How to choose a sandwich panel Building materials

Sandwich panel is a universal product that is simply indispensable in modern construction. This novelty has unique properties and excellent characteristics: panel sandwich are durable, not too heavy, they have a high bearing capacity, their installation is not possible, since everything happens quickly and conveniently.

Content

To all of the time, the panel sandwich has a big sound and thermal insulation, do not let moisture, are fire-resistant, and from above covered with reliable anti-corrosion trim. That is why the production of sandwich panels is currently experiencing a real peak of popularity.

What is a sandwich panel

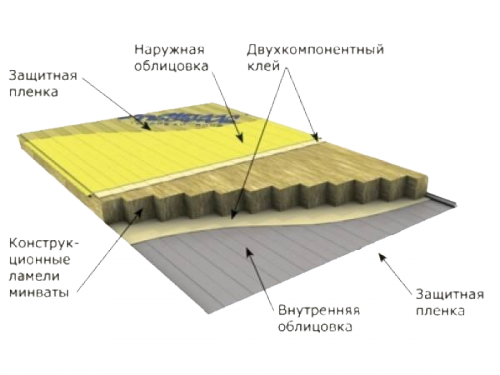

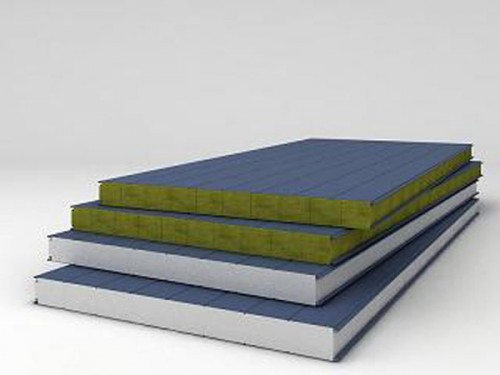

Sandwich Panel (from the English word "Sandwich", which means "multilayer sandwich") - this is such a building material that has a complex three-layer structure, which includes two sheets of hard material (for example, PVC, magnesite stove, metal or dvp) as well as a layer with insulation (between hard material). Details of the sandwich panels are glued together. Most often - with pressing with a hot or cold way. By appointment, they are divided into wall sandwich panels and roofing sandwich panels.

Basically, these materials are used to build frame houses, which relate to rapid displacement structures. From the sandwich panels build various trading facilities and office buildings, agricultural and storage facilities, production complexes, etc.

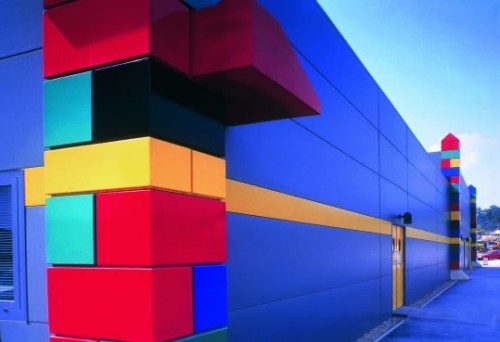

Due to the wide selection of colors and types, as well as the skin profile, it is possible to recreate the original architectural details and building projects. In addition, the panel sandwich is often used to restore and reconstruct facades, as well as simply as a heater for buildings.

Sandwich Panel Buy today is not a problem - good, there is a lot of firms that are engaged in the production or sale of various building materials.

What is worth paying attention to when choosing a sandwich panels

The popularity of the sandwich panels is definitely in their multi-layer composition. And it is the "internships" of the panel sandwich, the price of this building material is determined.

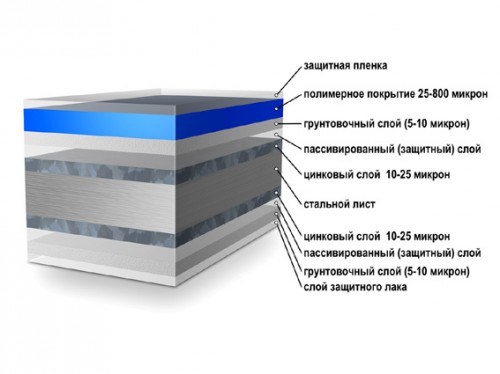

First, the cost depends on the insulating-structural filler, and secondly, from facing profile trim. Most often, sheathing is a sheet steel with a protective polymer coating.

As for the filler, there are many options here, as it must perform, first of all, its direct task is to ensure thermal insulation, as well as noise and sound insulation.

"Internships" can be made of polyurethane, polyisocyanurate, rigid mineral wool or expanded polystyrene. Due to the polymer coating, steel sheets are protected from various harmful effects from outside.

- Polyester (PE).

- Plaserisol (PVC).

- PolyvinylCheldluoride (HIARC).

As for the inside of the sheets of the sandwich panels, it is also covered with a protective layer, which increases the adhesion of both the sheath and filler.

How to choose a cover for sandwich panels

The sandwich panels are just an ideal solution for those buildings where the facades require significantly "spend" to good thermo- and sound insulation. In addition, these panels can also be used for high-rise buildings, as they have a greater permissible length of the span between supports.

The sandwich panels can be made from PVC, GVL, DVP, CSP, waterproof plywood, metal and other materials. If you are going to build a house, it is worth paying attention to the structural heat-insulating panels SIP - they consist of two OSB (oriented chipboard), and between them - a layer of solid expanded polystyrene.

The main difference between these OSB plates from other types is that, thanks to the strength properties and the ability to retain fasteners, there is not so much the presence of a binder as the character of the chip distribution.

OSB plates consist of a layered cross-oriented chip, the length of which is not more than 14 cm. This material combines high rates of strength and elasticity, so screws hold no density of the binder, namely by numerous thin chips that are oriented in the plane perpendicular to the axis of fasteners .

Due to the small dimensions of the SIP modular panels (1.22x2.44mm), these panel sandwich have dimensions that are just suitable for the construction of walls, creating overlapping and installation of roofs.

How to choose a filler for sandwich panels

Is it possible to achieve high thermal insulation and the absence of moisture permeability? Of course. A very well established such a filler for sandwich panels, like polystyrene foam, because he, working as a sieve, passes the air, but does not miss moisture, so condensate is not formed inside. Due to this, even in a wooden house there will always be air dry and clean.

The polystyrene foam will ensure the absence of moisture in the house, therefore, it will be possible to forget about the dampness forever, and hence, forget about mold, fungi, rot, etc. In addition, it is worth noting that the polystyrene is served for more than forty years.

As for fire safety, it is mainly used for the manufacture of sandwich panels. Even if the inner walls are finished with a layer of plasterboard, even then the limit of fire resistance of all designs to exceed 45 minutes.

Due to the high strength and rigidity of the sandwich panels, they can be used as carrier and enclosing items. Moreover, they have proven themselves in buildings located in seismic and tornadobic areas.

It is worth paying attention if you choose a panel sandwich for:

- External walls.

- Inland walls.

- Ceilings.

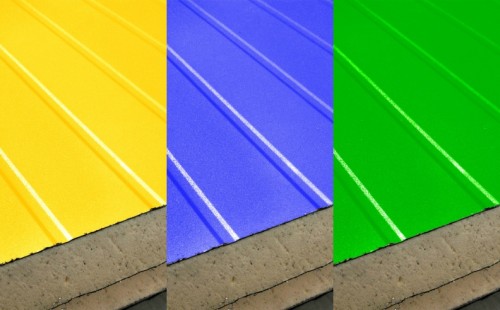

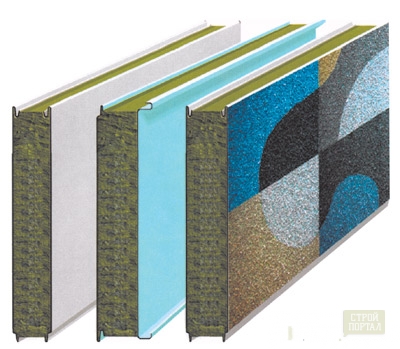

How to choose a color sandwich panels

The color of these building materials depends on paint, which is used for the outer layer. Basically, polymer coatings are used for these purposes - they are distinguished by increased resistance. In addition to aesthetic characteristic, paint is able to protect the material from adverse climatic influences.

Sandwich panels are painted in the factory. Due to this, it is also possible to significantly reduce the commissioning of the building, as there is no need to spend time on the additional interior decoration. In general, the choice of color depends only on the buyer's taste.

Due to the variety of colors of sandwich panels, which can be seen below, everyone can choose materials that will satisfy even the most sophisticated taste. There are more than two thousand colors and shades.

Here are some rules:

- If you need to create a relaxing and pleasant atmosphere, it is worth choosing warm shades, which, moreover, visually increase the room.

- Warm shades are better used for offices and working areas.

- Do not choose bright screaming colors for a small room - they visually reduce the area.

- For the finishing of a private house you can use blue, blue and green shades for sandwich panels.

How to choose the texture of the panels sandwich

Today you can choose a sandwich panel and in fact - many manufacturers have begun to provide such an opportunity for these eliminates. Earlier popularity used sandwich panels of a smooth structure. Today, more and more buyers pay attention to the rough texture.

Often you can see a sandwich panels that mimic a pattern of a tree or natural stone. This type of finish is not only a very aesthetic, but also a rather long-life option, because the dense coating layer effectively resists the effects of moisture, temperature differences and mechanical effects.