Instructions for the operation of centrifugal pumps Plumbing

Most country houses do not have a centralized water supply system. The best solution to ensure the need for water for drinking and domestic needs is the creation of wells. Effective water fence is carried out by using pumping equipment. In our article we will tell about the basic rules of operation of centrifugal pumps.

Content

Features of equipment

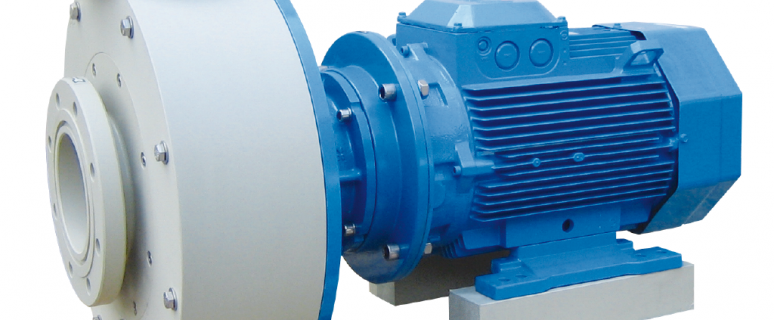

The purpose of centrifugal pumps is water intake from sandy and artesian wells. Equipment is made of stainless steel and is characterized by excellent working pressure and a small size. Some models of centrifugal pumps have a cylindrical shape. Thanks to this, they can be placed in the narrow borehole pipe.

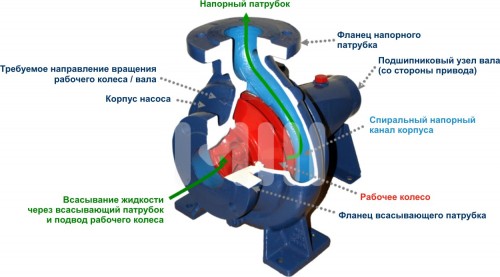

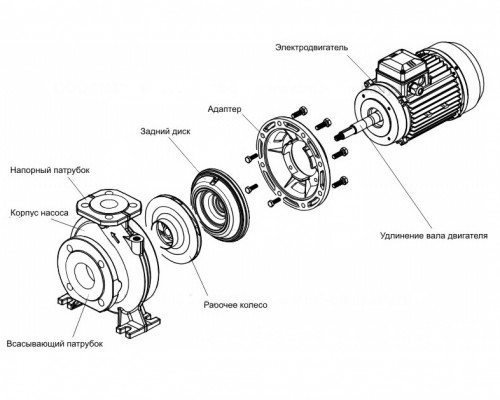

The scheme of operation of centrifugal pumps is based on the principle of radial direction of water flow. The easiest unit is a housing and a rotating impeller. When the wheel is rotated, the water is discarded from the center to the extreme part and enters the housing removal. At the same time, water gets into the central part of the wheel from the suction pipe.

There are several classifications of centrifugal pumps. Main criteria:

- number of working wheels;

- power pressure;

- the location of the shaft.

On the first sign, the equipment happens:

- single-stage;

- multistage.

Depending on the pressure created, there are such centrifugal pumps:

- with low pressure (up to 20 m);

- with middle pressure (20-60 m);

- with high pressure (over 60 m).

Depending on the location of the shaft, the aggregates are:

- with a vertical shaft;

- with horizontal shaft.

The main characteristics of the equipment are:

- compactness;

- minimum weight;

- excellent performance;

- simplicity of assembly and dismantling work;

- the possibility of smooth control of the pump operation;

- uniformity and uninterrupted water supply;

- reliable work for a long time;

- pumping of various liquids.

The operation of centrifugal pumps depends on the method of their location. Some models can work in water. Others function only above its surface.

Using ground aggregate

Installation of this type of centrifugal pumps is carried out on a pre-prepared foundation. At the same time, it is impossible to deal with the correction of the skew by placing the gaskets or tightening the bolts.

Before running the centrifugal pump to work, the following operations should be carried out:

- add lubricant to bearings;

- if necessary, tighten the glands;

- the shaft during rotation should not be encountered;

- check the gap between the gland and the unit housing (it must be within 8-10 mm);

- pour water into the pump housing;

- to check the direction of rotation of the shaft, make a trial start of the engine.

In the process of functioning of centrifugal pumps, the tightness of all connections is periodically carried out.

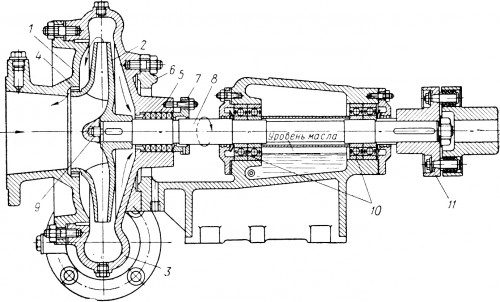

The main elements of centrifugal pumps that affect the period of their uninterrupted functioning are bearings and seals. For this reason, during the device and operation of centrifugal pumps, these nodes require the highest quality installation and care.

If the pumps have sensors to measure water and temperature pressure, then the degree of heating of bearings is required. They should not overheat. The maximum heating temperature of the bearing should be within 70ºС.

As for the replacement of oil, this procedure is carried out by 0.8-1 thousand hours of engine operation. If the bearings are subjected to ring lubricant, the ring is checked. It should rotate without any problems simultaneously with the shaft.

Checked the correct job of the glands. They should be cold. It is also necessary to monitor the preposition of leakage through the gland seal. If the water begins to leak through it, the gland must be tightened.

If the gland is heated greatly, the equipment turns on and off several times. Oil should be leaked through the seal. If this did not happen, you will have to easily be reducing the gland.

If the centrifugal pump is not operated for a long period of time, it is necessary:

- free it from water;

- remove the gland;

- lubricate all items: sleeves, rings, shaft sleeves, working wheels.

Disassembling equipment involves taking measures to prevent its accidental inclusion. During the implementation of dismantling work, the location of all nodes is noted. It is forbidden to change some parts of the aggregate.

Sealing and planting surfaces are protected from scratches, recesses and other damage. It is not recommended to re-use sealing gaskets and rings made of rubber. Especially when these sealing products lost the form or cuts appeared on them. Equipment assembly is made in accordance with the instructions for the operation of centrifugal pumps.

Submersible junction nuances

Proper operation of wells by centrifugal immersion pumps implies the implementation of high-quality installation of equipment. The installation site should be selected in such a way as:

- there was a normal access to the pump;

- there was an opportunity without problems to disassemble and collect.

The installation of the centrifugal pump is carried out below the dynamic level of water in the well to 8-10 m. If the equipment is lowered to a depth of more than 80 m, then it is necessary to purchase a pipe with a pressure of 16 atm. If the depth of the pump is not exceeded 80 m, a sufficient tube withstanding a pressure of 12.5 atm.

The pump connection with the pipe is carried out using a fitting made from brass. The adapter must be equipped with a sleeve, thanks to which the pipe diameter will not change as a result of the fitting load.

Brass fitting is used and when fixing the second end of the pipe to the ledge. The cable clutch is used to connect electrical wires of the pump and the power supply circuit. The cable mounting to the pipe is made every 2-2.5 m with plastic clamps.

The pump and the headband are connected by the safety cable made of stainless steel. Its thickness must exceed 5 mm. The cable with the pump is lowered into the well and connects to the source of electricity.

Possible malfunctions of centrifugal pumps and elimination methods

During the operation of the unit, in some cases the need arises in its stop. About possible malfunctions may indicate:

- excessive heating of bearings;

- the presence of harsh fluctuations in sensor readings;

- strong vibration and increased noise;

- termination of lubricant receipt.

Conditionally all faults can be divided into 5 categories:

- failure of the pump engine after starting;

- reducing the productivity of the unit;

- reduction of equipment pressure;

- engine overload;

- strong noise and vibration.

Engine failure

The reasons for the engine failure immediately after starting can be:

- the presence of air in the pump housing;

- loss of the density of the suction pipe;

- slip pipe blockage.

Solving troubleshooting assumes respectively:

- repetition of water fill;

- creation of a compacted suction line;

- clean the tubes.

Reducing productivity

This equipment malfunction can be called:

- air penetration through the gland in the unit of the unit or the suction pipe;

- the increase in resistance in the pressure pipe;

- increasing suction height;

- wear of sealing rings;

- clogging or damage to the working wheels.

These problems are solved by:

- tightening or replacing the gland;

- pipe checks for clogging;

- cleaning clogged nodes;

- replace damaged parts.

Reducing theft and engine overload

Reducing theft of the unit indicates:

- availability in water air;

- damage to the water pipe;

- existing mechanical defects.

A suction tube is checked for eliminating these faults, the gland is tightened and damaged items are changed.

The engine overload of the unit is associated with:

- mechanical damage to the pump or engine;

- excess of the actual number of revolutions above the calculated value;

- invalid productivity of the unit.

Disadvantages are eliminated by checking and regulating equipment, as well as replacing damaged nodes.

Noise and vibration

The main causes of high vibration and noise are:

- poor-quality equipment installation;

- minor clogging of working wheels;

- mechanical damage (bearing wear, jamming rotating parts, shaft deflection);

- weakening fasteners on pipes;

- cavitation.

To eliminate these problems it follows:

- fix reliably pump;

- clear the clogged wheel;

- replace damaged nodes;

- pull the fastening elements;

- reduce the height of suction.

Video about the features of the centrifugal pump: