Electric heating floor Floors

In recent years, electric warm floor receives increasing popularity. There are several reasons for this. One of them is the simplicity of its installation and maintenance. In addition, this floor can last long enough. In some countries where a predominantly cold climate, such a type of heating today is simply indispensable. In addition, there is a combined version of the heating of the room. For example, a combination of water heating and a warm floor. This option may seriously reduce the cost of electricity in the cold period.

Content

In general, the warm floor appeared not so recently. He actually has a rather ancient story. For example, similar to the principle of heating was used in the baths in ancient Rome. Smoke on special channels passed from the furnace under the floor and heated the room in this way. Well maintained heat at the same time stones. Despite the appearance of water heating, which became more accessible to most people, heated with the help of the floor did not forget, even continued to use. In the past few decades, one of the most popular ways of heating the room was a warm floor electric, the price of which depends directly from the manufacturer. To facilitate the task, tell you how much the warm floors are electric, focusing on prices in large Russian cities. Thus, the cost of electric heating floor (one square meter) varies from 80 to 140 dollars.

Differences of warm floors from ordinary heating

What is the difference between the warm floor system from ordinary water heating? To understand this, you need to remember how normal heating works. Under the window on one of the walls, a radiator is installed. The placement in this place is not chosen by chance. The fact is that through the windows is lost the most heat. Warm air has a property to climb up, while the displacement is colder, and in turn heats up when it passes directly through the radiator. Obviously, as such as heating, the room is not even uniform. The radiator is too hot, and far from it is cold. The most optimal temperature will be approximately one and a half or two meters from the radiator. As for the warm floor, it works completely differently. First of all, it warms a much larger surface than the radiator, because it is usually stacked throughout the room area.

No need to forget, the optimal temperature for the feeling of comfort by the owners of the room is 25-28 degrees. In the case of a warm floor, the comfort zone of the required temperature is located at a certain height over the entire area of \u200b\u200bthe room. This is usually about one meter from the floor. At the same time, colder air is in the top of the room. But it does not cause discomfort in a person, which is connected directly with his physiology. This all applies to the advantages that electric warm floors have. Reviews of premises owners where such heating systems are installed, it is clearly confirmed.

Due to the peculiarities of the heat-insulated floor of the electric, indoors with this method of heating it is fairly easy to adjust the temperature. To do this, turn the temperature control knob. True, this applies only to electric floors. If water or combined warm floors are used, the temperature will be regulated problematic. In addition, it should be aware that the effectiveness of the operation of the warm floor depends on how the carpet cover is indoors and is there any large-sized furniture. After all, any material has a certain level of thermal conductivity. This indicator is important for the selection of thermal insulation and material covering the floor. Next, we will tell you about how to make an electric warm floor.

Electric heating floor laying options

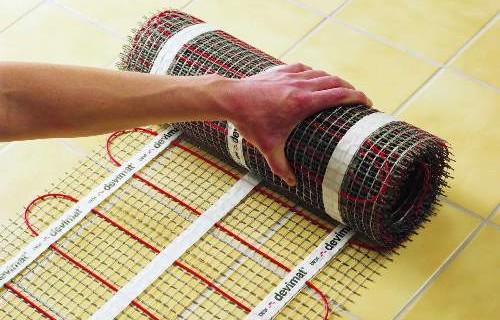

There are several ways to equip a warm floor electric. Video posted in this article, it clearly demonstrates.

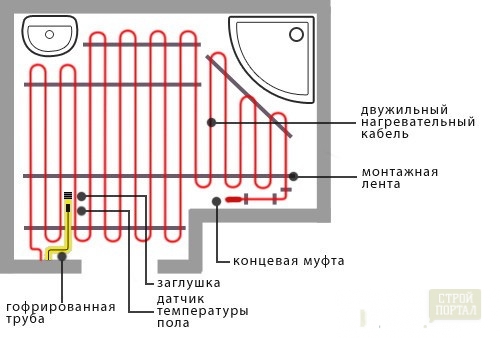

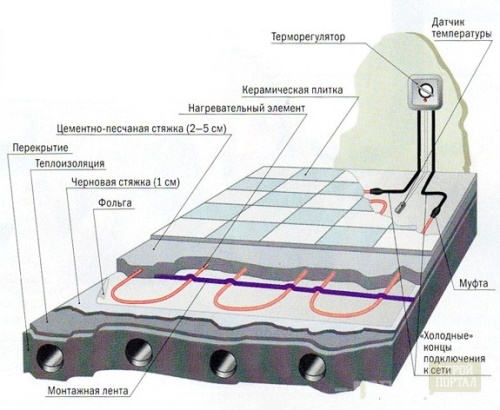

- When installing this type of heating, for heating of such premises as a kitchen, a room, a bathroom and a loggia, you can use the option to mounted in a layer of screed. After that, the flooring is lined up. When using this method, cable warm floors are most often choosing. Under the system of warm floors is placed a layer of waterproofing and insulation. Then there is a small layer of screeds.

- If there is a room already on the floor below, already having insulation, you can use another option for arranging a warm floor system - over the tile on the tile. In this case, the layer, both the tile itself and the tile glue, have a good protection of the heating elements. Nevertheless, it is better to see in the instructions attached to the product whether such an option is possible.

- Another installation method can be called special film floors, which are stacked under the floor covering. This option is suitable in the case when the electric heating floor laying is required for laminate or linoleum, but it does not want to make capital work on replacing the screeds. In this embodiment, over the already existing screed, the insulation is usually placed in the form of foam polyethylene with a foil surface. Also important item is electrical elements. If there is a need to add a layer of waterproofing, as well as the floor covering itself.

Instruments

For work, first of all, you need to purchase a system of warm floors.

In addition, you may need: connecting wires, mounting, knob, protective shutdown device, copper cable as a grounding agent, as well as a thermal sensor.

Planning and distribution of heating elements

- At the beginning of work, you must definitely plan the surface. Distributing direction nodes and heating elements, first of all, you need to create a mounting plan on paper. With it, it is necessary to ensure that the film and heating wire should not be laid in places where there is large-sized furniture and household appliances. In addition, it is necessary to provide enough free space in which heating elements will not be installed. Such zones include places where heat sources are undergoing, including heating pipes. The fact is that heating elements that have similar contours are heated equally. If the outside receives heat or there is a limit on heat outlet (for example, furniture interferes), then because of this, elements can simply overdo it and thereby fail. In addition to the heating elements, the furniture itself may be damaged.

- Ultimately, the plan should be an irregular figure that fits into a rectangle. This rectangle schematically depicts the walls of the room. According to contours and the inside of the resulting figure, a warm electric floor will be installed. Looking at the scheme, you can understand the main disadvantage of this heating system. It lies in the fact that when the furniture is permitted, the system performance can deteriorate greatly.

- In general, for different premises on the plan you need to draw your contours. Moreover, even if the symbolic border will be present between them. Each contour will have their own regulators and their nutrition. If you make the fill of the screed, then between them, on the floor, you need to lay a damper tape.

- When you all were well planned on paper, you can transfer this markup to the floor. Where it is convenient to mark the location of the regulator. In the selected place, it is necessary to make a hole for the installation of the mounting box, and it is also necessary to lower the floor strobe.

- After all major preparatory work and the preparation of the plan, you can calculate the desired number of materials. In order to do this, it is recommended to use the tables provided by the manufacturer of electrical floor systems. Selection of the necessary step laying of a warm floor should be selected according to the calculation of heat loss.

When carrying out the calculations, it is necessary to take into account the wire for connecting the regulator and the heat floor from the meter. In addition, the calculations should take into account the wire from the regulator to the elements of the heating system. After that, you need to check the general entry into the ability of the system to withstand the necessary load.

Surface insulation

If required, the old layer of the screed is necessary without the residue to dismantle to the base. At the same time, the entire working surface is thoroughly cleaned. After that, layer of waterproofing should be laid, which should be approximately 10 centimeters.

Next, to compensate for thermal expansion, when heated, it is necessary to secure the damper tape on the wall. It should be done throughout the perimeter.

So that the heat does not go down, you need to isolate the base of the floor. Suitable insulation should be selected depending on the type of surface, the main objective of the installation of the system and the location of the room. So, if the installation of warm electric floors is performed in order to supplement the main heating system, then a layer of foam polyethylene coated with foil is best suitable as a substrate. If the warm floor needs to be installed in the loggia or a veranda, which was not heated before, then a rather thick layer of the insulation should be made, which consists of a layer of mineral wool. On top of the insulation, it is desirable to put a reinforcing mesh, but it is enough to add to the existing microfiber solution and plasticizer.

Installation of electric heating floor

Consider how to perform installation of electric heating floor. The price of such a type of work can be reduced if the flooring is performed independently.

- Before performing the styling of the wire, check its resistance. It should be as indicated in the passport with the presence of deviations by 10%. Installation of the floor is allowed to perform in two ways: with the help of special fastening tapes or fastening to the reinforcing grid. If the floor needs to be equipped in the bathroom or bath, then this grid should be grounded using a tinted copper wire.

- Infrared warm floor When installing, it is necessary to put on top of the insulation. At the same time it may be needed with the help of special ears. Sometimes it is required to use construction scotch.

- If necessary, pave the warm film floor in places where two plates are connected, then to minimize the risk of wire break, it should be hide in a segment of the corrugation. The place where the heating cable and the wire are connected must be at a distance of about 10-15 centimeters from the shoes. In this case, clips can then be dried into the screed.

- When the items are in their places, you should check the cable resistance indicator again. You need to test the floor only if it is deviated in the permissible values \u200b\u200bfrom the norm. The operation of a warm floor is usually adjusted with a thermal sensor, which is placed inward corrugated pipe. If all stages of laying are made correctly, the entire system should be deranged, and the regulator is removed until the remaining finishing works are made. When the screed is formed and dried, you need to check the operation of the system again. If there is no need for tie, then the linoleum is immediately fit or laminate.

What is wrong when installing the floor

- One of the frequent errors is that when choosing a cable or a mat for a warm floor, the total area of \u200b\u200bthe room is taken into account. In fact, it is more correct to consider only an area that is not engaged in furniture. The fact is that under constant items (for example, furniture), which occupy a large area of \u200b\u200bthe room, the warm floor does not make sense to install. Moreover, otherwise it is fraught with overheating and a breakdown of heating cable.

- Sometimes mistaken when choosing a cable length. It must be remembered that the length of the cable you chose is no longer possible to reduce. This is due to the fact that shielded two-housing heating cables used in such heating systems should not cut under any circumstances. Otherwise, his breakdown may occur.

- Sometimes mistaken with the moment of switching on the cable to check its performance. For the first time, it should be done only when it is already laid, and the screed and glue are dry. If the cable is turned on earlier, even for a short time, it may deduce it. If you need to check the cable, but it does not include it, then it is enough to measure its resistance.

- Often the warming cable is placed on a contaminated surface. Do not do it. It is best to clean the floor with a vacuum cleaner, and it is also well to treat it with a primer.

- In addition, it is not recommended to walk through the heating cable or mat in solid shoes. This is allowed to do only in extreme cases.

- You also need to be attentive to the temperature sensor. It does not need to be tinted in solution. It is more correct to first place the sensor in the corrugated tube. It should not be present holes through which the solution could get. It is necessary so that the sensor can be easily removed and replaced if it breaks.

- Do not forget to measure the resistance of the warm floor at all stages of work - both before and after installation. It must correspond to the value indicated in the passport.

- In addition, it is not necessary to underestimate the drawn circuit of the warm-alone arrangement. It helps to navigate when installing.

- Do not leave unnecessary spaces around the warming part of the cable. This is especially important if a thin warm floor is installed. After all, otherwise, it can lead to a banal overheating of the cable or failure.

- Sometimes the connection of electric heating floor is carried out immediately after installation. This is not worth doing, because you must first wait until the screeds are completely drying. If you turn on the floor before, you can damage it.