 mm.

- Align both elements horizontally and relative to the end, fasten with screws in 40-50 cm increments.

- Lay on 2 sheets.

- Align the entire design of 4 elements and securely secure self-pressing in each 2-3 wave. The fastening itself should not be too tight or breaking.

- Fill in all the joints and gaps, including the holes near the fasteners, water-repellent sealant.

Important! After laying a professional flooring, step on the roof only in the breaks of the waves.

Installation of complex seats

Sequentially settle all complex places according to such a scheme:

- Hearing windows:

- remove sheets of 2 parts;

- lay them, distinguishing the bottom plank.

- End:

- for the ends, take the bar, the length of which is 2 meters;

- mount them in the direction of the Svet-Konk with the allen up to 100 mm one on one and 1 wave on the main coating;

- fastening Perform a step in 1 meter.

- Konk:

- the skaters are attached to the allen up to 150 mm with the direction of laying to the side, where the wind is less likely to blow;

- the step of fixing parts is 200-300 mm.

- Install snowstanders to provide the desired security level.

Video

Conclusion

Professional flooring is practical, comfortable, beautiful and inexpensive roofing material. Perform its laying right - and you are unlikely to regret your decision.