Drill and perforator - what to choose Instruments

Today in construction stores you can find many different tools, so it is very difficult to choose the right one for one or another task. Most often, the masters are wondering what is better drill or perforator? Therefore, in this article we will try to figure out all the nuances and answer it. Let's start with the main differences in the perforator from the shock drill.

Content

What differs drill from the perforator

The drill of the shock action is perfect for the next type of work:

- Drill holes in different materials (including wood and plastics). It is possible to disable the shock function if necessary.

- Do (break) holes in some solid materials. Using the shock function, you can make a quickly quick hole even in brickwork.

- Watch and turn off the screws, screws and screws. Only this should be done with a shock function disconnected.

With the help of the perforator, in addition to the above, you can:

- Punch holes in very solid materials (for example, in reinforced concrete).

- Use various types of chisel for loaves. This feature is allowed to apply if you need to make a small break or a chute in a concrete or stone wall.

Between these tools (shock drill and perforator) quite a lot in common, but there are still some differences. In order to understand them better, you should first figure out the principle of operation of the drill of the shock action. It is as follows: there are a pair of gear ratchets that interact with each other. In the impact mode, their impact on the material. This principle has the following flaws:

- The harder material, the more you have to apply effort.

- Small amplitude with a high degree of return.

- Fast wear teeth of ratchet.

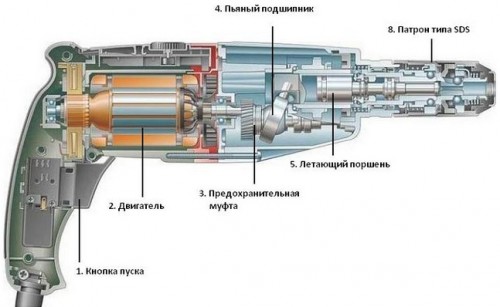

The perforator has no such drawbacks. Basically because its device is very different from the drill. In some details, its mechanism is very similar to the automatic weapon. It is especially different when working on solid materials. He has less returns and above the speed of passage. However, consumables for this tool are more expensive than for a drill.

But it does not make a reason to completely abandon the drill of the shock action. If there is no need to make holes in very solid materials, then it will be more appropriate to use it. In addition, it will cost cheaper than the perforator of the same level.

What else differs the shock drill and perforator? The difference is that the drill allows us to use conventional drills without unnecessary devices, and for this purpose, additional adapters are needed with a perforator. They make the instrument uncomfortable in work, i.e. Increase its length.

Therefore, before you buy yourself a drill perfractor, you need to know exactly the type of work that you have to do, and with what material you will work. Thus, for wood and metal, the brick walls are best to get a drill of a shock action, and a perforator will be required to work with concrete walls.

Main characteristics of tools

- Rated power. Shows how easy it is easy and fast tool can cope with the task. However, the stronger power, the greater the load on the electricity. Consequently, above the probability of departure of traffic jams.

- The number of revolutions. Determines the degree of freedom when working with a variety of materials and the necessary devices.

- Maximum drilling diameter in some materials (for example, steel, concrete and wood). This is a very important characteristic, the observance of which will help save the tool much longer.

- Adjusting the speed of rotation. Today there is a majority of new models of perforators and drills of shock action. This characteristic depends on the strength of the start button. Some devices are equipped with special disc regulators that help set the maximum number of revolutions, i.e. Even if you press the start button until you stop, the speed of rotation will not be higher than the specified one. In addition, today there are models of tools equipped with special processors that help choose the appropriate rotation speed depending on the diameter of the drill and the displayed material. There are two-speed drills in which the mechanism is used, a little resembling on the principle of operation a car transmission. It allows you to more rationally use the power tool.

- Reverse or ability to rotate the drill in the opposite direction. This feature is convenient enough to turn out the self-sufficiency or screw. Sometimes it fails to manually unscrew.

- Switch lock button. If there is a long-time job tool, using this function, it will not be necessary to constantly press the start button.

Shock drills are usually equipped with the following types of cartridges:

- Toothed (otherwise the cartridge with the key). In it, the drill is fixed with a special key included with the drill.

- Quickness. Allows you to secure drills without much effort. They hold firmly in this cartridge. The key does not apply. In perforators, the SDS-Plus fastening is usually used, allowing only special types of drills. There are also tools with ordinary patron.

There are electric drills that, when spinning screws, the optimal rotational moment is determined. To do this, specify the type of material and the desired type of work. The rest will make the tool itself.

What can I choose: shock drill or perforator?

- Tools allow punching holes in different materials, including wood, metal, brickwork. To drill concrete, you need the most powerful, that is, the perforator.

- Using special nozzles on small turnover of the tool, you can wrap screws, screws and screws.

- The more power drill, the easier it is to make a hole. But usually with increasing power, the tool becomes harder.

- Applying additional devices, you can use the electric drill as a grinding machine or a grinder.

- If you carefully exploit the tool, it will last long enough. Proper use implies, for example:

- short-term operation of the device up to 35-40 seconds;

- the use of high-quality acute drills;

- accounting for the conditions in which you have to work.

Perforators with a capacity of 800 to 1500 kilowatt and weighing from 2 to 11 kilograms are usually several large dimensions than shock drills. In such devices, the engine can be located both horizontally and vertically. In addition, many are equipped with SDS cartridges. In the technical characteristics of the tools, the frequency of strikes is usually indicated per minute and their strength. In low power devices, it is usually possible to adjust the revolutions, which allows them to be used as a screwdriver.

How to use the perforator

- Before you start, you need to make sure that there are no electrical wiring or water supply systems.

- The axis during drilling should rotate clockwise. Otherwise, the tool may fail.

- When using an additional handle, you need to make sure that it does not hang.

- Before work, it is recommended to include a tool for a couple of minutes at idle and listen to the main elements. When breaking one of them, extraneous noise will be heard.

- You need to drill with a small speed. As for the effort, it is enough for any material - from 3 to 5 kilograms.

- When drilling it is recommended to periodically remove the drill to remove accumulated dust.

- Drill metal, wood and plastic follows without the enabled of the beyon mode. For other materials, you can use impact and drilling modes.

- Before starting work, you need to check the service of the tool and to look pretty the surface with which you have to work. Be sure to read the instruction that is applied to the tool itself.

- When the works are completed, then it is necessary to clean the components of the tool and free from the particles of dirt, dust and garbage ventilation holes.

- When working with a perforator, you should wear safety glasses and mittens.

How to use the drill

Before starting work, the driver's drill is required to check:

- Tool package.

- There is a special key for the clip of the drill (if such is provided).

- Details of the drill are securely attached.

- Whether the electrocabolic and forks are working.

- Is there any damage on the handle and the case.

- How proper and clearly turns on the tool.

- Is the device at idle running normally.

- Whether there are no strong spurs in the brush collector department.

When working, the drill is prohibited:

- Work with wet structures.

- Remove sawdust and chips while working with hands. This can only be done after a complete stop of the device.

- Working on the street during snow either rain.

- Clamp and squeeze the cartridge by the passage and the configuration key in order to install a new drill.

- Work a drill with an appropriate staircase.

- Leave a drill connected to the network unattended.

Do not work drill if:

- There are damage to the cable and plug.

- There is a strong sparking of brushes.

- There are damage to the lid of the brush holder.

- Working parts of the tool are damaged.

- There is a bad switch of the switch.

- There is an extra noise and a knock when working.

- There is an emergence of smoke and smell.

- Cracks on the handle and the case appeared.