How to pave the pipe under the foundation Construction

The dream of all dacnis - make a country life as comfortable as possible. The device in a house of such benefits of civilization as a washing in the kitchen, a bathroom with a toilet, a bath, a sauna and a pool - a difficult task, but quite real. This requires a water supply system and sewage system. Even if there are no central communications of the wastewater, it is possible to keep the house with the help of modern autonomous systems. Well, if the construction of the house and the installation of communications occurs at the same time, it is possible to think over all the details. The project is made taking into account the supply of pipes, the location of sanitary nodes and observation wells. Provide access to the pipes so that if necessary, it was possible to clean them. The situation is found when you have to conduct outdoor communications in the already available building. With the improvement of the finished home, communication schemes are developing under specific conditions. Homeowner will have to find the optimal solution: how to spend pipes under the foundation the simplest and most reliable way, to prevent the destruction of the foundation, soil drawdowns, breakdowns and strain pipes. Work will require a lot of labor, time, attracting professionals and using special tools and equipment. But the result is worth it.

Content

- Detailed Plan - Successful Success

- How to pave water pipes under the foundation

- How to pave a pipe under the foundation in the way of oblique drilling

- How sewage is arranged

- Caliation Mounting Materials

- Basic principles of installation of the sewage system

- Installation of internal sewage

- Sewage trumpet under the foundation photo

- Installation of external sewage

- How to pave the pipe under the foundation with your own hands

- Comfort in every house

Detailed Plan - Successful Success

In order to competently and efficiently carry out communication, it is necessary to spend time to develop a clear action plan and installation scheme. Redoing harder and more expensive than building. It is not necessary to hope that the decision will come in the installation process. The approximate approach to construction is fraught with serious errors and deposits.

How to pave water pipes under the foundation

Unlike other types of communications, for example, electricity, which is supplied to the house without any special problems anywhere, with the conduct of water supply and sewage is more complicated. There are more large-scale construction work.

To summarize water to the house use steel, galvanized and polymer pipes. More often used PND pipes - low pressure polyethylene. Plastic black tube with blue stripe. Designed for cold water. Optimal pipe cross section for underground laying 32mm, wall thickness from 2 mm. The length of the pipe is equal to the distance from the house to the well with a margin of 50cm.

To lay the pipe dig a trench from the well to a depth of 1.5 to 2m and fed it under the foundation of the structure. The level of soil freezing depends on climatic conditions. Snip there are indicators of the level of labeling of the Earth for different regions. Pipes must lay below the level of soil freezing at 40cm. If the trench is shallow, use the insulation.

Entering the water pipeline to the house is made under the foundation or through the basement. The hole for entering penetrated with a jackhammer or dried by a perforator. The rapid, neat and gentle method of creating holes in the wall, the foundation and overlap is diamond drilling. The pipe is paired through a case (cutting pipe cutting).

The water meter is installed on the place of the insert in the well or after coordination with utilities at the site of entering the pipe to the house. The assembly of the supply of water supply to the house is sealed and insulated.

How to pave a pipe under the foundation in the way of oblique drilling

There are situations where the foundation for entering communications is not possible, for example, thick walls or existence of an extension, and if the foundation is deep and there is a basement, you will have to do too large.

To facilitate the pipe gasket under the foundation and do not dig a deep trench, apply inclined drilling. To the lower edge of the foundation, the inclined well is clogged through which communications are carried out.

The most responsible stage is to correctly calculate the drilling angle to correctly so that the lower end of the shurta coincides with the end of the mortgage pipe, mounted during the construction of the foundation. Earthwood is installed at the desired point, give it the necessary slope with the beam, laid across the trench and drill the shurt.

To preserve the specified direction, the bump must have a long guide pin. Drilling perform slowly, constantly controlling the process to do not deviate from the selected axis. For this shurthed wall, it is posed from time to time. In the finished shurf, the pipe-case, repeating the shape of the well.

Then the metal cable and cable are placed in the pipe. With the help of the cable, it is convenient to drag any hose or cable through the pipe. The rope is tied to the cable so that you can pull it back.

Thus, instead of a deep trench, several meters can be caught only with one inclined drilling.

How sewage is arranged

House sewage is one of the main systems that provide comfortable living conditions.

The sewage system of any complexity consists of three parts:

- Inner circuit - all communications passing in the house.

- Outdoor contour - Communication outside the house.

- Collection - central sewage, well, septic tank, cesspool.

Caliation Mounting Materials

In order for the construction of the sewer system to be clearly on scheduled schedule, it is worth calculating the amount in advance and purchase the necessary materials and tools. For this, a detailed plan of sewage pipes and risers, a horizontal tube, an outer pipe and septica, indicate the dimensions of all sections, connectivity, turns, so that you can accurately calculate the number of pipes, fittings and accessories.

For the outer sewage system, cast iron, metal, asbestos-cement, concrete and plastic types of pipes are used. The most durable - cast iron pipes, but because of the high price and labor-intensive installation in private construction are practically not in demand. Wide use was obtained by polymer pipes: polypropylene (PP), polyethylene (PE) and polyvinyl chloride (PVC). The outer sewer systems are built of orange plastic pipes with a diameter of 110mm. Orange color indicates their purpose - for the outdoor sewage system, in contrast to gray pipes for inner water supply, they are better and durable, resistant to corrosion, destruction and when compliance with the laying technology with the correct bias are not clogged, due to the smooth surface of the inner wall. Maximum depth of occurring such pipes in the ground - 3m.

Two-layer, corrugated outside pipes from polyethylene or polypropylene resistant to high loads and are laid at great depth or under the roadway.

Connect pipes using fittings:

- Taps and couplings with a diameter corresponding to the cross section of pipes.

- Tees suitable styles for branching system.

- Reducers or adapters for docking pipes of different sections.

- Caps for fields for sealing holes.

- Fastening for fixing pipes.

For plumbing work, the sealant is needed - silicone in tubes and a special pistol.

Basic principles of installation of the sewage system

In compiling the sewage and installation plan, the following factors take into account:

View and location of the collection: Central drain,, septic tank, drive, biodecy with aeration.

Mode of operation of the house: year-round or seasonal.

Number of permanent tenants.

Who will mount the sewer system: specialists or on their own.

When designing it is important to comply with a number of mandatory conditions.

- Compact installation in the house of all points of water intake, to create the easiest scheme of the Warning of the War. Simple schemes are always more efficient and cheaper. With the close location of all points of water intake, it is possible to remove the effluent into one common riser. If the kitchen and the bathroom are located in different parts of the house, two risers are installed and two septicis.

- Installation of sewage in the house and on the site is carried out according to sanitary and technical standards and rules. The sewage treatment plant is installed at least 5m from the house, but not more than 15m. If the distance is insufficient, there is a risk of damage to the foundation. If, on the contrary, too large, then the frequent clogging of pipes is possible.

- It is especially important that the septic tank is located at a distance of at least 30m from the well with drinking water. And on the plot with sandy soil and all 50m.

- Septic tying can not be installed next to the neighboring fence. An indent must be at least 2m.

- If the septic model is subject to periodic assessment, provide free passage to cleaning.

- Septic is placed taking into account the slope of the site, below the building level, so the wastewater will be displayed along the sulfur pipe. If, due to the relief of the site, this option is impossible, and the septic tank is on the elevation, the pump is embedded in the system for pumping the effluent into a septic tank.

- When choosing a place for Septic, it is worth paying attention to the structures of the neighboring area: wells, wells and reservoirs to avoid conflicts and trials.

- Sewer pipes are carried out at a certain tilt angle to create a natural flow.

- When developing a project for conducting a highway to sewage treatment facilities, it is recommended that the outer circuit of the sewage is completely direct, without corners and turns. Changing the direction of flow leads to clogging of the sewage system. If no turns do not do without turning, they set observation audit wells in each complex node, a turn with any angle. On small bends, rotary corners of the minimum size are mounted. With the length of the pipeline, more than 15m wells are installed, even if the line is straight. Such measures are needed to maintain the sewage system during blockages.

- To protect against freezing, the pipe from home to the collection is laying deep into the ground. If the septicch is not far from the building, 5-7m, then the pipe from the house is removed at a depth of 1.2 m to achieve an optimal slope of 2-4 degrees (2-4cm per meter). If the septicch is far away, and it is difficult to simultaneously combine a deep laying slope in the soil, then the pipe is packed at the output from the house at a depth 50cm, and be sure to insulate.

- Sewer riser tools revisions, special fitting for system maintenance.

- Hydraulic testing is performed before driving pipes to quickly detect and eliminate possible faults.

Laying outdoor contour and pipes under the foundation video

Installation of internal sewage

First of all, the location of the collection is selected. After that, the place of the output of the pipe of the inner contour from the house is determined. The foundation is done with a hole for the pipe.

The sewer pipeline in the house is mounted so that all the drains flock to the output of the pipe from the foundation. The main element of the internal sewage system is a riser with a diameter of 100mm. The most rational internal sewage scheme is to install the riser to which all pipes are connected from water drain points in the house.

The riser is equipped with revisions (special window with sash) at the level of 1M from the floor. To create ventilation of the sewer system, the upper end of the riser in the form of an exhaust pipe is excreted on the roof of the house.

The method of laying internal sewage depends on the place, height and type of plumbing devices. The main requirement is the observance of the slope for the normal samothek of wastewater. The drain holes of the devices should be above the opening of the main riser. The lower end of the riser is displayed in an underground or base where the horizontal pipeline is paved and combined with a pipe overlooking the foundation into the street.

In place of connecting the riser with a horizontal pipe make a revision well.

Mandatory requirement when installing plumbing is the presence of a water shutter, to protect against the penetration of sewage gases to the room.

For the device of the internal circuit of the sewage, tubes made of polypropylene and cast iron are used. Polypropylene pipes are used more often due to ease of installation and low price. Pig-iron pipes are more durable, durable and expensive, mainly used for buildings with elevated fire and operational requirements.

The internal sewage in the house is carried out in an open way, with the fastening of pipes on the walls, and hidden, when the pipes are packed under the floor and in partitions.

Sewage trumpet under the foundation photo

As a rule, if the sewage diagram is developed at the design stage of the house, the foundation has a tube technological hole. If there is no hole, it is pierced in the ready-made foundation. The hole made exceeds the diameter of the pipe at least 50 mm.

At the site of the transition site from the vertical drain to the horizontal, it is recommended to establish a connection with a smooth output angle. Thus, it is possible to reduce the load from the pressure of the water and pipes incoming under pressure. In the place of docking the pipes of the inner and external sewage, two taps of 135 degrees are installed. Such a device reduces the likelihood of clogging pipe, reduces the degree of wear and noise level in sewage.

Under the building dig a hole according to the sizes of the node. Transitional junction is fixed and equipped with viewing couplings.

To protect against deformation when the house shrink, the pipe passing through the foundation is placed in a metal sleeve, the diameter of which is larger than the diameter of the pipe. To reduce the risk of moving the sewage at the place of the output from the house, the space between the sleeve and the pipe is filled with a mild insulation.

Installation of external sewage

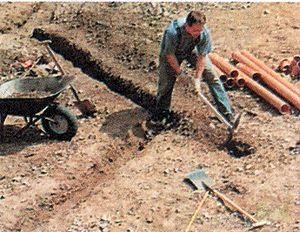

Tresh preparation

Installation of the outer sewage circuit begins with the preparation of the trench, which is digging by manually shovel or using an excavator. The trench makes a sufficient width so that it was possible to freely carry out work on the docking of the pipes, being at the bottom of the trench. For pipes with a diameter to 225mm, the minimum allowable interval from the pipe to the wall of the trench is 20cm, and for larger diameter pipes - 35cm. For pipes with a diameter of 110 mm, a trench is prepared with a width of 0.6 m. The trenches are dried in compliance with the optimal liner of the pipes, 1-2cm for each pipe memory meter of the pipe.

The depth of sewage laying is not normalized. The level of pipelines depends on the depth of the primer of the soil in this region. SNiP parameters are advisory and varied depending on the level of groundwater and other facilities of the area. The minimum depth of laying sewer pipes is 0.5 m from the surface of the Earth. The bottom of the furrow is leveled, cleaned from large stones, dense shut-off blocks.

After leveling, the bottom is thoroughly tamped and pillow pillow from sand or gravel with a height of 10-15 cm. Laying the shock absorption pillow under the pipe is required for all types of soil. This is a subfold of gravel with a caliber of no more than 20 mm or sand. The sand or gravel pillow is aligned before laying pipes, and the plot for 2m to the observation well and the connection site of the pipeline with the inlet pipe is also sealing. Under the conversion of pipes, small recesses make.

Sometimes the type of soil is found, which forms a too smooth surface of the trench bottom. In such cases, a small groove is digging in the width of the pipe base and fill in a softer soil.

Laying outdoor sewer pipes

To assembling the outer sewage is proceed from the foundation. If the output of the pipe from the house was laid during the construction of the foundation, then the first outer tube is put on to the smooth end of the exit pipe internal sewage. If there is no pipe in the foundation, then the pipe is inserted under the foundation or through it the process hole is drilled by the diamond drilling method.

The sewer pipes are placed by the fools against the slope into the trench prepared in advance. Docking pipes are carried out at the bottom of the trench. It is performed in the following order:

- Cleaning from the contamination of the inner surface of the socket of one pipe and the smooth surface of another pipe.

- Lubrication with silicone or liquid soap of a smooth end of the inserted pipe and a rubber sealing ring in the Ranker.

- Pipe connection is one to another. The docking of the pipes is performed manually until it stops, unlike the pipes of the inner contour, where it is impossible to connect pipes to the stop due to the temperature expansion of the pipes. When assembling the pipeline, one tube is inserted into the nonsense of the next one. In order for this connection to be durable, measure the depth of entry and set a mark. Eliminates the task using special tools for mounting the pipeline.

Slide and turning of the sewage pipeline

The slope of the pipes with a diameter of 110mm is 2 cm to 1m. Such a bias ensures smooth flow of drain, together with solid particles and prevents the appearance of blockages. With a smaller slope, the promotion of water will slow down, and with larger water will merge faster than solid fractions, which will result in the drain in the highway.

For turns of the sewage pipeline, smooth taps are used for the outer circuit (15, 30, 45 degrees). With the length of the sewage route, more than 15m on each turn provide a revision setting. Sewer pipes are carried out to the cleaning installation. The septic is soldered with a gray nozzle, through which the outer pipeline is connected to the collector camera using the rubber seal.

Heat insulation of sewage pipes

The need for insulation of sewage pipes occurs when the pipeline runs above the depth of the primer of the soil or at the outlet of the foundation. For insulation of the external sewage pipe, modern thermal insulation materials, stainflex or power flows, isopaip, foamed polyethylene are used.

The pipe is wrapped with insulation and placed in the asbestos-cement pipe of the larger diameter. To protect the sewage system from freezing in regions with strong pipes, the pipes are supplied with a heating electrocabel with temperature sensors, which will ensure uniform heating of the pipe.

Flipping trench

It would seem that here is special - to fall asleep pit? But everything is not so easy! The flow of trench with sewage pipes is carried out in accordance with the rules for carrying out excavation works in the device of waterproofing, water supply, fastening the walls of trenches and the construction of self-sealing sewage drains, regulated by SNiP.

This means that only after the completion of thermal insulation measures, the control measurement of the pipes, the installation of wells and carrying out all hydraulic tests on the tightness and strength of the pipeline compounds are embarking on the back of the pipes.

The filling of pipes make gradually: first sand on the sides of the pipe with layers of 5 cm to a height of 30cm with a seal of each layer on the side of the pipe. Then pour the sand layer 15cm above the pipe. From above, the sand pipe is impossible. After drowned with sand in the trench, the electrocaban is placed in the protective corrugation for powering the selection.

The final backflection is made with an earlier soil. To prevent damage to the laid pipeline, carefully check that there are no stones, solid lumps, frozen land in the soil to fallinate the trenches. The flow of the trench is made by uniform layers, 10 cm for sandy soil and 5 cm for clay. In cases where the soil occurred from the trench is not suitable for snowing, use sand. The soil is saturated with a slide to compensate for the subsequent shrinkage.

How to pave the pipe under the foundation with your own hands

Communication systems of the building are complex engineering structures. However, the owners of small country houses can carry out a simple scheme of water supply and sewage with their own hands in the presence of desire, time and experience of construction work.

If the sewage system is already there, but requires repair, more rational will completely dismantle the worn pipes and lay new ones. In fact, the overhaul will take less time than the latling of holes, and, most importantly, will extend the life of the system.

First of all, make the placement of the location of the sewer pipes from the house and the location of the waste well. Measure the estimated length of the entire sewer pipeline.

In the house reveal the floors from the place of drain until the sewer pipe is out. Trench under the pipes dig up to the bottom edge of the foundation. The minimum depth of the sewer pipe under the foundation is 0.9 m. The foundation is pierced with a simple well in the ground with scrap or remedies. To do this, outside the foundation on the street dig a soil to the desired depth. Put a bayonet shovel under the foundation.

From the inside of the house with a sapper or bayonet shovel spend a counter-shoe. Scramph falls the ground from the shurph into the tunnel. Earth is more convenient to remove from the street. Expand the opening of the pipe, respectively. As a sleeve (case) for water pipes and sewer pipes, the D100 iron pipe is used with a smooth tap.

The removal will be under the foundation with the output outside 20-30cm, and the pipe is directed up into the house. To the tube through the velocked holes tie a strong rope in the form of a loop. The removal is closed with a cloth or package. The pipe is better to lay together: one from the street serves, the other in the house clings the sturdy metal crochet behind the loop and drags the pipe into the house. It turned out a protective chalise case for the future pipe. The pit is buried and sweat. If the soil is heavy, make a submissions from the sand so as not to sell the pipe.

For normal sewage operation, a slope is required at least 2-5 degrees. Therefore, the trench from the house to the collection is gradually plugged, so that the flow of the runoff into the sewage pit is at a depth of 1.5 m, and the well itself had a depth of 3m. Such a level reliably guarantees the protection of the system from the freezing.

At the bottom of the trench, the sand layer is about 15 cm. Then places plastic pipes, they should fit tightly to the sandy pillow. For the uniform load of the soil, the sand layer is poured over the pipe - 15-20 cm.

On a long pipeline every 5m, revision wells make. To do this, the tutor is inserted into the pipe and remove the vertical pipe of the pipe up. To do not penetrate the cold through the pipe, they put the plug from the heat insulation material. Plastic tubes in the joints of the joints are sealed with rubber cuffs. For greater strength, the compound additionally use silicone sealant.

Comfort in every house

A private house, unlike the apartment, requires more attention, strength and expenses from its owners. With the improvement of the house, first of all, it is necessary to make a detailed plan, acquire building materials of good quality and invite experienced specialists. All the problems and difficulties of construction will quickly rise, and a cozy house, convenient for staying at any time of the year, will please more than one generation of its owners.