Installation of a gas boiler with your own hands Climate

Gas boilers are designed to obtain and transmit thermal energy to the coolant. Without such installations, heating at home can be said, it is impossible. It is the gas boilers today are the most common. Popularity they deserve due to their reliability and economy. The advantages and disadvantages of gas boilers, as well as their features of their installation, will be considered a bit more details.

Content

Advantages and disadvantages

Of the advantages, first of all, it is worth noting the following:

- These installations allow you to heat the room fairly large area.

- In addition, the efficiency of these boilers is quite high. At the same time, the price of fuel, i.e. Gas is quite low.

- Of the advantages, it is also worth noting the ease of installation of the gas boiler with their own hands, which allows you to save a considerable amount of funds.

- In addition, such installations are compact, thanks to which they are pretty organically fit into the dwelling interior.

- It is also worth noting that there is no need to follow the fuel supply. After all, it is submitted continuously. If the fuel for some reason ceases to do, then this will be immediately reported by the corresponding sensors. At the same time, the automatic ignition system will work, which will again lit the burner.

- The advantage is still the fact that these boilers are easy to operate, have a high efficiency and can be operated for a long time.

We now turn to disadvantages:

- First of all, the installation of such equipment requires compliance with the set of conditions. At the same time, it will have to make up all the necessary documentation that is required to submit to Gaztekhnadzor.

- If there is a decrease in pressure in the system of the total gas pipeline, the efficiency of equipment in general will be reduced. The same thing happens when the burner wear.

- When the gas boiler is running, spent substances are formed, for the output of which it is necessary to install an extract or chimney. Therefore, the room itself should be well ventilated with a separate exit to the street. These requirements are especially important for aggregates equipped with atmospheric burners.

- If the area is less than 100 square meters. m, it is better to use another type of boiler. The fact is that it is economically inexpedient and just dangerous. In addition, it is required to install the equipment that will control the gas leakage, and these are additional costs.

Below will consider the features of this type of equipment and how to connect the gas boiler.

Classification of boilers

Gas heating boilers are accepted for:

- wall-mounted

- outdoor.

Moreover, if there are already several dozen years old, the wall types of such equipment appeared relatively recently. Despite this, they have already deserved considerable popularity. In addition, in terms of cost, they are much cheaper than boilers outdoor. Wall-mounted variants of gas units are equipped with not only with such mandatory parts such as a burner, heat exchanger and control panel, but they also have other important elements, such as an expansion tank, pressure gauge, thermometer, circulating applications, and security control. Therefore, such installations are sometimes called mini-boiler.

Exhaust gases can be eliminated in a natural way (due to the thrust generated by air flow) is either forced (by means of a built-in fan). The second option involves the presence of a coaxial chimney. At the same time, to support the burning of the boiler, the influx of fresh air is not required. The aggregates with such a traction appeared relatively recently.

As for the type of ignition, the wall boilers in this regard can be:

- with electric ignition,

- with Piezorozhig.

The first option is considered more economical. In addition, such aggregates in case of small failures will automatically resume work. But the boilers with Piezorozhig will need to be turned on manually at any failures. Such equipment can be equipped with a conventional and modulation burner. The second option is more economical and practical, because such a burner allows you to adjust power depending on the need.

Most often, wall types of gas boilers are equipped with all equipment that guarantees its safe operation. In particular, there is a fire sensor for them. When the flame hit, it is capable of turning off the fuel supply. A blocking thermostat is also installed, which suspends the operation of the installation in the event of an emergency temperature increase. There is still a device that turns off the equipment in the event of a power off.

As for floor boilers, such devices are successfully applied for quite a long time. And for a long time they were not somehow changed. For example, cast iron or steel is used as the heat exchanger material. Both options have their own advantages and disadvantages. For example, heat exchangers made of cast iron are less susceptible to corrosion than steel, but at the same time they are more fragile. Therefore, they have a higher risk of small cracks during transportation and installation.

In addition, when using hard water in cast iron boilers, the heat exchanger is gradually collapsed. Steel units have a smaller weight, but if the rules of operation will not be followed, then corrosion appears on the surface of the heat exchanger. Outdoor gas boilers can have two types of burners - atmospheric and upgraded. The first option is less than cheaper and noise from them, but they have a relatively small power - from 10 to 70 kW. The second option is more expensive and has a higher efficiency. At the same time, the power of such burners is measured in thousands of kW, which gives a large selection for consumers. It is worth noting that if the atmospheric burner is part of the gas unit, then the upgrade must be purchased separately.

The uninterrupted functioning of gas boilers is highly dependent on the operation of the power grid. Therefore, manufacturers try to take into account the issue of interruptions in power supply.

How to choose a gas boiler

Any home owner wants to acquire high-quality and reliable equipment. And the first one needs to decide when choosing a gas boiler is its power. In the selection of power, it is usually based on the value of the energy intensity of the heating system. If the boiler is needed not only for heating, but also for heating water, it is recommended to make a choice in favor of a wall gas boiler. This option is inexpensive and easily mounted.

If you do not want to carry out maintenance every year, it is possible to give preference to the unit outdoor type. Such equipment is more expensive, but does not require inspection every year unlike a wall gas boiler.

As for the manufacturers' companies, it is worth saying that domestic aggregates today are practically not inferior, and sometimes exceed overseas analogs. In addition, it is much cheaper. In any case, the choice remains yours.

How to install a gas boiler

Installation of outdoor aggregate

Procedure for installation work:

- You should start with the preparation of the place where the equipment will be installed. Remember that the floor boilers will decently weigh, therefore the foundation for them should be quite strong. Perhaps even have to fill the screed. The floor itself must be performed only from refractory materials. If this is not the case, then the coating is necessary to install hollow concrete blocks with a height of 110 mm, which then need to be covered with sheets of metal.

- When installing the gas boiler, it is necessary to consider the fact that the distance between the aggregate itself and the wall should be at least 100-110 mm. The wall coating itself should be from non-combustible materials. If required, it is allowed to move the unit closely. Only the wall in this case will need to be covered with refractory material. For this, the steel sheet is placed on the formation of asbestos, the thickness of which is at least 4 mm.

- It is important that the insulation overlap around the perimeter dimensions of the boiler housing at least 100 mm. The convex parts of the reinforcement should be from the wall at a distance of at least 1 m.

- When the base is prepared, then the equipment itself must be placed on it as much as possible. It is possible to check the construction level. If there is a need, it is possible to put a solid non-flammable material for the alignment under the legs of the unit.

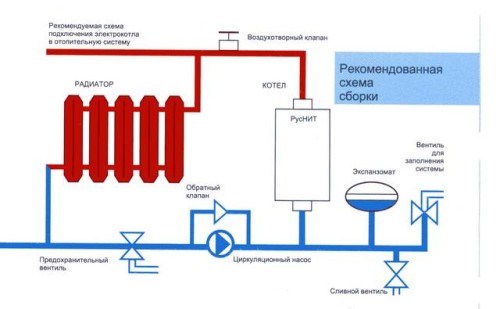

- After alignment, the boiler can already be connected to the heating system and chimney. So that the heat exchanger is not clogged too quickly, a hard cleaning filter is mounted before entering the return highway. If the design of the boiler is a dual circuit, the unit still needs to be connected to a cold water pipeline.

The installation of the gas boiler is recommended that, if necessary, it could be easily dismantled if necessary. All subordinated pipelines must be mounted locking valves. If the unit is required in the future to dismantle, then the valves are simply closed, with the water in the most heating system you do not need to merge.

Installing a wall gas boiler

The wall-mounted type unit is suitable in the case when the equipment does not require high power, and there is a bit of free area to install the boiler. Such equipment is successfully used to heat the water, as well as the heat source for the heating system in high-rise buildings. If there are several gas devices, the installation of the gas boiler in the house should be performed so that between the aggregate itself and other gas equipment it was at least 220 mm.

The permissible distance to the wall depends on the model and power of the boiler. On average, it ranges from 300 to 500 mm. In the opening between the walls of the boiler is better not to put. The same applies to the places close to the window. In any case, the power supply should be closely located.

When assembling equipment at the factory, extraneous particles from which it is required to get rid of the installation is required before on-installation. To do this, you can rinse all pipes and system with water. Then the wall-mounted type assemblies is attached to special planks. On the nozzles, there are usually plugs that need to be removed before connecting the gas boiler with your own hands.

General rules for installing a gas boiler

- For an outdoor gas boiler requires a separate room with an area of \u200b\u200bat least 4 square meters. At the same time, the height of the ceiling here should be at least 2.6 m.

- An important requirement: walls, floor and ceiling of the room in which the unit will be located, should not be separated by combustible materials.

- In addition, in the room where gas equipment is installed, there should be no falsefield or a raised-brake. The room should have a separate door leading to the street as well as the window.

- In order for the premises to be ventilated, which is also a mandatory requirement, through the purity is made. Its section depends mainly on the power of the equipment.

- For all types of gas boilers, the installation of a separate gas plant is required. Ventilation channels for this purpose are prohibited, since there is a high risk of getting harmful substances in residential rooms. The horizontal part of the gas plant in length should not exceed 2.7 m. In this case, there should be no more than three angles of rotation.

- According to the gas boiler scheme, there are some important requirements for the output of the gas plant. So, from the ridge of the roof, it should be located at an altitude of at least 1 m. In this case, its position should be strictly vertical.

- As for the chimney itself, it must be made of solid materials with resistance to temperature surcharges and chemicals. In very rare cases, it is allowed to use layered materials for this purpose.

- If the boiler equipment is required to heat the room, then gas service employees are obliged to check the condition of the central heating system. In particular, the slope of pipes must be checked. The permissible value of the slope is not more than 4.9 mm.

- At the highest point of the system, you must install the air faucet or the expansion tank. In addition, the heating system must withstand the strength test with a pressure of 1.8 atmospheres.

- In some cases, the gas unit is prohibited to be installed. For example, if you live in a multi-storey building, in which there is no gas highway. If there is a false-brake in the kitchen, which you do not want to clean, then the gas boiler will not suit you either.

- Installations for heating cannot be installed in an unsuccessful apartment. Maximum for which you can count on, this is an aggregate for water heating. The fact is that the room in which the boiler will be installed, we need redevelopment, and only the owner of the apartment is entitled to.

Gas boiler: photo