Substrate for a parquet board. Features of choice Floors

When decorating different rooms in his own house, one of the first urgent questions - how to choose a coating that will serve for a long time and will become an excellent addition to the general artistic picture of the room. Thanks to excellent technical specifications, natural beauty and environmental cleanliness, a parquet board is used by permanent demand, which allows you to bring so necessary comfort, but with this nuance of elegance and solidity. To mount such a floor covering correctly, it will be necessary to choose a substrate for a parquet board, which would be perfectly combined with the terms of the room. How to do this, you will learn from this article.

Content

Purpose of the substrate

To understand why you need to buy a substrate for a parquet board, read its functional purpose and the capabilities that are as follows:

- the substrate creates additional noise insulation, which prevents the propagation of noise from vibration when working with household appliances, as well as when walking on floor coating;

- the possibility of eliminating small repair defects, in particular, alignment of the base;

- protects the floorboard from excessive temperature drops and humidity, which destroyably affect wood, as it provides additional heat insulation from roughing;

- qualitative redistribution of the load throughout the coating, which contributes to a longer service life of the parquet board.

Criteria for selecting a substrate for a parquet board

The main criteria for selecting material are:

- conditions of operation of a particular room, in particular, humidity and temperature;

- the cost of the parquet board;

- the thickness of the substrate under the parquet board;

- environmental purity;

- specifications and method of laying a specific type.

Important! All substrate parameters must also match the level of your professional skills, if you decide to make stacking yourself.

What material to choose a substrate?

Today, today is a fairly large variety of materials of this purpose, among which there are developments from different manufacturers in the following categories:

- polyeneetylene;

- cork;

- painopropylene;

- foil;

- composite;

- software substrate over parquet board.

Important! Depending on the form of release, the main material and thickness will vary and the price of a substrate under parquet. Therefore, when choosing, focus on the appropriate complex characteristics of the material, as well as on its cost, since when laying a cheap parquet, acquire an expensive substrate at least inappropriate. It, of course, will somewhat extend the service life, but will not be able to greatly increase the technical characteristics of the planks themselves and the quality of wood.

Polynevenient - pros and cons

The substrate from such a material has many advantages:

- resistance to pathogenic bacteria, fungi, mold, which eliminates completely harmful effects per person;

- resistance to mechanical damage to rodents and insects;

- moisture resistance;

- good thermal insulation properties;

- chemical stability, for example, to oils, solvents, and even to aggressive alkaline effects, which allows the use of polyethylene for laying directly to a concrete or cement base;

- low price.

Important! As a lack of such a material, only its possible destruction is distinguished in constant exposure to ultraviolet. Also, with long-term operation, there is a loss of elasticity, which can lead to the flexing of the flooring. It is impossible to lose sight of that this kind of substrate synthetic origin.

Features of laying

This option of the substrate is used if the installation of the parquet is made online. Polyenethylene strips are laid by strips throughout the area of \u200b\u200bthe room, after which they are fixed using assembly tape.

Important! A lot of modifications of the polyethylene substrate are presented on the market, but the material is suitable for the parquet, 2 mm thick.

Foamed propylene: advantages and disadvantages

This species is the most fiscal of all existing. Among the advantages of its use, you can highlight such characteristics as:

- a porous structure that provides high-quality heat insulation and breathability;

- good noise insulation;

- reliable protection against condensate, which can accumulate on the surface of the draft floor.

But, propylene has a number of flaws that make it far from the best option for laying a substrate under parquet:

- high susceptibility to burning;

- a higher toxicity rate than all other groups of materials of this destination;

- a short service life - after 7, a maximum of 10 years, such a substrate is scattered into a duch.

Fungalized substrate

This material also relates to a group of propylene substrates, since it is propylene that is the main component of its composition. Due to the addition of a foil layer, undoubtedly increases all the qualitative characteristics of the previous version, and the adverse effects are somewhat reduced. In essence, the foil substrate is an improved version of cheap propylene material.

Cork substrate: species, advantages and disadvantages

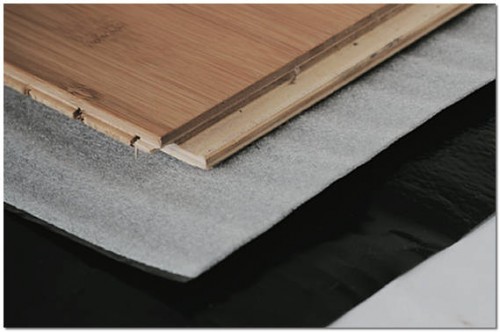

The cork substrate under the parquet board is the optimal solution that is the traditional way to arrange wooden floors. Its production is carried out by pressing the pre-crushed wood of cork oak. This substrate is produced in several forms:

- rolled coating, from 2 to 8 mm thick, the length of the canvas is 8-10 meters;

- tile cork substrate, the thickness of which varies in the range of 1-5 mm, and the standard parameters of the modules - 60 * 60 or 60 * 30 cm.

Depending on the component composition, the cork substrate happens:

Advantages and disadvantages

The advantages of such material include such characteristics:

- high strength;

- long-term operation;

- environmental purity;

- resistance to rotting, mechanical exposure;

- long-term preservation of all specifications;

- elasticity and excellent depreciation property, due to which the floor saving is excluded with time;

- the ability to eliminate the fairly large irregularities of the floor when laying a parquet board.

Important! As a lack of an ordinary cork substrate, its increased moisture absorption is distinguished, which is why it is recommended to use it for premises with a lack of drops and a stable reduced level of humidity. Given this fact, when decorating the floor with a cork substrate based on a concrete black floor, an additional consumable material is required - a waterproofer with a thickness of at least 1.5 mm, for example, a polyethylene film.

Bituminous and rubber plug: differences

These varieties of cork substrate are distinguished by the fact that they are not amenable to adverse effects of condensate and other moisture forms. Bituminous-cork material is based on kraft paper, impregnated with bitumen and crashing cork chop. The rubber-cork substrate is manufactured by mixing polymers, cork crumb and rubber granulate.

Important! The additional advantage of the rubber-cork material is the maximum soundproofing efficiency at which 100% silence can be achieved.

The fastening of these materials is embedded, but there are certain requirements for the width of the fastening tape - it should be at least 5 cm.

Important! Bituminous and rubber substrates are an innovative solution and are far from all manufacturers among the range. Find these species from the Parkolag manufacturer.

Composite substrate

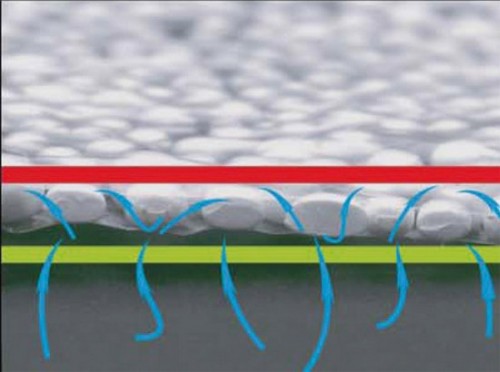

The main difference of this material is a multicomponent composition. As a rule, it consists of several layers - at least 3, the extreme of which is drawn up with a polyethylene film of 2 different compositions, and medium-granulated polystyrene foam. Such a structure provides high-quality ventilation of the floor covering, that is, condensate does not accumulate and the flooring is not yet destroying.

Important! Separately, we note that the material is very thin, despite its multi-layeredness - about 3 mm. The substrate is most in demand under the Tuplex Parquet Board, the quality of which is checked by many consumers. How to properly carry out its laying, see below the proposed video.

Coniferous substrate

Such a type of substrate is one of the most expensive options, but its effectiveness pays off when laying as expensive parquet.

The advantages of the coniferous substrate are as follows:

- environmental purity of natural wood;

- excellent strength and wear resistance inherent in all coniferous rocks;

- high-quality noise and thermal insulation;

- optimal density, which eliminates the deformation and sagging of the floor after a certain period of operation;

- resistance to adverse effects of moisture.

Important! Separately, we note the maximum convenience of mounting. In the market, the coniferous substrate is represented as a modular tile material, which is easily laid with minimal costs and time and is not deformed when mounting. And for this you do not need professional construction skills.

Conclusion

As you can see, the range of such auxiliary consumables, as a substrate under a parquet board, is quite wide. Nevertheless, it is not difficult to make the right choice, if you define your requirements in advance and accurately designate the conditions for the intended exploitation. When you buy even the material inexpensive category, give preference only to proven brands so that the substrate does not live in the specified period of time, and did not cause the destruction of the floor and the need for repair work was previously deadlines.