Brick smokehouse with your own hands Useful advice

Smokehouse in the country or in a private house is a great opportunity to diversify the diet, please yourself and your seven quality food and delicious products with a smoke. Compact portable smoke can be purchased in any specialized store, but the stationary brick installation is easy to make it yourself.

Content

Choosing smokels

Smoking technology can be briefly described as the processing and impregnation process with smoke, emanating from wood. Without a special smokehouse, such a technology for cooking is almost impossible.

The smokehouse is a fairly simple design - metal tank with grille for lays out products and removable lid. Having a desire, a mixture and minimal skills can be made high-quality smoking on their own. Moreover, both for cold and hot smoking.

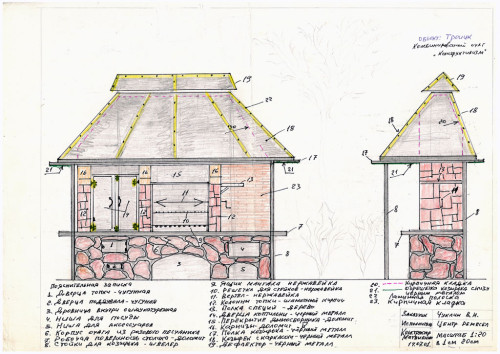

A brick smokehouse is based on a metal frame, which is placed brick. Sometimes you can not make a frame, but to start the construction process on a concrete foundation. In its device, the chimney, brazier, metal grids for the preparation of products, the smoke chamber has been preparing. From which it consists of and how the standard design is designed, you can see on the drawing of the cryptonium from the brick.

Modern technologies in the production of smoking instruments stepped forward, the problems of the deficit of such equipment today simply do not.

Speeds:

- coal grill-smokehouse;

- portable smokehouse;

- electric grill cryptile;

- gas grill-smoking;

- disposable smoking package.

For the preparation of fish before purchasing the smoke, you need to clarify how many fish you plan to prepare and under what conditions. For example, for a large company, smokehouse 60x30x30 cm. Such a smoke will allow you to prepare up to 4 kg of fish at a time.

There are also smaller options in which you can accommodate up to 1 kg of fish, while such smokers are easily moved by low weight - 7 kg. Smoking smaller dimensions are 40x31x31 cm.

No opportunity to buy a shop smoking? Take advantage of undergraduate tools and make a smoking on your own. Here are some wonderful options:

- Homework is easy to make a brick or made of metal sheets cooked with each other. Brickwork in this embodiment must be cooled with a clay solution for tightness. Wood or chips are placed in a special chamber, smoldering in the smoke-forming chamber. Smoking products resulting in thick and caustic smoke.

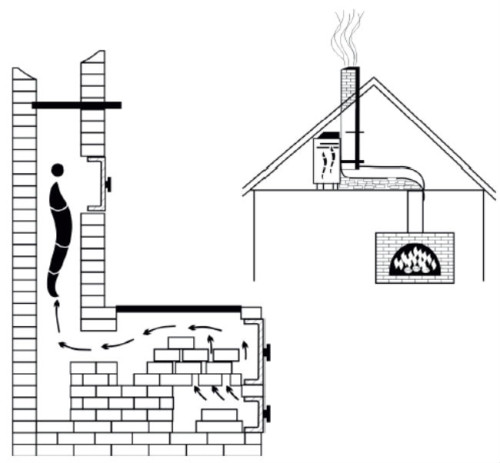

- Smoking in the chimney pipe. This is the most fiscal option, as the direct treatment of smoke products is carried out in the attic. In the chimney pipe, it is necessary to install dampers to adjust the flow of smoke, and attach hooks for chicken chickens, sausages and other things. A faint fire must be maintained in the furnace, which is divorced based on hardwood wood.

- Smokilnia can also independently be built from an ordinary barrel. To do this, in the barrel you need to remove the bottom and install it on bricks in such a way that the smoldering tree can be located between the bricks. Inside the barrels, hooks for products are driven, and the construction should be covered with a wet rogene. You can also use the grille as a barbecue. If you have a metal barrel - then the lattice will be by the way. Such a barrel is necessary to cover with a metal or wood lid.

- Brick smokehouse. Of course, you can use short-lived wooden or metal adaptations of our own manufacturers for smoking products, but if you need a reliable and durable design - then you should make a smoking brick from the brick. This is not only the most practical option, but also a stylish decoration of any plot. What a traditional smokehouse of bricks look like, you can see in the photo.

The construction technology of the right smoke brick is depicted in detail on the video.

Skolna-barbecue from brick with your own hands

To build a barbecue-smoking of a brick with your own hands, you need to be set as a set of necessary tools and materials. For masonry need refractory brick. The technology of manufacturing smokehouse consists of their following steps:

- Prepare a cement solution that should not be too liquid or thick.

- At the site of the future design prepare the pad. To do this, clean it from garbage and secure wooden sides in the ground. This is necessary to create a cement foundation.

- Cement mortar Fill to the prepared place and leave it until complete drying.

- To dry the foundation, lay bricks in such a way that there are no gaps and cracks. Use the construction level to get smooth masonry.

- Barbecue walls are neatly and slowly, while the height from the foundation should be at least 70 cm. For pushed the metal doors.

- Think out the recesses for the capacity of the barbecue. It consists of a metal box for wood and top grille for cooking products.

- For the manufacture of chimney and pipes, smokehouse will need a little longer, as it is necessary to make a correctly ventilated hole with a damper for adjusting the flow of smoke.

- When the process of creating the chimney is completed and installed all metal parts, you can start working with barbecue.

Brick smokehouse do it yourself

The place to build a mangala-smoking brick should be located at a permissible distance from residential buildings. Carefully prepare the territory by clearing it from garbage. The depth of the foundation for the smokehouse should be about 40 cm. In the event that you plan to build a large design, then the foundation is pouring the reinforced concrete to 69-70 cm.

For construction, you will need:

- refractory brick;

- construction level, spatulas, hammer, wooden doors;

- lattice;

- metal cover;

- trowel;

- plumb;

- order.

Manufacturing technology:

- First of all, proceed to the manufacture of the chimney, the length of the opening it is closed should be 300 mm, the width is 350 mm, the height is 250 mm. Work with clay red brick. Such material is resistant to temperatures and cracking.

- Masonry on the edge Make a smoking chamber, which should be located at the end of the line. Its height should not be more than 150 cm.

- Before masonry canal, make ditch. Its width should be 550 mm, and the length is 350 mm. Consider the fact that the chamber for firewood should not be above the smoking chamber.

- The masonry should be performed by a clay mixture that does not release toxins.

- The walls of the chimney should be erected by the way "on the edge" on a pre-prepared brick basis. As a result, there should be a wall of 25 cm with brick masonry in 2 rows.

- Channel overlap Perform bricks. This procedure is performed according to the principle of "house", that is, the overlap should not be flat.

- Place the smoke chamber in the last turn so that when installing it, the channel went deep into a maximum of 300 mm.

- Wait for the design to dry and resist a couple of days. Two days later, it is necessary to fall asleep smoothing in 15 cm in terms of the level with a smoking chamber.

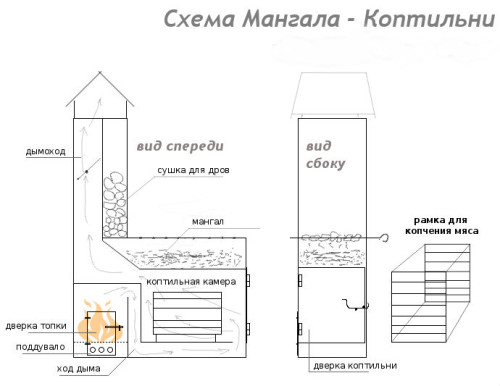

Brick mangal smoke

Thanks to the brick bar, there is a possibility of smoking, meat or fish frying, preparation of grilled products. Combining the mangaal with smokehouse is a very practical solution, because the versatility of this building is simply amazing. Guided by the drawing of the smokehouse from the brick, you can easily make a brand yourself.

Proceedings:

- For a start of a sheet iron, 1 cm thick make a mangala. For welding parts, use gas welding or electric welding. If you do not want to use iron, you can lay out a brazier brick.

- Guided by the Drawing Drawing Drawing of Brick, lay out the basis of the construction and chimney. Dimensions are selected individually.

- If you have no clay to fasten the design, then the earth can be used. It can be wanted between the rows of bricks. Cement for these purposes do not use, since at high temperatures it cracks.

Large smoke-smoking stove of bricks are recommended to do in the form of a house, thus creating a spacious room with a furnace, the smoke from which should penetrate the room. For cold smoking it is necessary to apply a separate smoke generator. Smoking smoke must necessarily have a valve to adjust the streams of smoke and its temperature. If the valve is missing, then the products will coat unevenly.

Advantages of brick smokehouse:

- Reliable in work and durable. Such a smoke can serve you with high-quality work for more than one year.

- Comfortable and safe smoked process. There is no open fire, which means that the wind will not inflate the fire in all directions.

- Cost-effective construction. Expensive wood to use is not necessary. It suffices to apply for smoking sawdust.

- A minimum of carcinogens in the processing of products. smoking products is performed exclusively by smoke from quality wood.

Smoking in a brick smokehouse

Most of the smokehouse is used for the smoking of meat and fish semi-finished products. They can cut pieces or smoke entirely.

- Before the start of smoked meat it is necessary to rub with salt, spices and wait until it starts to give off juice. For some time should be postponed meat. In order to determine whether the meat is ready for smoking, pierce it with a fork. Light projecting fluid would indicate that the product can be sent to the smokehouse. It has to be pre-cut.

- For smoked chicken carcass, it must be cleaned from the inside, cut, washed and singed in the fire. The meat is then coated with spices and leave for 3 days in a cool place. This excerpt is needed the chicken to its meat was tough.

- Smoking of fish can be carried out, both in fresh and salted in the form. As the entire guts and refined pieces. As practice shows, the fish has the best taste if before smoking it prosolit and podvyalit. For grinding larger fish use salt. Before smoking for a few hours to let fish should juice, being in limbo.

The fuel for the smoker can use any wood, but for a good smoke with a pleasant aroma of juniper is best to use chips or alder. Apple and pear branches, walnut and maple are also amiss. You can use a mix of different wood, it will give the product a unique smoked flavor.

Before applying to the wood bark is removed, especially this rule applies to softwood. Wood can be crushed into small pieces, or to saw it into chips. Moistened raw material spread on the bottom of the smoker.

The belief that you can only smoke meat and fish products is wrong, because the smoke treatment exposed as dairy products, and fruits and vegetables. While in the smokehouse product caustic impregnated dense smoke and dehydrated. At this point also disappear bacteria, thereby increasing shelf life of the product.

The homemade brick smokehouse is often the method of hot-smoked. In contrast to the cold, this method is much faster, also has some advantages:

- when smoked products lose moisture minimum;

- any products in the hot smoked smoked smokehouse are juicy.

The smoking process is to treat the products with dense smoke. Gradually, it is necessary to reduce the temperature and density of smoke. Hot smoked time - up to 2.5 hours.

With cold smoke, products are prepared under the influence of cold smoke. Cold smoking takes up to 7 days.