Manual pipe bender do it yourself: scheme, materials, manufacture Instruments

It is not always possible to pave pipes exclusively in a straight trajectory - the bends and turns of a different angle along the entire length of the highway are inevitable. All pipes come on sale primarily directly, therefore it becomes necessary to bend them for specific parameters on their own. Manually do it, especially if profile products or durable metal seems possible. That is why there is a special device - manual tube bender, to make which with their own hands quite under the power of almost any master. Find out how to collect such a tool with your own hands, in this article.

Content

Why do you need pipe bender?

To understand why it is still needed in the household of manual pipe bending and in what work it can be useful, we allocate only a few most popular options from all possible directions for the use of bent pipes - this is:

- installation of engineering systems - sewage, water supply, ventilation and air conditioning;

- installation of fences and grids on the site;

- design and assembly of garden furniture;

- creating greenhouses;

- installation of a canopy for a car.

Important! Depending on the desired volume of bent parts and complexity, choose the appropriate version of the pipe bend. It may be the simplest hand-made pipe bending, profile or hydraulic, whose use is advisable to change the type of steel pipes. The last option will also help to quickly cope with the task, if you need a large number of non-standard details.

What pipes can be bending?

There are no restrictions there, if the tool is correctly selected. You can get the desired form of details when using pipelines from:

- plastic;

- aluminum;

- become;

- metal plastic;

- copper.

Important! The choice of suitable fixture for flexible pipes has a great influence and cross-section of the pipeline itself, and its profile. For example, the usual round elements of the future system to give the right form is much easier than profile, without allowing their deformation or completely complete breakdown.

What is the usual manual pipe bender?

Equipment of a manual tube system will vary depending on the specific type of tool. But at the same time, any homemade handbreaker will necessarily have:

- frame - open or closed;

- top bar;

- lower bar;

- hydraulic cylinder - if it is hydraulic systems;

- 2 stops.

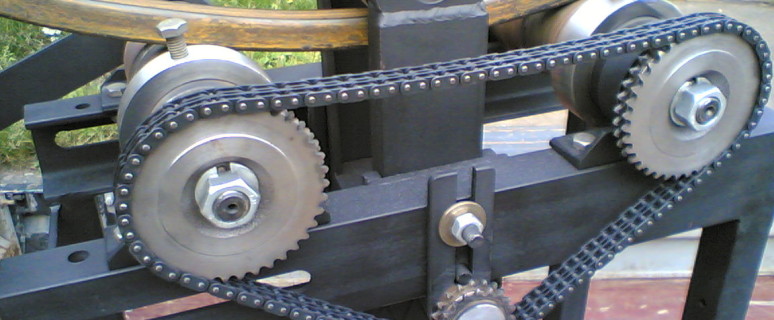

Important! In more complex devices, the scheme of manual pipe-bending implies the presence of a special power discharge device, which is mounted on the back of the case. In addition, bypass valves and handles can be added to ensure the most convenient and efficient use of the tool. If the hand-made pipe bending is made with their own hands from metal parts - gears, shafts to eliminate their rusting, violation of the integrity of the external contour, also establish a special compartment for supplying oil and lubrication. All items are often sealed with bolts, screws and nuts, but in some cases the locks and even welding will be required.

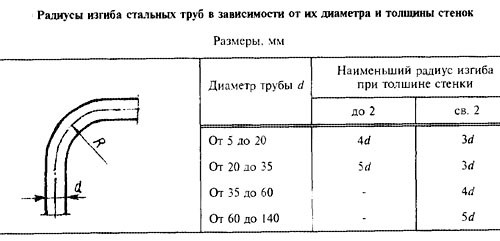

How to hit the pipe?

To eliminate the overrun of the material, the first thing you need to do is to familiarize yourself with the minimum allowable radius of the fester of the pipes that you plan to use. When calculating this indicator, the wall thickness is taken into account, the features of the material itself, as well as the diameter and profile. Find the data before entering the manufacture of manual pipe bending with your own hands. Below is the table of the minimum bend angle for frequently used metal pipes - read carefully with it.

Important! If you do not comply with these requirements, you will not be able to achieve a given quality of bending and pipe in the processing process can simply burst out.

How to make manual pipe bending?

Choose a suitable pipe-bend version from the following ways of self-assembly. Before starting work, make sure that all the necessary materials and tools are available, and also carefully consider the drawings of the hand-loading.

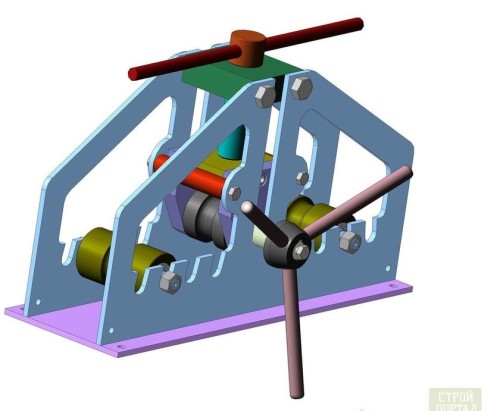

How to make manual pipe bending: Method 1

This method choose if the main requirement you have a high equipment performance. To make manual pipe bending in this way, follow the following recommendations:

- Take a suitable metal base.

- Secure it on a stable smooth surface.

- Over the ends drill holes.

- Take metal rectangular or trapezoid plates and drill holes in them to fasten the shafts.

- Fasten metal plates with screw and nut with screw and nut.

- Install the rollers of a suitable diameter in the resulting grooves.

- Securely lock them with spills and nuts.

- In the center of the base, attach several vertical profile square pipes using the welding method to form a rack for the third - deforming shaft.

- Secure it inside with a pylon and nut.

- To one of the shafts on the ends, attach a handle from a metal round tube.

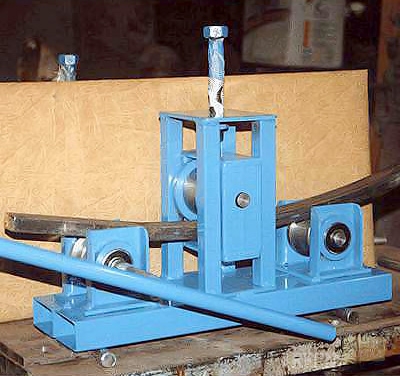

Important! As a result of the work performed, you will get a design as on the proposed photo. It is possible to simplify the design as follows - do not use additional material for the base of the case, and immediately screw the plates and the central racks to the base itself on which the instrument will stand.

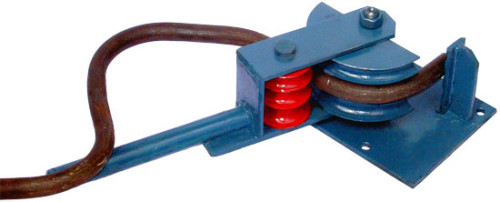

How to make manual tube: Method 2

The previous design version is quite complicated. It requires a pre-clear scheme and the correct selection of materials to obtain a really effective result. The following method is the simplest design option that will allow you to easily give the right shape with pipes with a cross section of up to 25 mm.

Perform work as follows:

- Create a hand-cutting drawing to determine the desired parameters of the template.

- Take any boards or other lumber that you have in stock after previous construction work.

- Drink them under the desired size, focusing on the parameters of the pre-created model in the drawing.

- If there are only small boards in the presence, make several parts for the subsequent connection.

- Build all the items in any way convenient for you - nails, screws, screws.

- Secure the resulting module to the table or any other base on which you will be flexible pipes.

- On the one hand, the template fasten the small bar, which will serve as stopping for the pipe when it changes its shape.

Important! When choosing a distance between these elements, focus on the thickness of your pipe so that you can insert it and fix it. To apply such a pipe bender, take the pipe, install it between the stop and the template model, take a bend carefully. Please note that it is necessary to change the product shape from the end, and not from the center. If you ignore this rule, you will not be able to withstand the parameters of the bend trajectory, and the pipe with this approach can burst.

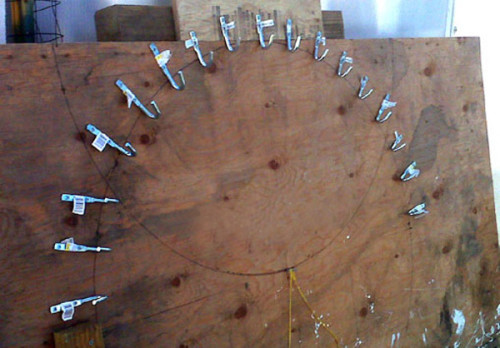

How to make manual tube: Method 3

Another option is a very simple design of a hand-made homepage, use which you can even to change the shape of the profile products of the rectangular and square cross section.

Progress:

- Take a big sheet of plywood.

- Secure it on a convenient wall for you.

- Take several metal hooks.

- Determine the arc you need.

- Draw a construction pencil line.

- Clearly fasten the hooks consistently using screws and nuts.

- As a lock, attach metal small plates to each hook - thanks to them, the pipe will not slip out of the tool when performing work.

Important! As the basis, you can immediately use a concrete wall, but then it will not always be possible to take advantage of the main advantage of such a pipe bender - the ability to change the bend radius for specific tasks. Note that such a tool you can use for flexible pipes of any strength and plasticity. For example, to get the desired result when working with metal products, it suffices to use a manual winch to increase the power supply. In this case, the work is performed very quickly.

Conclusion

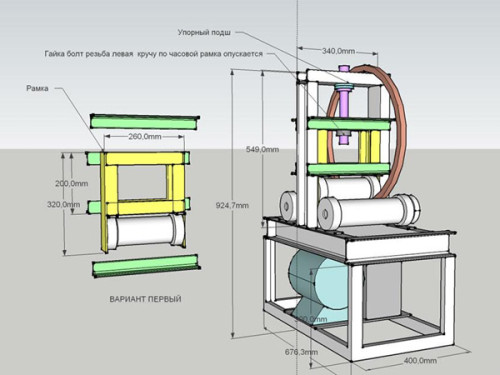

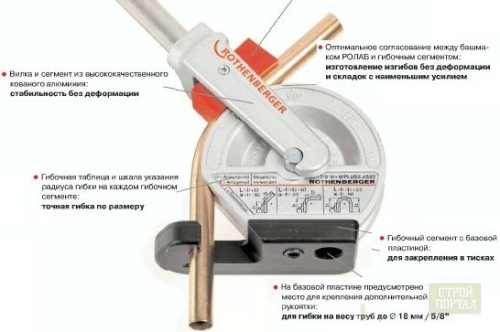

In addition to these ways, you can use other options for hand-cutting designs - their large enough. Here is another drawings of manual pipe bending from quite convenient options:

To clearly understand another design option, the principle of assembling such a tool and functioning, look at the proposed video review of self-made hand-cutting.

When choosing a suitable option to you, focus on the level of your professional construction skills, how often you intend to apply pipe bending, what volume of parts you need to prepare. Give the preference to the one with which you will be able to work as conveniently, and where additional expenses for the assembly will be required.