Choose material for garden tracks Plot

It is difficult to imagine a well-kept garden without neat tracks. Garden tracks primarily serve for convenient movement on the site, transportation of goods on the trolley, provide access to beds and flower beds. In addition, they give the garden with a neat appearance, emphasize his stylistics, separated on the zones. Today, when the "Garden Industry" is growing rapidly, the construction of garden tracks is not a problem. You can invite an experienced master to laying the track, but if you wish it easy to do with your own hands. Materials for coating garden tracks Mass: natural and artificial, purchased and fading, economical and more expensive. General requirement for all materials: strength, moisture and frost resistance, environmental friendliness, durability, facilities for cleaning. The covering of the track should be a harmonious component of garden design. Using computer programs on landscape design, you can simulate the country area and make a visual planning scheme of garden "routes" and choose the optimal version of the road surface.

Content

- How to choose the road material

- Types of garden tracks

- Hard tracks

- Soft tracks

- Combined tracks

- Special tracks

- General technological rules for the construction of a garden path

- Garden track from tile do it yourself

- Putting garden tracks homemade concrete slabs

- Garden tracks from girlfriend materials do it yourself

- Wooden garden track with their own hands

- Garden stone stone with their own hands

- Garden track made of pebbles do it yourself

- Garden tracks from round stones

- Borders

- Successful tracks!

How to choose the road material

By functional load

- When buying a material for garden tracks take into account the estimated functional load.

- In places of frequent walking places dense whole paving.

- Coverning pathways should be particularly reliable and durable.

- For low-used paths, sufficiently bulk materials: sand, pebbles.

According to the features of the garden landscape

The coating for garden tracks is selected taking into account the relief of the plot, garden style and features of the architecture of the house. It is not necessary to do the same paths on the entire site. Near the house, the adjacent playground and tracks can be laid out of the paving, and the paths in the depths of the garden from gravel and rubble. A smooth transition from one type of coating to another is achieved by combining or repetition of elements in the connection places.

Types of garden tracks

Depending on the type of material and technological features of the styling, the following types of garden tracks distinguish:

- tough

- soft

- combined

- special.

Hard tracks

Hard coating include: concrete, natural and artificial stone, paving slabs, wood, clinker brick.

Garden tracks from wood

Quite often for laying garden tracks is used wood. The most suitable breeding tree for paving is the larch. Its advantages include high strength, moisture resistance, beautiful pattern and color of wood, pleasant resin smell. Wood tracks are usually placed from transverse sleeps, beaten in soil or solid boards. For the country area with a swimming pool, there are paths from wide wooden boards.

Wooden coating - natural material, pleasant to walk, appropriate in any garden. There are bulk wooden tracks from wood sawdust or mulch. The mound from mulch and sawdust sends and shifts when walking. The tracks of this type are paved in places with low passability. They require regular subtype. The main disadvantage of the wooden coating is exposure to rotting and briefness.

Decing Sad parquet

Garden parquet, Decong or Antislip - a new interesting material of garden coatings. It uses natural solid wood.

Garden parquet has a form of sections of a rectangular or square shape made of wooden planks. Planks are attached parallel to each other or with a specific pattern. Standard dimensions 30x50 and 50x50 cm.

Sections of the garden parquet are connected in the styling process. They are fixed on special supports. Different height of support allows tracks to repeat the relief of the site or smooth out the drops of the ground level. In the garden parquet there are ventilation slots up to 8 mm wide. Sections of the garden parquet are tough and soft fastening. Hard parquet is completely wooden, and in soft there is a plastic lattice substrate with fasteners. Installation of garden parquet is simply made and quickly.

Advantages of garden parquet:

- environmental safety material

- durability (up to 50 years),

- the ability to maintain heat

- rapid dryness

- resistance to moisture and rotting,

- anti-slip profile

- strength,

- easy installation,

- ease of care

- variety of drawings.

The surface for laying a garden parquet must be carefully aligned and tamped.

There are various options for the base under the garden Decing:

- concrete screed with drains,

- wooden lags covered in Gravel,

- sand-gravel pillow,

- sealing land treated from grass growth.

Properly prepared foundation will ensure reliable placement of garden parquet and high-quality drainage.

Garden parquet requires care, it is washed with water, severe pollution is brushed. At the end of the season, the parquet is dismantled and stored in a dry room until the next spring.

To protect against fading, parquet are covered with special oil twice a year. This will allow you to even more extend the life and maintain an attractive appearance of Decing.

Garden tracks from stone

The stone is traditionally used for the construction of garden tracks. This material is on the century. It works organically in any garden. Thanks to natural origin, durability, beauty, variety of breeds and forms, the stone is widely used in the arrangement of the garden landscape.

For paving tracks in the garden, various rocks are used. The texture of the stone coating can be rude, rough and smooth to shine. The range of colors and shades is the most diverse: gray, dark red, black, greenish-gray. The main shortcomings of natural stone - its high cost and heavy weight. The most expensive breeds are granite, basalt, marble and porphyr.

Cheap species include limestone and sandstone. In winter, ice crust is formed on the granite and marble. To get rid of ice, under the stone coating, the heating system like a warm floor is mounted.

Processed and untreated stone are used for the paving garden paths. Without processing, sandstone is used, limestone, dolomite, quartzite, slate, gneiss, granite. They are used in the form of a tummy and crumbs. The processing are subjected to rocks: quartzite, gabbro, basalt, granite, diabases that are used in the crusket and sawmill. Common material for tracks are different types of pebbles: marine, river and lake. There are even mosaic paths from multi-colored chopped pebbles on a special tissue basis.

Granite, diabases, gabbro and basalt belong to the magmatic rocks and are highly strength. These types of stone are used for the manufacture of paving stones and plates.

Dolomite, limestone, sandstone and shale are sedimentary rocks. With the arrangement of garden tracks, they are used in the form of plates with a thickness of at least 4 cm. These breeds have a porous structure. Limestone and tuff absorb moisture. A coating of such a stone is desirable to process the special composition of water repellent every 3 years.

Concrete bridge stone

An economical alternative to a natural stone blocking is a concrete bridge stone. It is produced several sizes and different shapes, rectangular and rounded. Concrete bridge stone is most suitable for tracks with transport loads.

Paving tile

For the production of modern paving slabs, cement-sand composition is used with the addition of dyes. Tile is comparable for strength with natural stone. Paving tile has a thickness of 45-80 mm. According to the production technology, the tile is vibrating and vibropressed. For the front entrances, road trains are preferable to a thinner and durable vibro tile, pedestrian walkways are laying out the vibropressed tiles.

The paving the tile coating is performed by different ways: "Dressing", "Fir-tree", "Lestenka". There is a method of laying "aimbel" when wide intercine gaps are filled with lawn grass or gravel, crumb, sand.

Paving tile is concrete and ceramic. Ceramic tiles are better to choose with a rough surface to avoid sliding. There is a ceramic tile, imitating natural stone, "ceramic granite" or a coated with icing of different colors.

At the time of buying paving slabs in Moscow The following characteristics should be taken:

- Frost resistance (200-300 cycles). One cycle according to GOST means holding the prototype tile at temperatures from -20 to + 200C. In winter, the pavement tile passes approximately 5 cycles. Thus, the service life is 40-50 years.

- Water absorption (3-6%). The smaller this parameter, the better, since the water freezing inside the tile destroys it.

- Compressive strength (400-1000 kg / cm2). This is a load indicator that the tile is capable of withstanding. For garden tracks, a tile is quite suitable with a smaller compression strength.

- Bending strength (40-150 kg / cm2). It characterizes the strength of the tile located at an angle.

For garden tracks, paving tiles and figured cells of paving diverse geometric shapes are used. In addition to the usual rectangular paving, the tile is produced in the form of a rhombus, honeycomb, coils and other more complex shapes. There are edge modules of paving slabs with a hidden side for laying close to the curb or wall of the building. It is very convenient, as it eliminates the need to cut the tile. There is a paving tile of the most diverse color scheme. Tile is completely colored and superficially painted. The paint in the form of the top layer is continuous and quickly erased.

The paving slabs are distinguished by durability, strength, frost resistance, it is suitable for access and pedestrian tracks. Tile coating moderately heats up in the sun. Tales and rainwater quickly goes into the interputric gaps, not leaving the puddle on the track. When compliance with the laying technology, the tile coating does not settle and does not form a depression.

Clinker brick

Clinker brick is designed specifically for paving tracks. It is produced a variety of shape (tile, ordinary or slit brick). This material practically does not absorb moisture, is distinguished by increased abrasion strength, has an original color.

Clinker brick lay on top of the pebble or rubble on a concrete solution with a layer of 2-2.5 cm. The seams between the bricks are filled with a sand-cement mixture in the ratio of 1: 4. Slital clinker brick is recommended to lay on a sandy-gravel pillow. The gaps fill with fertile soil and sowing grass. Brick is one of the most durable materials for garden tracks. He is strong, frost-resistant and does not fade in the sun. With the help of different methods of brickwork, you can lay out geometric patterns in the form of a Christmas tree, braid, bricks and perpendicular rows.

Plastic

Garden tracks from plastic - a simple and economical option for country sites. Most often, the ranks of 30x30 cm ranks are sold, which are easily and quickly bonded with each other. Recently, paving slabs from plastic appeared. Its installation does not represent complexity: the tile is simply stuck in the ground, which is especially convenient for quick laying of temporary tracks.

Soft tracks

Funny garden tracks

For laying soft tracks, a variety of bulk materials are used: crushed stone, gravel, explosion, sand, wood bark, sawdust.

For garden tracks, loose materials of the fraction of up to 2 cm are used. The smaller the fraction, the more convenient the coverage for walking. The bulk tracks look especially good with plants planted along them. The bulk tracks can be homogeneous and monotonous, and you can create a mosaic from multi-colored stone crumb, discraining, pebbles, wood crust.

A bulk coating of garden tracks is considered the easiest and inexpensive. The prepared base of the track is placed in a mission in several techniques with thin layers, followed by a rubbing of each layer with a roller or vibratory. For the obstacle to germination, geotextiles or a film for mulching are placed on the base.

Environmentally friendly and pleasant walking paths from tree bark. When settling crust layer, it periodically spiked. Relatively recently, for bulk steel tracks applied shell pine nuts. Pine volatile purified and disinfected air. After two years spent shell used for fertilizer and mulch. A disadvantage of such a coating is a wind blowing for ease of material.

herbal track

The most time-consuming and unpredictable material for paths in the garden. Such herbal coating must be resistant to trampling and shade tolerance when the track extends in a shady place. Caring for the "green" track is the same as for the lawn. Garden path with grass at the frequent use of quick trampling, so they do quite broad.

Gravel

Gravel refers to low-cost and available materials. It is easy to fit. Its disadvantages are: the noise when walking, sprawling to the side and the difficulty of cleaning leaves and snow.

expanded clay gravel

Expanded clay gravel is a relatively new material to cover the garden paths. Its undoubted advantages are: light weight, environmental friendliness, low cost. LECA is obtained by heat treatment of fusible argillaceous rocks. Clay gravel fraction can be from 20 to 40 mm. Expanded clay gravel has a low water absorption of 8-10%, frost resistance, thermal insulation.

combined track

These tracks are a combination of fragments of the hard and soft coatings.

Special tracks

Special tracks are laid out materials made complex technological process.

architectural concrete

Decorative concrete called monolithic coating of concrete with special reinforcing additive of polypropylene fibers. Decorative concrete is produced directly at the place of installation. The thickness of the concrete layer depends on the degree of load on the coating. For pedestrian areas, at least 50 mm, for access - 100 mm and more.

For the manufacture of decorative concrete using special dyes, impregnating sealants. The result is a surface that simulates a variety of materials: stone blocks, brick, flagstone, wooden flooring. Decorative concrete is characterized by a very low water absorption (0.5%), frost resistance (250 cycles) and resistance to abrasion. Decorative covering of concrete is not subject to the occurrence of thermal and shrinkage cracks.

The surface of such a track does not slide after the rain. Decorative concrete is not destroyed by the action of aggressive chemicals. The dye includes granite crumb and quartz sand. Thanks to the chemical composition, the dye penetrates into the structure of concrete, forming a durable composite. For finishing finishes, sealants are used that create a solid polymer film.

A garden track made of decorative concrete is beautiful, durable. It can be stacked over the old concrete base.

Lawn lattices

Special coating include cellular panels (lawn grilles). They are made from polyethylene and large density plastics. The lattices put on the prepared base, fill with fertile soil and sowned by lawn grass. The lawn paths with great mechanical strength are obtained. They are able to withstand the load up to 200 tons / m2 and can be used for parking or accession.

Asphalt

Asphalt coating is more suitable for tracks with intensive load. They do not differ at attractiveness, so they are laid in low-rise garden places, for example, towards the Hozblock. Asphalt for garden tracks happens black, green and red. The asphalting of the tracks is carried out in warm dry weather on a specially prepared durable surface.

Tennisitis

Tennisitis - new material for covering tracks was originally used on tennis courts. Tennisite has red or yellow. It includes clay, filler of brick ceramic crumb, lime. Clay fractions absorb water and swell, which contributes to the formation of a solid dense structure and prevents the appearance of dust.

Brick crumb has durability. It consists of granules without sharp edges. Tennisitis passes water and holds the humidity, which prevents the surface cracking. Tennisite coating is distinguished by relative softness, injuries and environmentalities.

The coating density of tennisite 1.1 t per m / cube. The optimal is considered the thickness of the layer 5-6 cm, taking into account the sedimentation initially pour a layer with a thickness of 10-11 cm. Tennisit consumption is 0.1 m / cube. per 1 m / sq. As a base for tennisite, a crushed stone-sand mixture or a sandy-gravel mixture with a fraction is 0-40 mm.

The depth of the trench under the base is 100 mm, the bottom is covered with geotextiles, the base is poured and seal a vibratory bar.

A geotextile is once again laid between the rubble-sandy layer and tennisite. For two weeks, the coating occurs. After that, on it can be walking. Tennisitis is combined with a stone or tiled border. Garden paths covered with tennisite are easy to maintain and repair. If necessary, the material is plucked once a year and the surface is sealing. In dry weather, the tracks from tennisite are watered with water from the hose with a sprayer so that the coating does not crack and dust. Sold material in bags of 50 kg or by weight.

General technological rules for the construction of a garden path

With the arrangement of garden tracks, the preparation of a qualitative basis is important. For a track on a clay soil with an estimated heavy load, a depth is required at least 50 cm and a sandy pillow with a thickness of 30 cm. For the pedestrian tracks on heavy soil, a sufficiently sand-gravel base with a thickness of 30 cm, in which the sand layer is 15 cm. Each gravel layer, Rubble and sand are sealing and spilled by water.

The bottom of the trench is tamped and closed with geotextiles. After sealing the bottom, geotextiles spread. Between the sandy and gravel layers also laid geotextiles, which increases the strength of the foundation and the life of its operation. This material was designed specifically for road construction in the regions of permafrost. Isolating the layers of soil and pillows, geotextile prevents the sheeping of sand and sending a gravel and crushed stone pillow to the ground. He excludes the germination of weeds and misses the water well.

When paving the tracks of stone or tile, the base is used by the sand with graininess of 0-7 mm. Sand pour 5-7 cm layer and flatter. The laying of the road material is proceeded from two extreme rows. Side stones are installed on a cement solution or a special border with a ledge.

There are gaps between the stones, at least 2-3 mm, which are filled with pure fine grained sand or dry mixture. Sand in the cracks tram, if necessary, be vacated and shed with water.

In the construction of tracks of any kind should be observed slope for water drainage. For this purpose, make a base with a convex shape so as to provide a bias 2-3 cm by 1 m from the track axis or a special drainage. For tracks with a slope greater than 5 cm per 1 m of steps required device. To determine the size of the rule stages: two stages plus depth of height equal to the step length of 60-70 cm Stepwise garden path made of plates measuring 40x40 cm at a distance of 60-70 cm between their centers..

Garden path tiles with their hands

Materials and tools

To lay the garden path with his own hands is necessary to prepare the tools and construction materials:

- sand,

- paving slabs,

- border,

- cement,

- cord,

- metal or wooden stakes,

- hammer,

- rubber mallet,

- shovel,

- long rule,

- two pipe sections 2.5 cm

- rammer,

- cart,

- building level,

- master OK,

- buckets,

- broom,

- bolgarka with a diamond disc,

- kneepads.

Marking the route of the future path

Route garden path is marked by metal or wooden stakes and tensioned therebetween cords. In places the track bends, pegs hammered tightly. The layout of winding paths make an ordinary garden hose.

By width of the designated track is removed soil to a depth of 25 cm. The removed turf used for lawn. The base of the track check building level.

laying curbs

First set curbstones. With long slats and long bias level is checked prepared track foundation. If the ground loose, curbstones put on a thin layer of concrete.

Preparation of the foundation

In the prepared trench fill a first layer of gravel or stone, brick chips. The layer thickness of 10 cm. It performs a drainage function. Bulk material is thoroughly tamped.

On top of gravel poured, dub and compacted gravel or coarse sand layer 10 cm. To the sand cushion is well sealed and not sprawling when walking, it is recommended to put a tile on her temporary wooden bridges.

Laying tiles

A bar of rectangular and square shaped stack, leaving gaps (seams) which are later filled with sand. Sutures provide drainage of rain water and melted snow. Profiled tiles more complex shape fits seamlessly and tightly fitted to it is "caught" as puzzles.

If the sand is tightly rammed, then the tile is simply fitted onto its surface. If loose, then the stones with light rotation are pressed into the sand. Stones are packed with a hammer through a wooden bar so that they lay in the same plane. The construction level is controlled by a bias.

Sand poured on the laid tile and remove in the seams, then the track is abundantly watered with water from the hose or watering can. In the case of poor-quality sealing of the seams, after the sedimentation of the sand and drying the water, the procedure is repeated.

Putting garden tracks homemade concrete slabs

The tracks from concrete slabs look good at any garden plot. They are distinguished by durability and practicality. The technology of arrangement of such tracks includes two stages: the manufacture of plates and their laying.

Necessary materials:

- wooden bar,

- steel sheet,

- cement,

- sand,

- gravel,

- previous dry mixture for concrete,

- armature - steel bars, steel mesh, polymer fiber,

- pigment,

- decorative elements (broken ceramic tiles, pebbles).

Form for homemade concrete slabs

The size and form of concrete slabs depends on the width of the garden path. There are special plastic forms for the manufacture of concrete slabs of various shapes and sizes. It is completely easy to make a form for plates from concrete with your own hands.

Most often, square plates with a side of 30 to 50 cm are used. For molding the plates, several wooden forms are harvested, the total volume of which is equal to the number of concrete per seam. For assembly forms use wooden bars with a cross section of 50x50 mm and a steel sheet.

Bruks are fasten with nails. So that the finished stove is not stuck in the form, the bars from the inside are grinding and stained with oil paint.

This form can withstand multiple fill. There is a simplified method: a form without bottom on a flat surface, covered with polyethylene. When concrete hardens, the form is slightly expanded and take out the finished stove.

Cooking concrete for homemade plates

To knead concrete, cement is required, clean sand and gravel in proportion 1: 2: 4. In construction stores for sale ready-made mixes. For small works, concrete is mixed manually. For large-scale construction, they buy or rent a concrete mixer.

When mixing concrete, the amount of water is required, equal to 20-40% of the weight of cement. Water is added gradually. The strength of concrete is reduced from excess water. A high-quality concrete is a wet plastic mass that keeps the form and does not crumble.

Decorating concrete slabs

To give color to concrete coating, pigment dyes are used, refilled in concrete when mixing. Natural, synthetic pigments and complex compounds from coloring additives of different colors are sold. More often than other mineral dyes are applied: protection of yellow and umbra brown.

Enjoy the other reception of decoration: plunge into the surface of concrete pebbles, fragments of ceramic tiles.

To do this, first on the bottom of the form lay a sheet of paper, it is attached with water-soluble glue decorative material and poured with a concrete mixture. With a frozen slab paper is easily flushed with water.

Reinforcement and fill with concrete solid

Concrete solution is filled with a third or half of height. Put the reinforcement. A steel bar is used as the reinforcement (cross section of 5-8 mm) in the form of a lattice, the finished reinforcement grid. The form is poured by concrete to the top. For reinforcing plates, polymer fiber is also used, it is added to the concrete when they are kneaded.

The concrete mixture in the form is aligned and withstand two to three days, regularly wasting the surface with water or cover with a wet cloth.

Laying concrete slabs

If a significant functional load is planned when using a track (truck with cargo, bike), then between the plates leave the minimum clearance 2-3 cm. The gap 5-6 cm looks aesthetically and hides the lack of laying. For pedestrian walkways, plates can be placed with a step interval.

Character by the track. Remove the top layer of soil by 10 cm. Trench on half depths fall asleep with sand. Concrete slabs are put on a smooth sandy base into one or more rows across the width of the track.

It is important that each plate with the entire plane relied on a sandy pillow and there was a floss with adjacent plates. For dense fit, the plates are closed with a hammer over the board.

The slots between the plates are filled with sand. Garden tracks are very decoratively, if putting lawn grass in broad gaps. To pave the track on the finished lawn, the hole is cut under each stove and remove the turf. The bottom of the holes fall asleep with sand so that the stove lay on the same level with herbal cover.

Garden tracks from girlfriend materials do it yourself

Garden track from progressive means will cost inexpensively and will give a lot of positive emotions. To cover the tracks in the course there are a wide variety of materials: Steppingstones, Spike ends of logs, pebbles, plastic caps, round stones.

The optimal width of the garden lane is 1-1.5 m, and the paths - half meter. It is necessary to make a slope of the track, so that water is not stood. The track near the beds and flower beds make a few centimeters above, then it will remain dry after watering plants.

With a competent combination of materials, the tracks from the primary means look very stylish.

Wooden garden track with their own hands

From the barrel of an old or dyeing tree, you can choose a garden path.

Materials and tools:

- log or trunk of an old tree

- petrol or electric saw

- polyethylene film in the form of a roll or red clay,

- brush,

- metal container,

- sand,

- concrete,

- olife

The trunk and thick branches are cut into rings with a thickness of 5 cm of different diameters. In a large metal tank, the olive is heated to a boil. With the help of the brush process the rings of hot olifa from all sides. Leave until complete drying.

Laying wooden spil tracks

First determine the size and route of the future track. For the pavement of the track from sleep and chumbage prepare a trench of 30 cm deep. The bottom of the trenches is covered with a polyethylene film or fall asleep clay. It is necessary for waterproofing and protecting the tree from rotting. We fall asleep in layers of 5 cm with coarse sand, trambed and watered with water. The height of 10 cm height is put on the sandy layer tightly to each other. Small gaps are inserted into the gaps between large checkers. The construction level check the arrangement of the rings in the same plane. The remaining slits are filled with sand or poured concrete. Walkways out of sleeps are usually made with a border.

Garden stone stone with their own hands

For the construction of garden tracks, quartz sandstone is most widely used, on another "savage", Lugansky stone or ocher stone. Sandstone has the form of a dense plate of ribbon shape of different sizes. It makes decorative tiles and a blocking.

Sandstone - durable, dense, frost-resistant stone. It practically does not absorb moisture.

Required tools and materials:

- cord,

- gravel,

- sand,

- shovel,

- master OK,

- building level,

- kiyanka or rubber hammer.

The cord is chopping the borders of the future track.

On the bayonet shovel dig up the land.

Fall asleep gravel. Sand pour over the gravel pillow over. Tightly laid a paving and customize with a hammer. The construction level is checked, even the surface of the track. Stone slabs or paving laid from one edge, to another. Sand poured on the laid and remove it in the gap.

Garden track made of pebbles do it yourself

Decorative pebbles - finishing material, which is always relevant. It is durable, practical, with spectacular appearance.

Of this simple and affordable material as pebbles, lay out the extraordinary beauty of the garden tracks. The coating can be completely pebble or combined with other materials. Almost all types of coatings for garden tracks are successfully complemented by packing elements from pebbles.

First on paper make up the path of the track and the pattern of the color designation. You can create a pattern model using a computer program. Conduct sorting stones in size, shape and color. Put a test sample from pebbles on the sand.

Drop the groove with a depth of 30 cm, align the bottom. Sand bully with a layer of 10 cm and compact. The next layer with a thickness of 20 cm made of fine granite rubble. The rammed crushed stone falls asleep with a sandy cement mixture in a 3: 1 ratio and align.

Place the pebbles according to the pattern of the pattern, taking into account the size of the stones and the distance between them. For marking use pegs with stretched twine. Pebbles lay on the edge or plafhmy, in the second case, the consumption of the stone will be smaller. Mixed pebbles are poured with a rubber hammer.

The surface of the track cover should be higher than the level of the surrounding land so that water does not accumulate. After laying pebbles, the track is watered with water from the hose with a sprayer, the water jet should not be strong. The cement-sandy mixture absorbs water and settles. While the mixture does not harden, it is impossible to walk along the track. Then the cement-sandy solution is mixed and the gaps between the stones fill them, so that the pebbles spoke from concrete to several millimeters.

Garden tracks from round stones

Boulders look very natural in any garden. They are used as a cover and instead of borders. Especially beautiful boulders with a motley sandstone structure, granite and porphyra.

Boulders are placed tightly to each other on a sandy pillow with a thickness of 15-20 cm and drive in the sand with a rubber tip. Stones are installed flat side up. It is necessary to observe the SCO path for water drain. After laying the stones, the slots between them are filled with sand. The finished path is watered with water and again plunge the sand in the intervals between the boulders.

Borders

Borders serve to strengthen and maintain the edges of the garden tracks, give them a complete appearance and prevent the growing grass. Border happens different heights and shapes. It should be combined with a coating track.

Plastic border

Plastic borders are comfortable, durable. They differ in simple installation, as they are attached with anchor pins, which provide solid fixation. Due to flexibility, plastic borders are indispensable for the design of winding paths. They are used to strengthen the contours of the gardens of any type. Borders of plastic are not noticeable, but are a reliable barrier from the growing of lawn grass and rolling the bulk coating.

Metal border

Metal curb - the perfect option for the fence of the paths covered with rubble. Metal borders are ribbons made of steel, copper and aluminum. They firmly hold the pathways, prevent the germination of weeds. The metal ribbon is plunged into the soil by 10-15 cm and performs above its surface not more than 2 cm.

Wooden border

Wooden borders are often used in the Gardens in the "Rustic Style". Usually they protect bulk tracks and wooden coating tracks.

As a border, a wooden timber treated with an antiseptic or small scuba is installed. There are ready-made sets of bubbach connected wires.

Brick border

The border of the brick is traditional and well combined with the paving from boulders and paving stones. He looks harmoniously in classical English garden and a summer cottage in a rustic style.

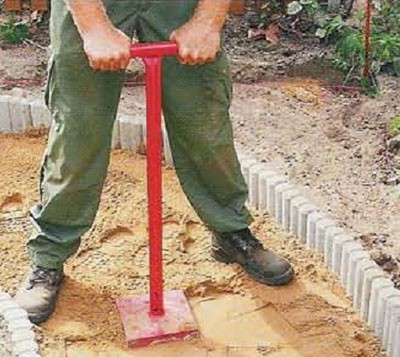

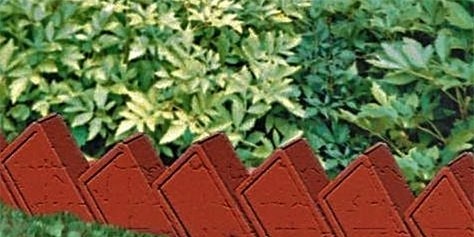

When installing a curb, bricks are bought into the ground along the edges of the garden path in the form of a teeth. Under the influence of harmful climatic factors, ordinary bricks are rapidly destroyed. For borders, it is preferable to use strong facing bricks.

Borders from natural rocks

Border stones made of marble, granite, limestone, shell and sandstone look very organically in landscape gardens with natural landscape. The border of the stone is well combined with a coating of granite, paving stones and paving slabs.

Before installing a stone border, the soil is covered with a mulching non-woven material (spunbond). Located small stones of the same size and shape, the gaps are filled with small stones and fill the gaps with dry cement.

"Green" border

Live border is universal for all garden styles. It looks beautifully a low live elevation with gravel, rubble, natural stone and tiled for sidewalks.

This is the most time-consuming type of track design. To create a green border, plants are planted in a row of 30 cm wide. Most often along the tracks are planting the brushes and the caticker horizontal.

The material of the border may differ from the coverage of the track, the main thing is that it is durable, stable and aesthetic.

successful tracks!

Even in the smallest garden without a tracks can not do. They help organize the space of the garden plot, facilitate the execution of dacha works, decorate the garden and make pleasant walks. The well-thought-out location of the tracks, the choice of a suitable coating, compliance with the rules of laying and a bit of creativity - these are the necessary conditions for the arrangement of a solid and beautiful garden track. It does not matter from which the track is made, from expensive modern materials or remedies. If you work with a soul and great desire, a successful result will be provided.