Filling floor concrete with her own hands Floors

The most durable, durable and qualitative basis for laying outdoor coverage can rightly be considered a concrete tie. With competent calculation and observance of the film filling technologies, concrete can be obtained a smooth solid surface under the desired slope. The decisive factor in favor of choosing this method for many is its low cost and simplicity of execution. In this article we will tell you everything you need to know about the Filling of Paul Concrete.

Content

Features of technology

Creating a concrete tie of the floor may be needed for various reasons, be it alignment, strengthening or restoration of an old basis. Working with cement and sand is quite dirty, so many prefer to entrust these professionals. However, the rates for the fill of the floor by concrete are often unreasonably overestimated, especially if you know the technology of performance of work - there is nothing complicated in it. A little diligence and hard work, and even an inexperienced person will be able to make a high-quality and durable floor at home.

There are several varieties of a concrete screed depending on the characteristics of the base on which it is performed. So, if you need to create a concrete floor on the ground, you can not immediately pour a solution, otherwise it collapses in the first year. In this case, pre-hydro and thermal insulation will be needed. The choice of materials for the arrangement of concrete floor depends on the operational features of the room in which the repair occurs - what load will be on the floor, which coverage will be on it, the level of humidity, etc. It affects the overall price of the fill of the floor with concrete or "wet" screed.

The device of a concrete screed can be classified according to the specifics of the preparatory work and the creation of the final layer:

- Knitted - this option is most often used in apartment buildings. Concrete floor is poured onto the slab overlap, increasing their strength, durability, aligning and insulating them.

- With waterproofing - such ties make indoors with high humidity. First, the hydrobarrier is placed on the base, and then the concrete solution is poured.

- With thermal insulation - concrete itself is cold material, but the insulated screed will make cut the heat loss from the apartment. This method is resorted mainly when concrete floor is made on a soil base, but you can organize such a floor and in the apartment.

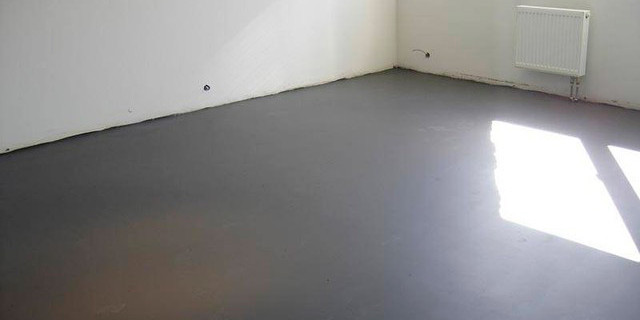

- The bulk is a screed, performed by special bulk mixtures, which, after frozen, form a perfectly smooth surface. Usually used in the preparation of gender to laying laminate, linoleum or other floor coatings sensitive to the slightest irregularities of the base. The bulk screed can be done only on top of the usual concrete. To do this, use special solutions with polymer additives or simply a liquid cement-sand mixture, which, under its own severity, spreads along the floor.

Thickness tie

The cost of filling the floor with concrete to greater extent depends on which thickness will be a screed, that is, how many materials will leave for the preparation of the solution. This indicator, in turn, depends on the characteristics of the base and the desired result (level of strength, thermal insulation).

In the case of apartment buildings, the restriction may be an excessive burden on inter-storey overlap. The total thickness of the concrete solution layer can be at least 25 mm and a maximum of 80 mm. If the screed is thinner than 25 mm, it quickly cracks, if the thicker is 80 mm, the load will be too large and the construction costs will be unreasonably large. That is why preliminary analysis and calculation of the number of materials are necessary. Thin ties up to 30 mm are designed mainly to equalize the base under the laying of the finishing coating. For concrete floor with a thickness of over 30 mm, experts recommend using solutions based on sainted river sand, different sided crushed stone and gravel - these fillers will allow formed a solid and durable coating.

Pouring concrete

Before filling the screed, you must prepare the base. If you are going to make the fill of the floor with a concrete with your own hands in the apartment, you should dismantle the old coating and clean the old concrete tie to remain "naked" inter-storey overlap. With the old coating, everything is clear, but why delete the screed? In some cases, it can be left if there are no visible damage on the surface. However, most often the old screed due to perennial loads loses its strength, covered by cracks and cannot serve as a qualitative basis for a new screed. In addition, it is an additional overlap load. As a rule, its thickness is about 5 cm. To dismantle you need a powerful perforator. The work is very noisy, so warning the neighbors about temporary inconvenience in advance.

In private homes, the situation is otherwise, since there the floor on the first floor is usually worth directly on Earth. In this regard, the cost of work on the fill of the floor concrete and labor costs will be higher.

How to prepare the basis for the device of concrete floor on the soil:

- Set the label with a simple pencil at an altitude of 1 m from the base of the doorway.

- Using the water level, transfer this label to the rest of the walls throughout the perimeter of the room.

- Return from the tags down 1 m - the lower marks will indicate the zero level, and you will see how much the floor should be aligned and to what level is to fill a concrete solution.

- Drink fine carnations in zero tags and tension between them a contrasting lace wall to clearly see the level of fill.

- Remove about 25 cm of soil, align the surface horizontally and thoroughly confuse. If there are no special equipment for tamping (vibrating plates), take the usual log with a wide board, brought to its end.

- Make a gravel suction with a thickness of 5 cm, pour it with water from the hose and confuse again.

- On gravel, pour 10 cm of river sand, plenty of water and sink. If under the floor it is planned to pave any communication, install them in insulating boxes simultaneously with a sweating of the sandy layer.

- Make a 10 cm layer over the sand over the sand, squeeze the surface and spray with sand so as to get a relatively smooth coating. The rubbank is better to take a varinfraction with the maximum particle size of 50 mm. These powders will perform the drainage function and take excess moisture from the back of the concrete floor.

Important moment: After creating each layer, check the horizontal of the floor with a building level.

Isolation device

If you make concrete floor to the soil or indoors with high humidity, the waterproofing laying is required. If you neglect this moment, the room will be constantly raw, and the porous structure of the concrete quickly has a moisture and collapsed. The easiest waterproofer for such cases is a constructional polyethylene film with a thickness of 200 microns. You can also use conventional rubberoid or modern waterproofing membranes.

To achieve the maximum quality of the pouring, lay the film at least 2 layers so that the cuts go to the neck for 15-20 cm on each other and on the walls. Between themselves fasten them with a sticky ribbon. If you work with rubberoid, glue it to bitumen mastic. Powders on the walls should reach the zero level. For the insulation of a concrete screed, basalt cotton wool, ceramzite, perlite, polystyrene foam and polyurethane foam, in general, any similar materials that can withstand load and relative humidity are used.

Strengthening tie

To protect the heat insulating layer and strengthen the screed, it is necessary to carry out reinforcement. From this point also depends on how much the fill of the floor concrete. Armature is needed for a thick layer under which insulating materials are located. For thin leveling screeds, reinforcement is optional.

To strengthen the floor, a metal or plastic mesh is used. It should be durable and moisture-proof, designed specifically for working with concrete. The metal network can be weave with your own galvanized wire 3-5 mm. If reinforced reinforcement is needed, you can take 8-15 mm metal rods, welded into the network.

Important moment: the network is placed on special supports so that after filling the solution it is inside the floor, and not with the edge. Stands can be made of metal pins, scoring them into the base so that the top ends are located in the same plane.

If you have to fill the concrete floor in a large room, install the formwork, conventionally dividing the floor area into several rectangular segments. The dimensions of one segment should be such that it can be filled with a solution to one, maximum 2 navigation. So in parts you can cover the entire area of \u200b\u200bthe floor, without fear of distortions and irregularities. For the construction of the formwork, you can use old boards or phanel.

Useful advice: so that the formwork is easy to remove, treat its elements with machine oil.

But the main auxiliary elements are guides - long metal rails, the upper face of which should be in one horizontal with a zero level. Guides are attached to the base with anchors or with a cement solution. They form the longitudinal sides of the segments, and the transverse are formwork boards.

Before mixing the solution, make sure that all guides and formwork are removed into a single plane with zero marks.

Pouring concrete

The secret of creating a durable and durable concrete floor is a fill in one occasion. A newcomer to cope with such work is very difficult, so it is better to divide the floor into several segments. If the means allow, it is better to order the composition of concrete for filling the floor at the factory so that it is delivered in the desired volume. But often the solution has to be prepared independently.

For cooking you will need a large plastic container in which you will mix the components, sinking river sand, cement and rubbing. For mixing, it is better to use a building mixer - a special nozzle on a drill. A brand of concrete for filling the floor should be no less than M400 (better than M500), since the strength of the coating directly depends on this. The sand you need to take exactly a sidewall so that there are no clay impurities left.

The proportions of concrete for filling the floor are: on the 1st of the cement there are 2 parts of the sand and 4 pieces of rubbank. At first, mix all the bulk components and only then gradually begin to add water, stirring all the mixer. Waters will leave about 0.5 parts. When the mixture becomes homogeneous and without lumps, immediately fill it into the formwork segment, located at the wall opposite to the entrance. You must move to the exit gradually, not to close yourself in the "trap".

Further actions are simple, but will require accuracy and efficiency:

- Once you poured a solution into a segment, take a building rule or a long straight board and stretch the concrete throughout the segment area.

- To remove air bubbles from the solution, process it with vibroma. If so is not, do you stick it with a wooden stick in several places. But in order to achieve maximum quality, it is better to rent vibrating plants in advance - the vibration-generated vibration quickly seal the structure of the solution and the air is guaranteed from it.

- After processing and leveling on the surface, the so-called concrete milk - muddy whitewash water should appear. As soon as this happens, you can move to the fill of the next segment. It is easier and faster to work together - when you treat a solution in one segment, the partner knead the next game and pours it.

- When you fill all segments in one row between the guides, align the surface with the construction rule. To do this, install it on the guides and stretch from one edge to another to smooth the surface and remove the excess solution.

- After that, it is possible to remove the shields of the formwork (crossbars between the guides), which remained on their empty place to fill with a solution, carefully align it and move it to the following segments.

- When the entire floor is flooded, leave the concrete alone for 3-4 days. Sprinkle it daily with water so that the evaporation of moisture does not happen too fast. Otherwise, concrete cracks. If the air temperature is too high (you work in the summer), wet the floor twice a day.

- After the specified time, the top of the solution should be captured. Cover the floor with construction polyethylene and leave it for 3-4 weeks until it is frozen. Polyethylene will prevent excessive evaporation of moisture and garbage.

- When the solution freezes, you can make a liquid cement solution or self-leveling liquid mixture on a polymer basis. For this, the solution is simply pouring to the floor, moving from the corner opposite the door to the exit. Such a screed dries 3-4 days, and at this time it also needs to be sprayed with water.

Below on video - Filling the floor with concrete in the apartment: