Make the gate frame with your own hands Useful advice,Construction

Much depends on the choice of the design of the gate. First, this is how attractive and stylish the entire architectural ensemble will look. Secondly, it is convenience in operation. Third, reliability and durability. The gate frame made by independently will save at the cost of the entire structure. Constructed by its own hands the gate frame from various types of metal and wooden elements in the subsequent is trimmed with any suitable material. It can be a gate of a professional flooring, a wooden gate on a metal frame, frameworks, a chain chain chain or a metal stakenist.

Content

Types and types of gates

By types of gates are:

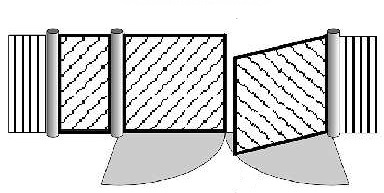

- Swing (The most acceptable option for the gate that do not require a wide space for skipping).

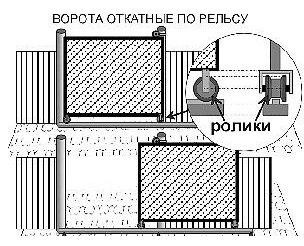

- Retold (on rail, suspended, etc., can provide a wide skip).

- Lifting (more suitable for garages and boxes).

- Other structures (for example: folding).

In turn, each type of gate can be divided into species determined by the capabilities of the type of construction, for example: swivel; vertically - lifting; sectional; roller; other species.

Design frame gate

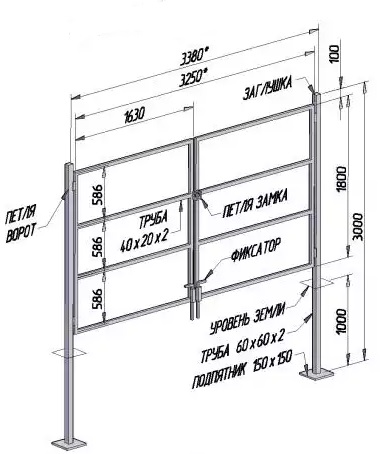

By selecting the type and view of the gate, you need to decide on the design of the future gate frame and draw a graphic drawing with the size of the sizes and the detailed display of each element.

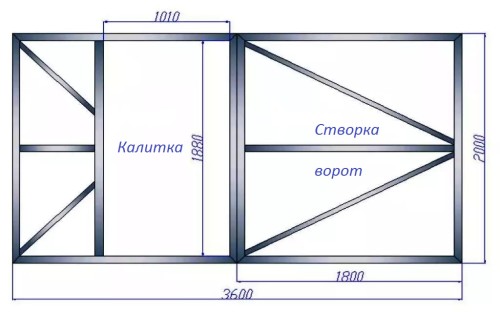

Drawing design framework

Graphic planning of the future design will help draw up an approximate estimate and will avoid many problems when implementing the plan.

Material selection for gate frame

As a material for the frame of swing and roll back, as well as the gate, a profile tube or metal (metal profile) is suitable.

Description Design Frame Gate

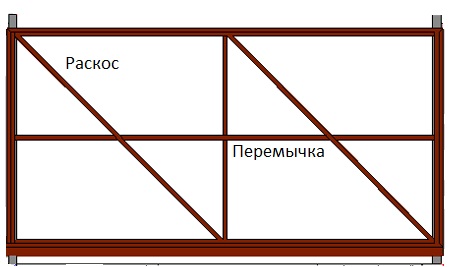

The frame design of the swollen gate is two sashs from the profile pipe with a cross section of 20x40 mm and more, depending on the width of the gateway and the material of the trim. The frame of the gate of the professional flooring must have horizontal jumpers and reinforcing debris flaps. For the subsequent framework of the frame with a tree, the profile tube must be selected with a cross section of at least 30x50 mm.

The total width of the gate, depending on the necessary bandwidth, is usually:

- For the passage of passenger cars - 2.4-2.6 m.

- For the passage of trucks - 3.2-3.5 m.

If necessary, you can make a swollen gate with one sash, if the total width is not more than 3 m. However, such a design will increase the load on the suspension and it will be necessary to strengthen it.

Folds are made from metal or wood frame from 1.5 to 2 m high and more. The frames are subsequently trimmed by any selected material. For a frequent passage to the design of the gate frame, you can turn on the gate, if this is not planned elsewhere. The wicket frame is constructed and manufactured according to the same principles as the gate frame, usually about 1 m wide.

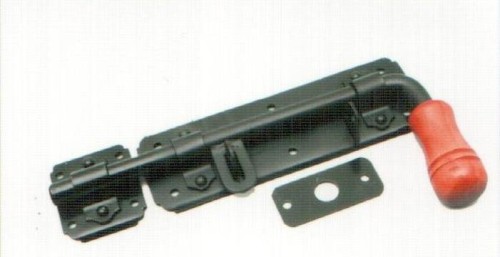

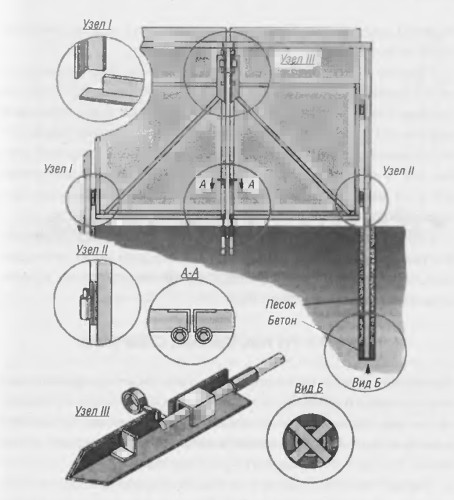

Also in the design of the swollen gate, it is necessary to provide loops for hanging on the poles at the edges of the opening and a valve or other type of locking device. Most often, loops of a barn type are used for the gate. Number of loops (usually 2 or 3 pcs.) Selected taking into account the weight of the frame along with the trim.

Loops for canopy frame on the poles, as well as hinges for the mounted lock and other locking devices can be purchased in the finished form. However, in the presence of the remaining material, you can make these elements of the gate with their own hands. So the lower valves can be made of a galvanized pipe 3/4 "or reinforcing metal with a diameter of 12 mm. For the upper valves, it is possible to use steel corner 32x50x4 mm and 25x25x4 mm, 3/4 "and 1/2" metal pipes and reinforcing metal with a diameter of 12 mm. Moreover, such valves are possible to lock on the suspension lock.

When designing a frame design of a swing gate, it is also necessary to envisage, in which direction the sash will be swollen. Here it will determine the presence of free space before the gate on the inner and external perimeter. For the sliding gate and this is their plus, this presence is not taken into account. The swords of the swollen gate should swing up 90 ° and more, which is taken into account when installing hinges for hanging.

When designing a sliding gate frame, it is necessary to take into account that the canvas should be tough and correspond to the weight characteristics of the future gate, as well as resist the wind without deformation of the structure. Therefore, as the basis of the frame is better to take a metal profile, and its diameter is more than the diameter of the jumpers, which will reduce the weight of the gate design.

Montage of frame gate

The main way of installing metal frames is welding. However, there are other possibilities for assembling frames, for example with screws or rivets.

Determining in the selection of the method of manufacturing a gate frame is the presence of appropriate equipment and tools skills. If the owner of the future gate design has all this in full, then a welding method is recommended. Welded frames are distinguished by increased strength, durability and practicality, as well as, which is important when choosing and installing pillars and mounted devices, a special ease of construction.

Before starting work, you need to cook everything you need. First of all, this is the material from which the future design is manufactured. Moreover, the material must be purchased with a 10-15% margin, in case of a possible marriage in operation.

Approximate list of necessary equipment and tools

In order to make a gate frame, you will need:

- Cornel, Roulette and Metal Marker for marking or chalk.

- Bulgarian with a set of discs for cutting and grinding.

- Protective gloves and glasses.

- Welding machine and welding mask (glasses).

- Set of electrodes with a diameter of 3-4 mm.

- Another tool with a caustic assembly method.

Next, it is necessary to prepare a working surface. To do this, the flooring is made from the board and levels along the horizontal level. After that, you can start making the frame.

Procedure for Mounting Gate Frame

To avoid unnecessary problems in the manufacture of a frame, you need to act in succession in the following order:

- In accordance with the graphic drawing, a pipe, a metal profile or other selected material is cut in size.

Cutting profile pipe with a grinder

An example of preparing a metal profile for docking

- The external frame of the gates and wicket flaps is manufactured.

Example of docking profile pipe

Example of docking profile pipe bolts

- Cooked (collected in another way) Rectangle must be checked by the coal. The diagonal of the rectangle must be equal, and all the angles are straight.

Checking the corners of the coal

- If the rectangle is correct, then the drives are joined, vertical and horizontal elements of the crate.

- Join mounted loops to the frame of the swollen gate.

Hinged loops

- If necessary, you can first put the sash to the post, on chocks or bricks, and place the fasteners.

- The gate valve is joined, the loop for the mounted lock or another locking device.

- The finished frame is ground and painted.

Fortress and painting frame