Fill and insulate the concrete floor in the bath independently Baths, saunas and pools

Previously, during the construction of a bath, it was customary to use solely natural wood. But the current requirements for bathing facilities have changed somewhat, have been changed by the canons of bunny architecture: the design of buildings has undergone a change, unconventional materials began to be used. The use of reliable and durable building materials, for example concrete, is fully explained by the modern pragmatic approach to solving construction issues.

Content

- Concrete floor in the bath - the solution is quite reasonable and rational

- Concrete floors in the bath - with what problems will have to face with their construction

- Preparatory work

- How to make concrete floor to a bath with your own hands

- Concrete warm floor in the bath - how to find out the number of materials

- Concrete floor device in the bath - We test the result of the work

- Finishing work

Concrete floor in the bath - the solution is quite reasonable and rational

Builders consider the construction of concrete floor in a bathhouse by solving cost-effective and correct. As the main argument they call a long service life of concrete. A qualitatively made concrete screed can be operated for over 30 years.

In addition, the concrete floor:

- dampness is not terrible and relatively high temperatures,

- he is not inclined to rot,

- its surface is not a favorable environment for the development of fungi and malicious microorganisms.

Caring for concrete floor is extremely simple, to maintain perfect cleanliness, it will not require the purchase of expensive means of household chemicals. The surface of such a floor allows you to decorate it with a tiled tile, which gives a bath room with a cozy and elegant look.

Concrete floors in the bath - with what problems will have to face with their construction

It is difficult to argue with the fact that a good result can be obtained without putting no effort to work. Concrete floor construction will require some knowledge and skills. Secondly, to fulfill the work it will be necessary to lease the concrete mixer, also when laying concrete there is a need for a portable vibrator, a high-quality construction level, a rule, etc.

But, having understood with the technology of the concrete floor device Bani, spending once the means and time, the pair owner acquires the opportunity for many years to get rid of the problems with repairs, and more specifically it gets savings and time for several decades.

Preparatory work

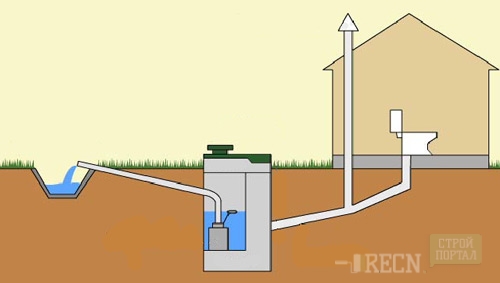

Bath - a special structure, it can be called the main consumer of water, therefore, the place where a large amount of effluent is formed. Before start concreting, the floor will have to carefully design the drainage system.

When drawing up a plan, a bath will be required to determine the point that allows you to easily equip the wastewater system. In such a place, the intermediate tank for wastewater. It is a hole, the minimum dimensions of which - 40x40x30 cm. The bottom and walls of the pits concrete, the thickness of the concrete layer - at least 5 cm.

From this tank make, with a fan tube with a diameter of 200 mm, drainage into a wastewall or septic tank. The end of the pipe entering the steam room or shower tools with a water shutter or a special valve - it will prevent the penetration of unpleasant odors from the waste system.

How to make concrete floor to a bath with your own hands

All work on the device of concrete floor can be performed with their own hands, but it will be necessary to strictly observe their sequence.

How to prepare the basis for the floor

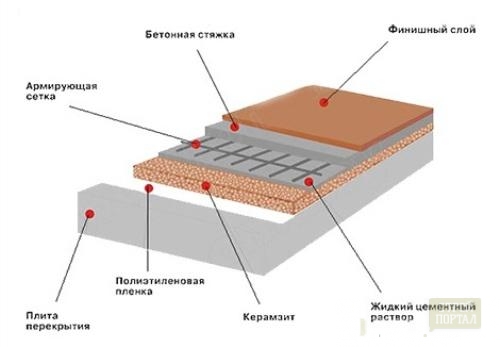

The base ground is thoroughly aligned, it is rambling. Next, the layer of gravel a large fraction is falling asleep, as a last resort - a brick battle, a thickness of 0.15 m. The next layer is 0.1 m rubble.

After the rubble trim, a five-meantimeter layer of concrete is poured. It should be taken into account that it is precisely this, the first concrete layer, should be given the desired angle of slope toward the reservoir for wastewater.

How to insulate concrete floor in the bath

Since a significant honor of heat loss in the bath occurs through a concrete floor, then after complete hardening of the first concrete layer, it will be necessary to carry out insulation of the floor in the bath. For this, it will be enough to fall asleep the entire slain area of \u200b\u200bthe ceramzite layer with a thickness of 0.05 to 0.08 m.

Heat the concrete floor in the bath can also be using mineral wool or construction felt. In the case of using cotton materials, an additional waterproofing of the insulation will be required. It can be performed using the rubberoid. The wall connection of the wall and concrete floor is recommended to pour bitumen.

How to prepare a solution with perlit

The device of the concrete floor in a mixer with insulation can be performed by cement solution with the addition of perlite. The material represents the mountain stream of volcanic origin and is distinguished by high thermal insulation properties. Since perlite is a volatile material, then work with it is carried out in a closed room. Perfect with a perlit is best in the concrete mixer, strictly observing the instructions indicated on the product packaging - perlite is significantly different from other materials in high ability to water absorption.

Features of the screed

The second layer of concrete is laid on the ceramzite or covered with waterproofing. Be sure to use the reinforcing grid, the wire or masonry grid can be used as a reinforcing structure. To give concrete, it should be tamped, align the surface with the help of a rule, apply a tightening solution from above.

For the pouring, their own prepared sandy-cement mortar is used. If tile will be used as a finish, it is better to purchase a special cement mixture, which is implemented in the ready-made stores in building materials. You can also use cement mortar with the addition of gypsum and anhydrate, i.e. self-leveling tie

Work should be performed quickly, so it is advisable to get sensitive assistants who can prepare a solution. The pouring starts from a long angle, the solution is reclocked by the cells, tighten the circular motions directed towards exiting the room.

To harden the screed, you will need a couple of days. To simplify the process of laying concrete and speed up the hardening, plasticizers can be added to the composition of concrete. Their presence contributes to a more reliable connection of the components components components, enhances concrete strength and prevents the appearance of cracks.

Although after a couple of days the screed will seem to be frozen, it is not recommended to expose it to significant loads. For a week it should be watering with water, it will be ready only three weeks later.

Concrete warm floor in the bath - how to find out the number of materials

In the design stage, it is possible to calculate an approximate number of materials that will be needed to work, and therefore - learn the approximate amount of cash costs. Experts argue that on average, a bag of cement will be needed on an average of a square of the square in a square meter. Based on the amount of cement, it is not difficult to calculate the amount of sand and plasticizer.

To calculate the number of insulation material, it will be necessary to know the surface area of \u200b\u200bthe floor and the recommended thickness of the insulation layer.

Concrete floor device in the bath - We test the result of the work

To determine how much the high-quality surface it turned out, you can perform simple testing after its complete drying. The homogeneity of the obtained layer of concrete will tell a mononographic gray shade of the surface of the finished coating. On high-quality and durable concrete after hitting the hammer should not be notable traces.

Finishing work

Ceramic tiles are usually used as a finishing material for the floor in the bath. The floors laid out beautifully look like, but it should be remembered that such a coating requires extreme caution - it becomes slippery when moisturizing. More practical option - Metlah tiles.

It is not recommended to use synthetic coatings and linoleum in shower rooms - when heated, they exude harmful substances that can cause severe intoxication in people.