Ribbon Foundation Bookmark Technology Building materials

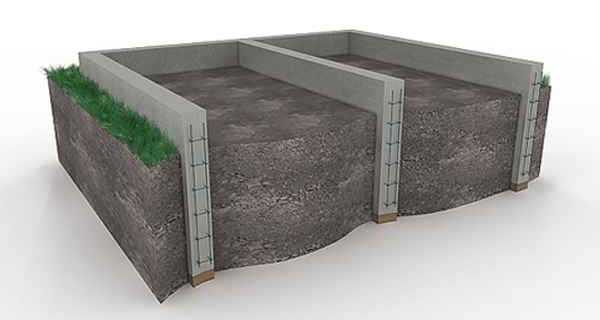

Ribbon foundation is the most popular: This type of base can be used to build various buildings. The bandmark of the ribbon foundation involves the device of a monolithic reinforced concrete structure around the perimeter of the building.

Content

In which case the ribbon foundation is preferable

The basis of this type is based on a mandatory basis for a number of cases:

- if the project provides a device of a basement or basement floor;

- for the construction of multi-level buildings with thick walls of brick, stone or concrete blocks;

- in the event of construction on a bulk or swampy soil, prone to chosen.

Criteria for choosing a place for the construction of the foundation

The right choice of space for the foundation is one of the main strength conditions of the entire structure. The survey of the site is performed at the preparation stage for construction, after the snow cover melts. The following factors are taken into account.

- The presence of soil festers, cracks and failures, which indicates the proximity of groundwater.

- In the zone of the spring spill of the reservoirs, a bandmark of a ribbon foundation should not be made. The base device must be planned at the highest possible distance from dangerous areas.

- It is recommended to see the foundations and basement floors of the structures built nearby at an earlier period. The presence of widespread cracks means that the soil in this place is not suitable for construction.

- The soil in the trench developed for the foundation should be homogeneous in composition. Wet soil is more prone to frighten than dry.

- It is important to know the level of soil freezing in a given area: the depth of the ribbon foundation should exceed this value.

- Relief surface: It is recommended to choose a horizontal, smooth area.

Tip: For professional assessment of soil, you should use the services of specialists of the hydrogeological enterprise. This will help correctly determine the depth of the base laying.

Material for construction

The ribbon base can be erected from the following materials:

- concrete monolith with reinforcement is the most durable foundation, which is at least 150 years;

- bud foundation - also serves about 150 years;

- the base of ceramic brick - the service life can be about 50 years;

- the design erected from concrete blocks is not less than 75 years old.

Tip: When erecting a foundation from ceramic brick, it is recommended to choose the cheap. Such a brick lies longer in the ground, thanks to a higher density.

Construction of belt foundation

Distinguished tape foundations of monolithic (concrete) and prefabricated, elevated from brick or concrete blocks. For laying blocks, a lifting equipment is necessary, and the monolithic base is manufactured directly at the construction site.

Depending on the calculated load, tape foundations are constructed by two types.

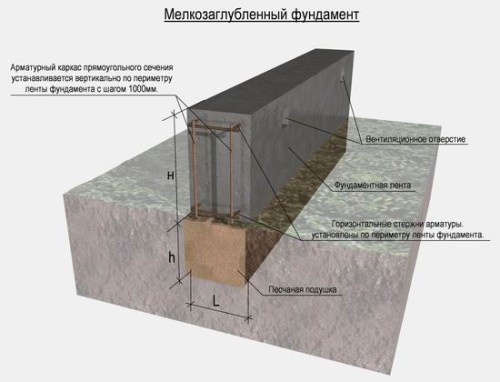

- Small-breeded monolithic foundation: constructed throughout the perimeter of the structure for uniform load distribution. Such a base is optimal from the point of view of savings. At the same time, the construction of the building should be as easy as possible. The small-breeding foundation of this type is suitable for the construction of single-storey brick, wooden, frame and block houses. The depth of its embezzlement is 0.5-0.6 m.

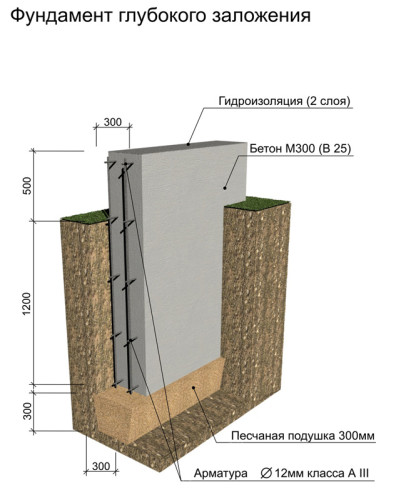

- Outfolded foundation: used for massive multi-level buildings from brick and stone with concrete floors. Such foundation is of greater durability and stability than the finely breed. The base of this type can be monolithic and composed of separate concrete blocks bonded by cement mortar. The depth of the foundation should be lower than the level of primer of the soil in this area, usually 1.2 m or more.

Bandmark of the tape foundation: The scheme of a fine-breed device

Scheme of a rural base

Ribbon Foundation Bookmark Technology

The process of erection of a belt monolithic foundation can be divided into several stages:

- preparatory work (cutting down of trees, playground alignment);

- markup;

- digging trench;

- installing formwork;

- reinforcement;

- pouring concrete;

- waterproofing;

- reverse swelling soil.

Preparatory work and markup

At this stage, the following steps are performed.

- In the construction site in the zone of the foundation and at a distance of at least 5 m, trees and shrubs cut down from it, sniffed stumps. You must also remove the turf.

- Playground allotted for construction should be aligned. The soil is evenly distributed on the territory, there is a swing and tamper.

- Marking for trenches under the foundation is performed using wooden stakes and cord. Pre-using roulette make measurements on the ground. The stakes are clogged into the ground in the outer angles of the future structure, and the cord is stretched between them.

- Delivery of building materials: First you need boards (plywood) for formwork and sand for a submet.

Digging Trench, Formwork Device

On the contour of the markup manually or with the help of special equipment, the trench of the required depth is rotated. The width of the trench should be a slightly greater width of the future base of the house. The bottom is aligned horizontally and compacted. After that, the following is performed.

- On the bottom of the trench, the subference from the sand (300-350 mm) is stacked, which is wetted and thoroughly tamped.

- Waterproofing material is stacked over the sandy subfolder.

- Formwork is built from board or moisture resistant plywood. Its edges should rise above the level of the ground at least 150 mm. Formwork walls must be strictly vertical.

- The upper edges of the formwork are connected by jumpers and are strengthened with pins.

Boards are connected by self-drawing and nails. To enter communications, leave the holes.

- The inner walls of the formwork are lined up or rubberoid.

Important: the gaps between boards or plywood shields should not be, otherwise the cement solution will flow out. The struts and wedges should be installed at least 0.5 m: This is important for the formwork strength, which should withstand the mass of concrete.

Reinforcement of foundation

For reinforcement, it is necessary to use fittings with a diameter of 12-18 mm. It is recommended to follow some rules.

- Stacking reinforcement is performed along the trench in several rows, forming two belts. The lower belt should be at a distance of at least 40 mm from the sandy submet, the upper - at the same distance from the top edge of the formwork.

- The rods are associated with a soft wire in the crossing places.

- In the event that the project provides insulation of the base, from the outside of the formwork, instead of the runner, the sheets of foam or extruded polyurethane foam are installed.

Pouring concrete

At this stage it is important that the whole process is made in one reception. Concrete M250 or M300 must be moderately thick fill rules as follows.

- Concrete is poured gradually, layer behind the layer. The supply from the hose should be carried out from a height of no more than 1 m to prevent the mixture bundle. It is recommended to use a gutter.

- After the fill every 150-200 mm, the concrete is sealing with vibropresses to drive out of it (in the case of formwork from metal sheets). When a formwork device from wood materials should be used to use a bayonet shovel: it repeatedly poured the mixture. Periodically climb the walls of the formwork.

- Pouring should be produced in the warm season. Otherwise, the concrete must contain special additives.

- To avoid cracking of concrete, it should be stolen from hot sunlight and periodically wet.

- The platform is performed no earlier than 5-6 days. Complete concrete hardened occurs within 28 days.

After dismantling the formwork, the lateral and outdoor side of the base are covered with bitumen and rubberoid. After that, they perform inverse sand dropping, and then soil.

Tip: To more efficiently protect the base from groundwater, the bandmark of the ribbon foundation (see the photo below) is performed in conjunction with the device of the drainage system.

Errors to avoid

So that the base, and with it, and the entire structure served as long as possible, with the construction of a ribbon foundation it is necessary to avoid the following errors:

- incorrect assessment of the soil;

- use of materials of improper quality;

- insufficient reinforcement;

- deviation of formwork from vertical;

- damage to waterproofing during reverse swelling;

- violation of the timing of solidification of concrete.

To avoid siblings, we recommend to familiarize yourself with how the tape-foundation is performed by professionals: video with comments.