What to choose a tile grout Building materials

Upon completion of the selection of ceramic tiles on the wall or floor, the step of filling the seams by grouting. It is necessary to approach her choice with full responsibility, otherwise, over time, the surface will lose its tightness, and the selected color, instead of delighting the eye, will spoil the mood for life.

Content

What is grouting for tiles, its characteristics and types

The grout of the seams of ceramic tile is a homogeneous mixture based on cement or polymers having any color. It gives the tile coating a beautiful view, is a highlight, affects the overall tonality, but the main function of the grout is to become an obstacle to getting between the tiles of garbage, dust, moisture and home insects. In addition, in the blank intervals between the elements of the facing over time, a fungus or mold starts. This is especially true of wet premises. Mold mushrooms produce disputes into the atmosphere, which adversely affect human health, causing allergies and all sorts of diseases on its basis. In addition, if the mold once appeared, it would be very difficult to get rid of it, so it is better to ensure prevention in time.

Grout is classified as follows:

1. The mixture based on cement:

- with the use of Portland cement;

- with the use of portland cement and sand.

2. Resin-based mixture:

- using epoxy resin;

- using furana resin.

The grout on a cement basis is equipped with all sorts of additives that give it the necessary qualities, such as homogeneity, good distribution over the surface, easy filling of emptiness, non-burst drying. Such a mixture is used for seams with a width of up to 0.5 cm. It is usually produced in the form of a bulk substance, which is bred before use with water or liquid latex, bringing to a sour cream-like consistency.

If it is necessary to close the seams, in the width exceeding 0.5 cm, then the grout containing sand is used. Its homogeneity will depend on what sand used is fine-grained or coarse-grained. The color of such a mixture, as a rule, is gray or white, depending on the color of the components.

Cement grout is used for any tile, and grout containing sand is contraindicated for enamelled cladding. The fact is that even small grain grades can create noticeable scratches on such a surface and the appearance of the coating will be spoiled.

Epoxy tile grout In addition to the resin, in its composition coloring pigment, substances that give hardness and seam density. Due to this, they very effectively resist the effects of moisture and various kinds of chemistry.

The advantages of epoxy grout include the following features:

- not afraid of direct sunlight;

- elastic;

- not susceptible to fading;

- does not form stains.

The essential disadvantage is the complex application and the cost of grouting tile seams on epoxy resin. It is significantly higher compared to the price of ordinary mixtures.

There is a type of such grip - a modified epoxy mixture into which Portland cement is added. It looks like a conventional grout, but has greater efficiency, and in quality is close to epoxy grout.

Grouting on furan resin has a composition in which no water use is required. It is superal for any impacts, including aggressive acids. Along with impressive quality, Furanian grout has a serious drawback - it is extremely difficult to work with it. Before applying, the tile should be protected with wax, and at the end of the work of the surplus, remove the hot steam.

Furana mixes as well as epoxy is complemented by latex, portland cement and other additives. If we talk about the qualities, then this is the best grout for tiles, but for household purposes it is not used, it is used mainly for industrial and industrial premises.

Sealants and seals for seams

Some prefer to replace the grout with special sealants or seals. They used to be popular, because There were short-lived, swing tile and needed subsequent updating. It was uncomfortable and labor, so many masters preferred grout, although there was no special choice.

Today, science stepped far ahead. A new generation of sealants and seals appeared on the market. Now they have a rich color gamut suitable for any design room, without difficulty are washed off from tiles with simple water, easy to use and elastic. Seam filled with sealant look neat, rounded, have aesthetic appearance.

How to choose a tile grout color

The choice of color of the grout mixture is very important. The seams can add the tile color palette or give it another shade, adjust the minor shortcomings, emphasize the beauty. When choosing grouting, in addition to personal preferences, it should be guided by some rules that significantly facilitate this process:

- choosing a grout, do not forget that the color on a small sample in the store looks lighter than if you apply to a large plot;

- going to the store, it is better to take pieces of tiles with me to apply them to the samples of the grout;

- the classic is the case when the grout is selected either under the dark of the shades of the tile gamut, but not darker it either under the brightest;

- if the choice fell on the light grout, then the tiles will be slightly merged, if the dark is a brightly outlined geometric pattern;

- if the selected grout contrasts sharply with the tile, it is best to check in advance whether it will not paint the tile, and which color will get after drying;

- white grout is universal, so if you don't have to determine the color, it was not better to choose it;

- but the choice described in the previous paragraph is due to the margin in case of sex, in this case it is better to choose a mixture similar to the camp of the shade;

- if the grout is used in the bathroom or other rooms with high humidity, then it should be moisture-resistant;

- the original output is the selection of the grout color is not under the tile, but under the furniture, plumbing or other accessories;

- making the original course, do not forget that according to the generally accepted rule, the colors in the bathroom should not be more than three.

Grout of tile seams, its features

Such core mixtures differ from the rest of their homogeneity. The particles are very small and the total mass of something resembles flour.

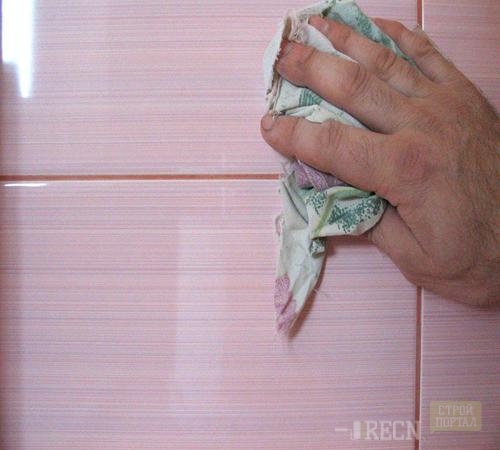

The powder is bred by water to a sour cream-like consistency, fill the cavities of the seams using a rubber spatula, after 10-15 minutes they are removed by a wet rag and leave for final drying.

Required tools and materials, such as a pelvis with a sponge and cloth, should be prepared in advance, so that during work everything should be done at hand. If the grout has already frozen, then remove it without scratching the surface of the tile, it will be extremely difficult. It is best to specifically highlight the day and work only with one grout to finish everything at a time.

When diluting the grout, the instruction should be strictly followed. It is important to pour powder into water, and not vice versa. Even if it seems that there is little water and a mixture of dryness, you must first stir everything thoroughly, and already, if necessary, dilute more.

The rubbing of the seams of floor tiles should have special qualities, for example:

- resistance to moisture action;

- durability and hardship;

- the impairment of mold and fungus;

- resistance to the action of chemicals.

Clinker

The clinker tile is manufactured by a special way from high-strength materials and has a certain structure. The use of liquid core mixture for it is not desirable, because The embossed surface will be clogged and dumping, and it is not so easy to wash it. In this case, the dry grout will be more proper. Works must be carried out in such a sequence:

1. To the grout beget better, take the sputter filled with water and splash the seams.

2. Prepare the mixture, bring it to the consistency of wet sand. Work with a semi-dry material, carefully score the seams. In advance, undress the film under the surface to be treated, so that it is easy to assemble the wakewicked surplus and again put into the case. Act in this way and then significantly reduce the flow rate for tiles.

3. Having finished horizontal seams, go to vertical. When filling the seams, do not block them. Then, when the work is finished, you will confuse everything tightly.

4. In the process of rubbing, all excess will leave, and the facing will take an aesthetic appearance.

5. Upon completion of the work, pass the seams on the seams in the diagonal direction. To make it faster, use the brush of medium or large size. At the same time, it should not be tough, otherwise the integrity of the lowest mixture will be broken.

6. Take the sputum again and spray ready-made seams, but do not twist them. So they harde it better and faster.

How to choose a grout for tiles?

Grout for tiles, which will not be difficult, because It is sold in any construction store, produced by different manufacturers. Which one is better, everyone decides himself. The most popular and demanded brands are Ceresit and Atlas.

Ceresit tile grout is made by the oldest German company Henkel Bautechik. Products manufactured under this brand earned love both professional builders and home masters, thanks to the highest quality and reliability.

Ceresit Mixed Mixtures serve for sealing tile seams, as well as glass and stone facing. They are used for floors and walls, when working inside and outside the room.

Grouting this company has the following advantages:

- moisture resistance;

- environmental friendliness;

- fast screwdriver;

- frost resistance and adverse atmospheric phenomena.

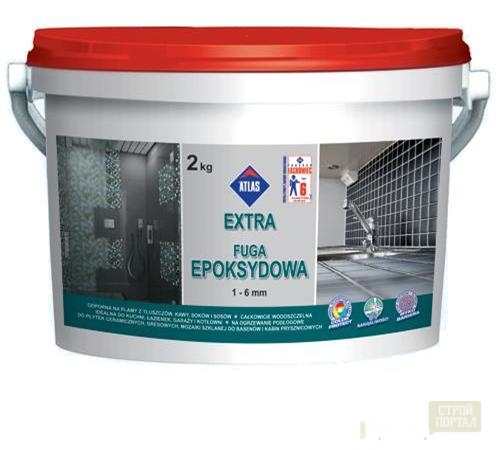

Also very popular is ATLAS. This is the Polish concern, which includes a whole group of companies. One of them is in Russia.

Grout for the tile "Atlas" serves to seal the seams of sexual and wall cladding from ceramic tiles, marble, concrete, mosaic covered with icing. It is used not only in dry and wet, but also in wet rooms, for exterior and internal works.

Advantages of the "Atlas" grout:

- plastic;

- simple preparation and use;

- the ability to fill the seams up to 0.6 cm;

- hardness, strength;

- lack of cracks after drying;

- resistance to mechanical effects;

- does not scratch the surface of the facing.

Buying a grout for tiles, the reviews about which is on the Internet, you should pay attention not only to them, but also on the shelf life and other information written on the package.