How to make wax for wooden doors do it yourself Doors

Wooden products for a long time will save aesthetic attractiveness, if used for surface treatment with special wax for wood. The protected wood is not scary moisture, the mold will also not cover its surface. Oil wax for wood does not have to search in construction stores, it can be made with your own hands. About how to make it in practice and will be discussed in this article.

Content

Wax properties for wood processing of wood

Natural wax for wood has the following beneficial properties:

- ease of applying on a tree;

- harmlessness for human health;

- the ability to restore the aesthetic attractiveness of the product after replacing the damaged fragment;

- wooden surfaces covered with wax, easy to put in order: after wiping using detergent, you can apply another layer of wax;

- with the help of pigments, you can give the remedy necessary shade: Wax paints for wood can be used for decorators;

- wax protects wood from mechanical damage, makes small scratches with almost imperceptible;

- the surface of the wood is reliably protected from moisture impact: wax has water-repellent properties;

- the wax is distinguished by antibacterial qualities, it protects products from mold and rotting, and also prevents insect damage.

Tip: Given the vectors, it can be used to protect furniture, wooden floors, walls, dishes and other things.

Wax for wood with your own hands

The basis for the preparation of the wax required to protect wood can serve as various natural oils.

We use olive oil

The recipe for cooking wax is such.

- We prepare bee wax (two spoons) and olive oil (seven spoons).

- Bee wax should be reckoned and spread with a spoon.

- We add oil into wax and mix thoroughly, warming on a water bath. Mix the liquid wax for wood with your own hands until it is completely cool.

- For storage, we place wax in the glass container and close tightly with a plastic lid.

Important: Use the resulting wax for processing wooden products in this way can be used for a year. After this period, the tool loses its properties.

Jojoba oil wax

Jojoba oil-based wax is safe for humans, which allows you to handle furniture and children's toys to process. To prepare the wax, you need to do the following.

- The bee wax in the amount of 50 mg is mixed with 150 mg of jojobic oil pressed oil. With increasing the number of necessary funds, the proportion of 1: 3 of the main ingredients is preserved.

- Grinding wax melts in the dishes in a water bath, after which the oil is mixed.

- Liquid wax for wood is stirred until complete cooling.

- The resulting means is stored in a glass jar for no more than two years.

Linen Wood Wax

The process of preparation of wood processing based on flaxseed oil is largely similar to the technology described above. At the same time, some nuances should be taken into account.

- The proportion of mixing the main components: two spoons of beeswax 6-8 spoons of flax oil. The thickness can be changed by reducing or increasing the share of wax.

- Colored wax for wood can be obtained using appropriate additives.

- To accelerate the process of flossing the wax after it is applied to the wooden surface, the sequivat is mixed during the preparation.

- Store wax away from direct sunlight in a glass container. Shelf life - 12 months.

Carnauba wax

Carnube wax-based wood treatment agent is obtained from palm leaves Copernicia Cerifera (Motherland - South America). The usual beeswax for wood, unlike Karnubsky, melts already at +35 ° C. The latter is much more refined and is flakes.

In order for such wax to be used to apply on the wood, it should be prepared from it. Various additives change the density of the substance, make it plastic.

The mastic cooking technology is as follows.

- Wax flakes are placed in a metal container with a dense lid and heated on slow heat.

- Add hemp or linseed oil (any, except vegetable) approximately two times the volume of wax and heated until the wax starts to melt.

- We stir the mixture and after incomplete cooling, overflow into a glass jar with a lid (for storage).

IMPORTANT: If the mastic turned out too thick, it must be melted again and add some amount of oil. During the storage process on the surface, the film is formed, which must be removed when using the means.

Wax for furniture

For processing furniture (for example, the door of the cabinet) to the wax prepared from natural ingredients, the fourth part of the integral rosin is added. In order for the tool to acquire the necessary consistency, about 50 g of turpentine is added. Rub the wax wool cloth.

Wood applying on a wooden surface

To work, you need to have at your disposal the following:

- bee wax;

- linen or cannon oil;

- pigment additives;

- metal dishes in which you can melt the means;

- brush with a soft pile;

- wall for cleaning the brush.

Sequence of action when processing wood wax.

- The surface of the wood product should be cleaned, remove fat spots with solvent or grinding.

- Prepare wax one of the above recipes.

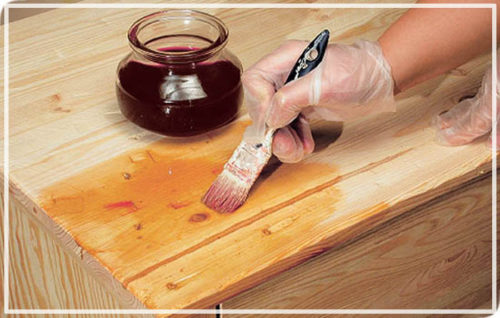

- Brush wax is applied with a thin layer, carefully distributing it throughout the surface being treated. The operation is performed in one reception, and in a short time, so as not to form influx and seams. Periodically wipe the brush to remove bunches.

- We leave the product for a while dry.

- We carry out the surface grinding cotton cloth or using a special grinding machine.

Some features of applying waxes on the surface of the doors

Before applying the wax to the door cloth, you need to perform preparatory work. All wood processing process: phased description.

- Glass removed, door handles are removed.

- The surface of the door leaf is polished by sandpaper with grainy 20 in the first stage and 90-150 on the second.

- Squares and cracks are rubbed by a putty, selected in the tone of the wood.

- The doors are cleaned of garbage and dust with a wet rag.

- On a clean and dry surface, the wax is applied with a soft brush. Excess means are removed by dry rag.

- After the wax is absorbed into the wood, the doors are grinding mechanically.

Important: the initial coating is removed before processing the old doors. All caps of nails and self-tapping screws should be recessed and disguised as putty.

After waxing, wooden doors will restore aesthetic appeal, their surface will become more resistant to mechanical damage. Wood qualities will save for several years, after which the procedure is recommended to repeat.

In conclusion - wax cooking video tutorials with expert explanations.