Formwork for the foundation of the fence with your own hands Construction

Formwork for the foundation of the fence is an integral element in concreting design. Without it, the concrete solution will not qualitatively. About nuances of making formwork and will be discussed in our article.

Content

Varieties of formwork

There are several types of structures that depend on the material used. Main types of formwork:

- Horizontal. It is advisable to use when bookmarking a massive foundation.

- Vertical. When light material is used.

- Inclined. Under the device of non-standard design. It is rarely used.

Also formwork happens:

- non-removable;

- removable.

A non-removable design is made from long blocks (usually used sheets of metal or plywood) with side restrictive shields and metal ties that connect all elements of the formwork. Removable formwork for the foundation under the fence is made of bonded boards, which are easier to dismantle.

What kind of design would not be selected, it is recommended to adhere to such requirements when it is recommended:

- creating smooth corners;

- lack of warming elements;

- as close as possible fasteners;

- the optimal thickness of the material (it must withstand the full load);

- if necessary, the formwork should be easily dismantled.

Design Material Material

To create a formwork, you can use various materials:

- wood;

- plywood;

- reinforced concrete;

- metal;

- polystyrene foam.

With wood and plywood everything is clear. Such a formwork for the foundation of the fence is the most common option. This is due to the availability of material, the minimum cost and inappropriateness to use special tools.

The use of constructs from reinforced concrete will reduce the need for concrete solution. For laying plates that have solid sizes, a small amount of concrete will be spent. "Minus" of such a formwork is a lot of weight and installation of additional struts.

The formwork for the foundation of the fence made from metal sheets will be very high. But this is the only drawback. From positive qualities, high insulation properties should be noted, the possibility of welding the frame and flexibility of the material.

Polystyrene foam is one of the best options for arrangement of formwork. This design is easy to assemble. You just need to fix blocks with each other. The polystyrene formwork is excellent with waterproofing and easily acquires the desired configuration.

Mounting work

The device itself is the formwork for the foundation of the fence with its own hands, it consists of four main steps:

- marking of the territory;

- riveting trench;

- installation of support columns;

- fastening shields.

Placement work

At the initial stage, the size of the formwork is determined. It usually its width is 0.4-0.5 m, the height above the ground surface is 0.3-0.4 m, the depth is up to 0.6 m. The boundaries of the fence are drawn by a shovel or by pulling the fishing line. It should also be noted the places where the support columns will be mounted.

If communication, large stumps or other barriers come across the perimeter of the fence, then it is better to get around them. The presence of small drops should not disturb, as it is leveled by creating a reliable design.

Digging trench

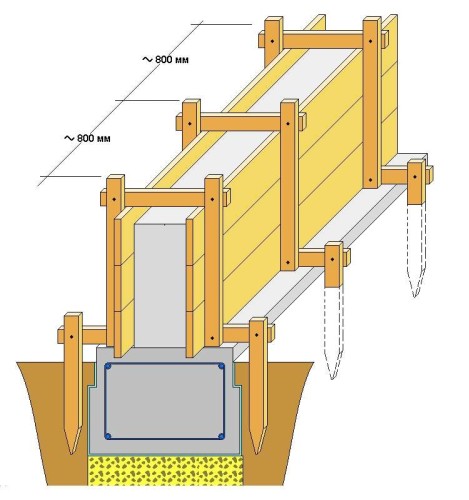

This procedure provides for the creation of a trench, which has a solid reserve on both sides. For example, with a formwork width of 0.4 m, the ditch width should be at least 0.7 m. This is due to the fact that the side bars of the shields will be in a soil by 0.3-0.4 m.

The seizure of the soil is carried out according to the markup. In places where the installation of columns will occur (usually in the wall of the trench), additional holes are made to 0.2 m.

Installation of support columns

The optimal step of installation of columns is 1-1.2 m. The upper part of the bar is towers above the ground surface by 30-35 cm. The mounting of the columns is carried out in such a way that on one side of the trench they fit in the middle between two columns located on the opposite side.

When installing bars, it is impossible to allow the appearance of distillauses. Otherwise, it is fraught with a decrease in the strength qualities of the raised formwork for the fence.

Fastening shields

The most popular is a formwork made of wooden shields. The design of plywood is widely used.

On the columns installed on both sides of the trench, the plywood sheets are attached. They are placed in a strictly vertical position. For a reliable fastening of plywood to a wooden bruse, self-sufficiency or nails are used.

For high-quality creation of formwork for the foundation when attaching shields, such recommendations should be followed:

- between the lower part of the shields and the bottom of the trench should not be gaps;

- the fixation of plywood is carried out in the inside of the ditch, and the columns are per shields;

- screw screwing is made at an angle of 45º;

- to enhance the design, fit fittings.

After installing shields, formwork is tested for strength. If necessary, the design is strengthened with metal corners or by screwing up additional screws. Immediately mounted pillars on which the fence will hold.

After creating a formwork is carried out concreting foundation. After grapping the concrete solution, the removable formwork is subject to dismantling. This process is made in reverse order.

Video on the creation of formwork for the foundation of the fence: