Brick facing of walls Useful advice,Walls,Construction

Walls of brick and wooden houses are very often lining outside the extra brick layer. This is done in order to enhance thermal insulation and give the structure a aesthetic appearance. As a heater, glass and mineral wool are used, placing it between the wall at home and facing.

Content

Three-layer walls with brick facing: their purpose, device and disadvantages

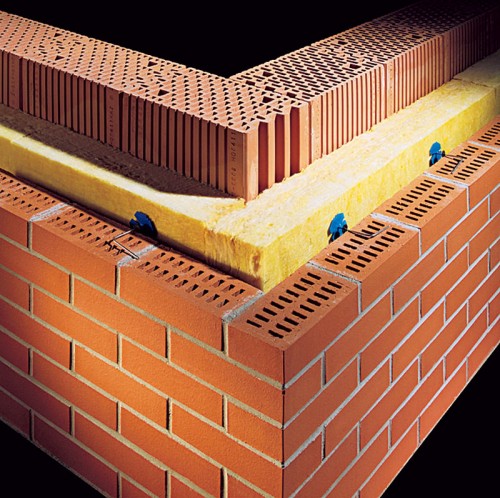

Such walls are equipped in low-rise buildings. Each of the layers consists of various materials:

- wooden, brick or other carrying wall, which is a power frame building;

- the layer of insulation and noise insulating materials fixed on the wall;

- a layer of facing brick, which serves as protecting the insulation from adverse external influences, and also makes the house neat and beautiful.

The mines of three-layer walls include the following features:

- the lifetime of the facing is much larger than the service life of the insulation;

- some insulation can allocate a substance dangerous to human health;

- it is necessary to take care that the wall does not send and not blocked;

- Polymer insulation are susceptible to burning.

Preparation of a wooden house to decoration brick

Preparatory work consists of the following steps:

- Strengthening the foundation. The fact is that in wooden houses the walls do not create a large load on the foundation, and therefore it is usually done rather weak. But if you build a building with brick, then the severity will increase at times, so this preparation stage is mandatory.

- Check the beam beams of overlaps. This action is important to produce immediately before the start of the facing. This is especially true for old houses, the elements of the design of which could be spoiled by time, mold, dampness, fungi. In addition, you should check the availability and quality of the ventilation system in the basement and space between the beams.

- Strengthening or complete beam replacement. This measure is made according to the results of the above check, if it is found that these parts of the design are outdated and lost strength.

- Processing walls and all wooden elements by antiseptic means, which will prevent the development of rotting processes, the appearance of mold and fungi. It will also not be superfluous to use funds that reduce the exposure to the burning tree to a minimum.

The advantage of a wooden house is that its manufacturer's material perfectly holds heat, so it is not necessary to lay the insulation between the wall and the facing at all. Of course, with such a layer will be more reliable, but if time or means are limited, it is quite possible to do without it.

As a material for outdoor cladding of a wooden house, a clay or silicate brick burned in a special oven is most often used. The solution for fastening elements of masonry between themselves is made of lime, sand and cement. A wall that will be facing brick must be smooth, and the masonry should be placed in a strictly horizontal position.

Brick lining of a wooden house

To fix the brick masonry was reliable, in addition to using the solution, metal galvanized pins are driven into wooden walls. The distance between them horizontally should be equal to one meter. In the vertical direction they are located in the place where the fourth row of bricks.

No matter whether thermal insulation will be laid or not, there are 50 mm gap between the wall and facing. Even if it remains empty, his role will be to ensure that the moisture does not accumulate under brick masonry. It is also impossible to forget about the ventilation holes. They must be left in brickwork every 3 meters. To avoid falling into the cavity of insects, the holes are closed with a shallow metal grid.

The calculation of the required amount of material is quite simple. One-square meter of wall masonry is approximately 50 bricks and 10 fastening pins. For ribs, approximately 30 bricks and 15 pins are required.

The work process looks like this:

1. Remove all elements protruding the surface of the wall, such as platbands, bias, etc.

2. Take the boards with a cross section of 10x2.5 cm and set the framework in which the insulation will be laid. Mount them with an interval of 550-580 mm. Such a distance is equal to the width of almost all sheets of insulation. Frame Fix with self-drawers - this is the most convenient way.

3. Lay down the insulation. Its thickness should be equal to the width of the boards used for the frame equipment. In this case, it is 10 cm.

4. When the insulation is laid, cover it with a special vapor-permeable membrane having water-repellent and windproof properties. Lock it on the frames of the frame of the furniture stapler. This film is arranged in such a way that the pairs go out of the house, but cannot penetrate in the opposite direction. It is necessary to lay it as a certain side inside, which one, usually indicate the instructions. Fix the membrane from the bottom up, making at the junctions of the nest 100 mm.

5. Now proceed directly to the execution of brickwork. Facing, as mentioned above, should have air vents. For their arrangement at the bottom of the walls do not fill the vertical gaps between bricks with mortar.

6. The brick layer must be associated with the walls of the house, for example, using a grid with 5x5 cm cells. Fix it with screws on a wooden insulation frame.

Errors, often allowed when cladding wooden walls brick

1. Some do not consider it necessary to leave the gap between the wall and cladding. This is a gross violation. The fact is that in winter, warm pairs pass through the walls and face icy bricks. In this regard, condensate is formed on the wooden wall and the surface of the facing, from which the walls are swung and rotate, and on the front surface of the brick appear astes.

2. Sometimes, by ignorance, the walls of a wooden house for imaginary protection are protected by a pergamine or rubberoid. But this opinion is mistaken and can lead to unpleasant consequences. These materials do not miss the pairs, so moisture will appear between them and the wooden wall, as in the previous example, moisture will appear. True, the brick will remain dry, but the walls will inevitably begin to rot in any time.

3. Also an error is the use of playproof insulation. They also contribute to the formation of moisture and reduce the breathable ability of the walls to a minimum.

Facing brick walls

In the case of facing of brick walls, all insulation that were unacceptable for the previous version are suitable. These are materials with low or zero air permeability, such as foam, foamed polyethylene, EPPS.

In this case, the dew point will be:

- In the insulation. Thanks to weak vapor permeability, moisture if it will appear, then in a very small amount that cannot cause any damage.

- Behind the insulation. In this case, a small amount of moisture will be collected in the thickness of the brick wall. For a brick, it is not scary, with this if the atmosphere in the house will be too dry, then the moisture from the walls will be transmitted to the room, creating a comfortable climate.

The brick facing of the house, the photo of which is presented below, is attached by means of a masonry mesh and plastic umbrellas when used as the insulation of foam or EPPS.

The insulation material is fixed on the wall using umbrellas, and the grid is attached to them with metal stripes, screwing into the self-tapping screw. Their length should exceed the thickness of the insulation.

In some cases, instead of a masonry grid, it is possible to use leaf steel production waste - pressing. It is especially good for these needs a stainless steel suitable, however, it meets much less.

Facing the walls of brick is not a complex, but requiring care process. To present it better, watch the video: