How to put a blocking Plot.

The most popular material for the creation of garden tracks and the arrangement of the indentation area is a paving. She almost displaced the familiar asphalt. Laying pavers - the best way to create an original pedestrian zone. To do this, use the tile of different colors and forms from which patterns are combined.

Content

Styling technology blocks

Specialized brigades are labeled paving slaves. The price depends on the scope of work (diluted area), on the base, on the method of laying and on the complexity of the pattern. Possible laying of pavers with their own hands. The technology of this process consists of several stages.

- The platform on which the tile will be laid must prepare. The territory is exempt from trees and bushes, the turf and the top layer of the soil is removed, after which the Earth needs to raise.

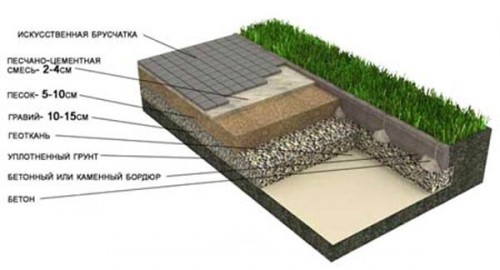

- We prepare the "litter": the first layer must withstand the load and therefore it is suitable from a compacted mixture of gravel and rubble. At the same time, it is necessary to observe the minimum angle of the slope of 1.5-2% of the middle to the edges. The minimum thickness of the carrier layer is 100 mm.

- At the edges of the site, a border is installed. To do this, it is necessary to prepare a deepening in the soil in the form of a furrow, on the bottom of which you need to pour sand. Calculate the depth of the furrow so that the border subsequently was flush with the front side of the paving or slightly lower (for the drain water flow). In the corners of the rectangular platform, two borders are installed, and the cord is tensioning between them, which will serve as a reference to further work.

- On top of the prepared platform, the following layer of 30 mm thick is poured - from coarse river sand (fraction up to 5 mm).

- Staying paving slabs (sidewalk tiles) from the border begins: the first rows are placed, orienting the edges of the tile in the direction of specially stretched threads. The seams between the pavement are filled with sand: it is necessary in order for it to move.

- After the laying of the paving slaves will be fully completed, all seams are replenished with sand. With the help of vibrator, the tile is aligned, after which the seams are once again compacted with sand.

In order for the laying of clinker pavements to be performed qualitatively, it is necessary to prepare a basis in accordance with the construction regulations. The main thing is to strictly withstand the necessary thickness of all layers of "bedding". If the pavement lays along the walls of the house, a bias is needed away from it. This will provide the necessary drainage. Laying blocks in winter is not produced: work should be performed in the warm season. Otherwise moisture, freezing in a mixture with sand, will expand and destroy the bridge.

Requirements for stacking paving

It is necessary to know how to lay a pavement depending on the intended load. For pedestrian tracks, it is enough to create a preparatory layer from 50 to 150 mm sand. After the mounds, it is moisturized and tamped. It is important to observe the optimal proportion of sand and water at moisture: 1 m² of the territory should not have more than 10 liters.

After installation, the border of the paving slave is stacked and caught up at the place with a rubber image. Excess sand should be removed by the jet of water from the watering hose. Such laying of pavers (photos of some stages of the process is attached) is the most technologically simple.

Laying paving slats on concrete base

This method is used if the vehicle movement will be organized on the ground covering. It is also required for weak, swampy soils. It is necessary to prepare a solid base before laying a paving, which can serve as concrete. To create a pavement coating with such a base, you must perform the following:

- After preparation of the site (described above), formwork is made from boards or sheets of plywood: it is attached to the stakes, driven into the ground at a distance of no more than meter from each other. For alignment, a stretched cord is used.

- The playground is falling asleep with a layer of gravel of the middle fraction, which is tamped. The crushed stone layer is about 100 mm.

- Concrete pouring is performed. In the middle layer it is desirable to lay a reinforcing grid. Concrete fill thickness - about 30 mm.

- Every 2.5 - 3 m are needed inserts from boards to compensate for soil movements.

- In order for the concrete to frozen evenly and not formed cracks, the fill must be covered with a plastic film.

- After 28 days, when the concrete completely curses, proceed to laying the paving slabs.

- The seams between the tiles are filled with cement-sandy solution.

- The pavement is washed with watering can be washed with a cement mixture in the seams not damaged. After a couple of days, the tile should be reused with a strong jet of water.

The dimensions of the diligent platform (width of the track) must be selected so that the tile does not need to be cut. But if necessary - this is done with the help of a grinder with a diamond circle.

Laying on a rubberized basis

With this method, a dry sandy mixture is used (the proportion with cement is 1: 6). It is poured on the aligned base, covered with a layer of rubble with a thickness of 100 - 150 mm. Borders are installed on the mixture of M-100 brand. For greater rigidity, the use of reinforcing grid is allowed. The tile is stacked so that the seams are suitable between individual elements: they are necessary to compensate for seasonal grounds of the soil.

Laming stacked in a certain order. Most often used "Christmas tree", but if desired, any pattern is possible, for which the tile of different colors and forms can be used. If necessary, a special color grout is used - a fugue consisting of sand, cement and pigment additive. A paved surface is leveled with a rubber image, and then the platform is abundantly watered with water. After the seams are filled with a solution, it is necessary to wash off its traces from the surface with the help of watering.