How to make a ladder formwork Ladder

When building a house consisting of two or more floors, you will inevitably reach the stage when it is necessary to build stairs leading from the floor to the floor, as well as in basement. The most reliable is the monolithic staircase structures, but they are quite difficult to erect. It will be necessary to formube for a concrete staircase, which will have to do it yourself.

Content

- What is the monolithic staircase, its advantages and disadvantages

- Types of monolithic stairs

- Formwork for monolithic stairs, materials and tools required for its assembly

- Formwork assembly technology for marching staircase

- An example of mounting formwork for the stairs do it yourself

- Scirat staircase formwork

What is the monolithic staircase, its advantages and disadvantages

The monolithic staircase is poured at a time, there are no seams that could make the design weaker. Such stairs are universal: the indoors are equally used in the same way, and on the street, and for the entrance to the basement or in the attic.

The advantages of the monolithic staircase include the following properties:

- strength and long service life;

- lack of screens;

- the ability to effectively use the premium space;

- ability to use with any climate;

- infertility of the action of a chemically aggressive environment;

- you can start using the staircase already at the construction stage of the house;

- fire resistance, fire safety;

- the ability to embody any designer projects;

- you can apply any finish.

But such a design has several drawbacks:

- the installation process is very laborious and takes a lot of time;

- high weight and, as a result, a serious load on overlappings;

- the presence of "wet" works.

Types of monolithic stairs

Depending on the position of the monolithic stairs occupied in space, there are:

1. Marshams. They consist of marches divided by intermediate sites. Marsh stairs may have different shapes, be g-shaped, P-shaped, curved, etc. Such stairs in turn are divided into:

- single-sample;

- two-hours;

- multi-hour.

2. Screw. Such stairs consist of steps or arranged around the vertical support, or resting in one end into the wall, and by the other, forming a vertical tunnel leaving up the helix. In this case, the screw radius can have both round and square shape. Screw stairs are not as convenient to use as marches, but they look very effectively and help if it is necessary to save free space.

Formwork for monolithic stairs, materials and tools required for its assembly

To make a monolithic staircase, it is necessary to make a formwork for it. The formwork is a design of parts connected to each other, which serves as a peculiar form for casting monolithic concrete structures.

From how correctly and qualitatively assembled formwork for the stairs will depend on its service, aesthetics of appearance and reliability.

Depending on the location and shape of the staircase, the formwork is manufactured or separately for each step, or entirely for the entire staircase.

For the formwork of formwork, consumables will be needed:

- edged boards 30 mm;

- water repellent plywood 20 mm;

- ribbed reinforcement 10-20 mm in diameter;

- brux with a cross section of 10x10 cm.

The formwork has the following detail:

- slices of bars connecting parts of the structure with each other;

- bars connecting parts for the formation of steps that prevent stretching of sheets during the fill of the solution;

- formwork for ends, made from plywood according to a predetermined pattern.

All parts of the formwork design must be perfectly docked and fitted to each other. The presence of cracks and recesses are unacceptable.

The formwork assembly is carried out using self-samples. It is not worth applying for this. Viewing the design, you will inevitably encounter difficulties in extracting them. To facilitate the process of connecting elements with each other, small bars and metal corners are used.

For work, you will need such tools:

- building level;

- plumb;

- hacksaw or electric jigsaw;

- a set of screwdrivers or a screwdriver with a bit of bit;

- hammer.

In order to do not get injured while working, you need to monitor the condition and serviceability of the tools.

Installing backups We must not forget that the concrete weighs a lot. Racks of the finished formwork before the fill of concrete must be installed on the floor, but in no case do not hang in the air. To prevent such a situation, the wedges are driven under the racks or links are installed. To increase the stiffness of the structure as a whole, it is associated with boards around the perimeter.

At the last stage of assembly of the formwork design, reinforcement. This is done to increase the strength characteristics of the formwork. Most often for this applies ribbed fittings. Her elements twist with each other soft wire.

As mentioned above, the monolithic staircase is poured with concrete at one reception. You should start from the bottom stage, moving gradually upwards. In order for the solution, the crushed stone is mixed into it. To prevent the formation of air cavities in the concrete, it is mandatory to use an electrovibrator. After the concrete freezes, the formwork is dismantled and starting the staircase.

Formwork assembly technology for marching staircase

The formwork for a straight march is assembled as follows:

- on two side boards width in 20 cm place future steps;

- guided by this marking, navigate the bars to which the risers will be reigned;

- if the stair march is not wide, then 40 mm boards in thickness will go to the formwork for risers. In this case, use the board in the middle is not necessary. But when used, you need to fix it with its help additional stops;

- before pouring concrete, stakes are driven into the ground, and after the pouring is left in solution. When he freezes, the protruding ends saw off;

- regardless of the cladding selected for steps, the formwork is made of standard height.

An example of mounting formwork for the stairs do it yourself

This example concerns a stair construction located between two walls standing against each other:

- focusing on the draft prepared in advance, mark both walls, between which the staircase will be placed. Place the markup in a fat marker and do not forget to take into account the thickness of the facing material for steps;

- attach to the concrete wall 12-15 centimeter nails associated guides for formwork. Install the racks, resting them into the concrete, take the wedges below them. To the wedges, make the struts and attach them with self-drawers;

- because Guides are hard to fix on the wall, they will also fasten with struts with struts;

- make a formwork from the boards, laying them on the edge of the guides, born earlier. Place the roofwork on the surface of the formwork, secure it with the brackets, and the sharp corners of the boards are polished;

- after that, reinforcement should be reinforced. Drill holes in the opening and score reinforcement in them. Attach additional bars to them, twisting them with wire;

- next, assemble the formwork of steps. To do this, we must take the boards as the width as the height of the risers and attach them to the wall with the help of a dowel;

- the right side of the formwork design is attached to the intermediate crop with self-draws and tin corners. The intermediate detergent is fixed on the wall by means of 15 centimeter nails;

- throughout all the work, check the position of the planes by the construction level. Next should be poured with a solution.

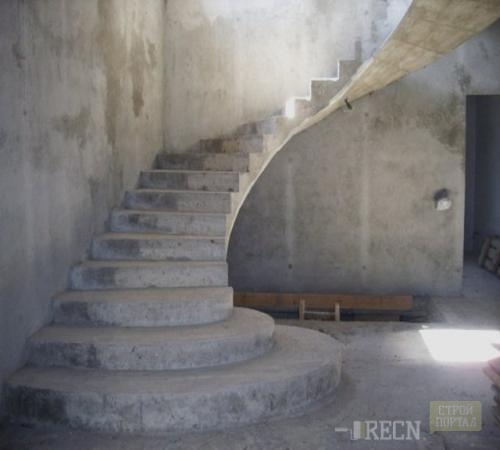

Scirat staircase formwork

The formwork for the screw staircase is formed by the same principle, but the assembly of it is much more complicated. Each element has to be made separately. For this, the sheets of plywood in the form of a trapezium are used.

On the sides, the curved surfaces are mounted or from the boards, or from the same plywood. To increase the stiffness of the structure, it is enhanced by racks from bars with a cross section of 100x100 mm, having them with an interval of 40-60 cm. The mount should be reliable. The design is supported by stars in such a way that the weight of the formwork and reinforcement accounted for a bar. To calculate the number of required backups, it is necessary to estimate how much the entire concrete structure will weigh, considering that the 3-meter bar 100x100 mm can withstand the weight of about 150 kg. To enhance the stiffness of the structure, the support racks are connected by transverse crossbars.

Before filing with a solution of formwork for a staircase, you need to install special plates to which the railing will be attached.