Monolithic overlapping with their own hands Construction

In the event that the device of inter-storey overlap is impossible with the help of concrete slabs of factory production, create a monolithic overlap directly at the construction site. The size of the slab depend on the building structure, which is displayed in the project. To determine them, calculate the monolithic overlap in accordance with the requirements of SNiP 52-01-2003 and SP 52-1001-2003.

Content

Some rules for calculating the monolithic plate

- To determine the span of the reinforced concrete plate, it is necessary to measure the width and the length of the room (the distance between the opposite walls). The size of the slab itself will exceed measured values \u200b\u200bto part of the thickness (at least 100 mm) of bearing walls.

- When determining the geometric parameters of the slab to simplify calculations, it is considered as beam. All calculations are produced for one meter beam, and then apply the results of calculations for all overlap.

- The calculations take into account the static loads of the slab during operation (placed furniture and other interior items) and dynamic. Distinguish concentrated, uniform and uneven loads.

- The monolithic overlap in the cottage type house is customary to calculate the load Q1 \u003d 400 kg / 1 m². If the thickness of the monolithic overlap is 100 mm, the total weight of the design should add 250 kg / m² plus another 100 kg / m² (weight of screed and finishing materials). A reliability coefficient is also used equal to 1.2. Thus, the total load will be q \u003d 900 kg / m².

- The thickness of the monolithic overlap is proportional to the magnitude of the span, which is expressed as 1:30 (there should be no less than 150 mm).

- The number of reinforcement rods used can be different. For example, for reinforcement of 1 rod rod meter with a pitch of 0.2 m rods - 5 pcs with a diameter of 14 mm. The same area of \u200b\u200bthe reinforcement cross sections can be obtained by applying rods in the amount of 7 pcs with a diameter of 12 mm, laying them in increments of 0.14 m or 10 rods (10 mm) in increments of 0.1 m.

Main stages of mounting formwork for monolithic overlap

The monolithic slab overlap is mounted after the construction of the bearing walls to the current level. The formwork is a construction collected from the sheets of moisture-resistant plywood and vertical supports. The humidity of plywood sheets should not exceed 25%. Supports can serve as telescopic racks made of metal pipes or wooden bars.

So that the formwork had the necessary margin of strength (for plates a thickness of no more than 300 mm), its installation is performed in the following order.

- Recovering 200-250 mm walls set supports under the entire area of \u200b\u200bfuture overlap. Distance between supports - 1 m.

- On top of the supports lay a timing with a cross section of 50 × 150 mm, orienting it along the long side of the formwork. The distance between the bars is 2 m. The edges of the BRUSEV must be attached to the wall.

- Across Bruusyev stacked with a step of 500 mm another row of Bruusyev. In places of intersection, the elements are firmly connected by nails.

- A verification of the vertical position of the supports and the horizontal structure collected from the BRUSEV is performed. When detecting deviations under the support put pieces of plywood for alignment.

- When using wooden supports (for this, a timing is suitable with a cross section of 150 × 150 mm), the disclosures of 30 mm thick boards for additional strengthening of the structure are set.

- On the surface of the bearing walls and partitions, vertical side parts of the formwork framework are collected, over the horizontal crate of the bars, plywood sheets are laid.

Note: Instead of moisture-resistant plywood for mounting the bottomworks, you can use special ribbed metal floors.

Reinforcement of monolithic overlap

The assembly frame of the monolithic overlap consists of two parts. The first, located in the lower tier, works on a stretching, and the second, mounted in the upper tier - on compression. For reinforcement, the bars with a diameter of 10 and 8 mm are most often used, the nipping of the reinforcement in the places of its intersection is performed with a wire of 1.2-1.5 mm.

Basic rules for assembling reinforcement frame

In reinforcement, the following rules must be followed:

- between the side details of the formwork and reinforcement frameworks should be a gap at least 20 mm;

- the monolithic overlap device should be so that the reinforcement closes the concrete with a thickness of about 25 mm from above and below;

- between the upper and lower reinforcement tiers, the distance should be within 90-100 mm;

- for the device, the interval between the tiers of the valves, remote locks with support legs are installed;

- in the case when the length of the rod with a diameter of 10 mm is insufficient for the reinforcement of the overlap, it is possible to build up with a minimum ink and 480 mm;

- prunev connections in reinforcement tiers are located in a checker.

Monolithic overlaps: reinforcement technology

Sequence of actions when assembling a metal frame (phased instruction).

- In order for the reinforcement of the lower tier to be closed with a layer of concrete, plastic locks are installed on the sheets of plywood with a step of 1.0-1.2 m.

- In a step of 200 mm, reinforcement rods are stacked in the longitudinal direction. Between the supporting supports, in the middle of the design, there must be additional bars.

- In the perpendicular direction relative to the first row of rods, the second row is stacked. Stacking step is observed as the same as for the first row.

- Wire made of soft metal, with the help of a special hook, the rod of rebounds of reinforcement in the places of their intersection are performed.

- In a checker manner, plastic clamps are installed on the bars of the lower tier at an angle. The distance between them should be equal to 1 m.

- The upper frame is mounted in the same order as the bottom.

- At both edges with a step of 400 mm, P-shaped connections are attached to rods.

Pouring concrete

Monolithic reinforced concrete floors are created using M200 brand and higher concrete. The components of the solution are water, crushed stone fraction 5-20 mm and pure, sacred sand. Fill rules are as follows.

- The monolithic overlap is poured in one hand: otherwise the strength of the structure will not be provided.

- The solution is evenly applied on the bottom of the formwork. The thickness of the solution layer is limited using lighthouses.

- The air from the concrete mass is removed using a deep vibrator. With its absence, a metal rod, which is often singered with a solution throughout the fill area.

- The laid concrete should be covered with a plastic film for several days: it will ensure uniform frozen and prevent cracking.

- After 28 days, formwork dismantle, it is possible to continue construction. If it is necessary to build the walls of the next tiers before, work is performed, without disassembled formwork.

How to create team-monolithic overlaps

In the event that the parameters of the structure allow you to apply standard stoves for the device of inter-storey overlap, you should take care of the presence of lifting equipment. The standard plate does not exceed 9 m. With a greater length of the span, additional supports or bearing walls are erected.

Features of the installation of collected monolithic inter-storey structures.

- Before laying the plate, the levels of bearing walls are checked: the drop must not exceed 10 mm.

- In the place of laying the plate, the substrate from the cement-sandy solution is laid, which will ensure a more dense fit to the wall.

- Plates are fed to the placement location using the Sling system.

- If there is a mortgage fittings welded.

- Gaps between adjacent plates are filled with solution.

- The holes of the hollow plates on the side of the outer walls are partially filled with a solution to prevent the formation of "cold bridges".

- On top of the collection-monolithic overlap, an aligning screed is performed.

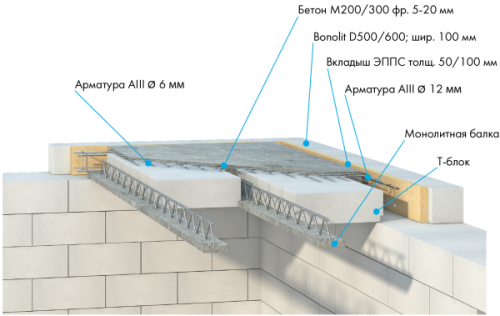

Aerated concrete: Monolithic overlap according to modern technologies

Aerated concrete is used not only for the construction of walls, but also to create overlaps. Such designs are different:

- high strength (able to withstand the load up to 600 kg / m²);

- low specific weight;

- ease of installation;

- long service life;

- environmental safety.

Separate elements included in the composition of the collection-monolithic design are manufactured on specialized enterprises and set them such dimensions: length - up to 6 m, width - up to 1.8 m, thickness - 0.3 m.

The installation of overlaps from aerated concrete blocks provides for the installation of reinforced concrete beams. Such a reinforcing design is called Trigon. Some features of mounting monolithic overlap are as follows:

- Interior partitions are up to 10 mm below the overlap. This will reduce the load on the ceiling plates, will prevent their destruction.

- Flooring blocks are placed in place of lifting equipment using soft sling.

- Plates should be based on the carrier parts of the overlap to a depth of at least 1.25 mm.

- Before laying plates on the bearing walls impose a fastening solution.

- On the perimeter of the bearing walls, two levels of the reinforcement framework are laid.

Compliance with slab laying technologies contributes to the creation of a perfectly smooth surface of the ceilings. In the conclusion of an article on how monolithic overlaps are created - a video visual demonstrating process.