How to make a concrete staircase. Concrete staircase with your own hands Ladder

Concrete staircase is a standard building structure present in all multi-storey buildings. It serves for safe and comfortable movement between floors. An external or inner design, made independently, optimally fit into the interior of a modern building, such as cottage, cottage or residential building.

Content

Design species and formwork type

The most time-consuming stage for the formation of a concrete staircase is the installation of formwork. Since it is from her that the symbol of the construction of the ladder will depend. And the design of the shape depends on the staircase and its geometry.

Intermedirate design

Light in the version of the concrete staircase in private houses is the type of construction when it is placed in the opening of the walls. With this installation form, you can outline the contours of the staircase, going around without side formwork. This type of staircase allows you to successfully fix the components of the form directly to the walls. To do this, on the side surface, wooden bars, which serve in order to make the board are mounted. After that, the boards are fixed to the walls of steel corners to create steps.

Construction of a rectangular profile

A relatively simple formwork type is a single-sample design with a rectangular profile. This option involves the creation of the end surface of the shape, which is fixed on the supports.

Simple geometry of this design provides sufficiently blatant formwork. And the aesthetic expressiveness and decoration of the concrete staircase is provided by the unusual railing, decorative design, as well as the original steps.

Spiral staircase design

Concrete stairs in the form of a spiral structure are the most aesthetic and expressive. But the complexity of the formation of such a structure is that it will require non-standard types of shields. As a result, high costs of labor intensity on the production of sheets and their fixation will be required. But in mind the complexity of the form of a staircase, to impart stability, the installation of a complex reinforcement framework is necessary.

Calculation of monolithic stairs

Before the start of the building process, it is necessary to measure the space of the staircase, make the project sketches and draw the size so that the concrete ladder is comfortable in use.

The fundamental parameter in the formation of the structure is the angle of raising the stairs. To do this, take into account:

- sizes of a staircase;

- convenience;

- the complexity of the formwork creation.

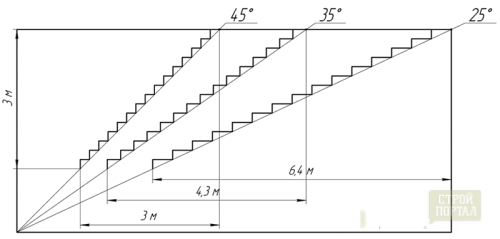

For internal structures, the optimal angular point of lifting is the indicator of 25 ° - 45 °.

The figure clearly shows how the angle of the staircase influences the dimensions of the design. when calculating the concrete staircase. The projection of the staircase, with an increase of 45 °, will be 3 m. For a ladder with a rise of 35 ° height to increase to 4.3 m, and if the angle is 25 ° - the projection will change the position to 6.4 m.

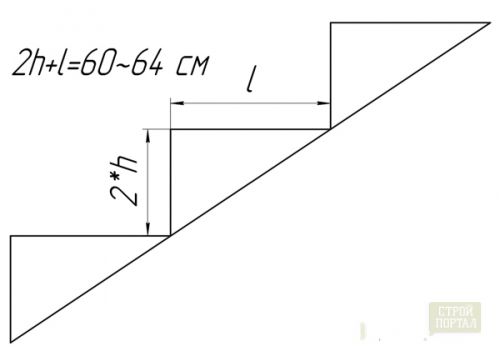

After the correct choice of the angle of the staircase, it is necessary to calculate the optimal parameters H and L-highness and the width of the steps, respectively. To derive these indicators, there is an equation based on the average length of the human step - 60-63 cm. To build a convenient design, it is necessary to calculate the parameters according to the formula:

2 * H + L \u003d 60-63 cm.

Montage of the formwork of concrete design

The formation of the stairs begins with creating its form - formwork. The strength of the construction affects the reliability and appearance of the staircase. Most often, the formwork is made of waterproof plywood sheets or edged boards. How to show photos of concrete stairs , to prevent the leakage of the cement mortar, it is recommended to use a leaf fan with tight pressed boards.

At the initial installation stage, components will be required:

- waterproof sheet plywood or edged board;

- bruks, whose cross section is 100 × 100 mm;

For standard design, the plywood cross section should be within 20 mm, and the edged boards - 30 mm in the context. If the plan is planned to build the surface of the curvilinear type, then the boards and plywood sheets must respectively have a section of 15 mm and 9 mm.

Additional components for formwork:

- bruks serving to fix the components to the walls;

- bruks designed to connect forming steps and avoiding deformation during concreting;

- face elements of formworks, which are made of sheet plywood with the necessary dimensions of the steps.

The optimal solution for fixing the components of the formwork is the tapping screws that have a diameter of 3.5 mm, since when dismantling, the extraction of standard nails will be difficult. Also additional elements that may be required when forming formwork are perforated corners.

It should be borne in mind that to prevent absorption fluid from a solution into a wooden formwork, it should be missed by oil paint. On the sides of the form it is necessary to provide wooden stakes for the backups that will help the designs are not deformed during concreting.

Installation of reinforcement carcass

The next stage of the construction of the concrete staircase is the creation of a frame of reinforcement, which will serve as a strengthening design for the installation of concrete stairs.

To create a frame, it is necessary to put steel rods along the support faces and combine cross-links together. For greater reliability, it is recommended to fix the reinforcing frame by arc welding tools. However, if there is no such possibility, then you can apply a wire designed specifically for knitting, and how to use hooks as a connector. They must be pre-clamping the screwdriver.

In order to comply with the norms of the required distance between the lower part of the form and the reinforcement, it is rationally to apply a special plastic fastening.

Also, the reinforcing frame along the length of the span should be fixed with the wall. Therefore, it is necessary to drill the holes of the desired diameter in the wall, and then score pins with a hammer.

To ensure the grooves for the future fencing of the staircase, you need to mount the mortgage tubes from the tree. Metal plates can also serve. After that, you can start concrete work.

Concreting stair construction

One ladder flight should be concreted into one approach, starting work with the steps of the lower row. In order to avoid unwanted mobility and leakage of the solution, it is necessary to add large crushed stone into the concrete mass.

The concrete brand recommended for the manufacture of concrete stairs is B15 or higher. Also, for the stability and reliability of the structure, it is necessary to take into account the method of sealing the concrete mass, since at 1% underplication of concrete, the strength of the structure is reduced by 7%. In this regard, the work on rubbing is best carried out with the help of a construction vibration machine. In the process it is worth avoiding the touch of reinforcement, as this can provoke the appearance of cement "milk", which reduces the grip with the frame.

The composition of the concrete solution in liters is: 4 rubble, 2 sand, 0.6 water, 1 cement of the brand of PC-400. You also need to add a plasticizer in an amount of 10 ml. Stir the solution is recommended in the concrete mixer, because Even with the diligent stirring of the solution manually, the strength of the mass is reduced by 20%.

Sequence of adding components:

- crushed stone;

- cement;

- sand;

- stirring the mixture to dry for 1 min;

- water;

- stirring solution for 2 minutes.

After concreting, it is necessary to cover the surface of the staircase with a polyethylene film, in order to avoid the rapid drying of the mixture. The facing of the concrete staircase is possible after removing the fastener. And to dismantle the formwork can be not earlier than 3 weeks under the conditions of hardening in room temperature.

See the phased process of construction of the concrete ladder here: