Metal fence of corrugated board with his own hands: step by step guide Useful advice,Plot.

Fence for enclosure portion. For its construction, different materials are used. This article will discuss how inexpensive to install a fence of corrugated board.

Content

Product specifications

Decking are waveform steel sheets coated with zinc or a polymer composition. To fit the fence material, the wave height not exceeding 21 mm.

The advantages of using corrugated board are:

- high strength;

- a variety of colors and textures;

- light weight;

- ease of installation works;

- resistance to the adverse effects of environmental factors;

- nonsusceptibility corrosion process;

- long operational period (15-20 years);

- attractive appearance.

Another undoubted advantage is that the cost of corrugated metal fence inexpensively. Moreover, this fence perfectly combines with any material, including stone, brick or metal constructions.

Among the shortcomings should be noted:

- excessive heat in the hot sunny weather (it calls into question the planting near such protections);

- shading portion (of course, if it does not separate the portion on the north side);

- the likelihood of easy removal by thieves (when the owners do not live in a country house).

design designs

The fence from the corrugated floor can be made in two ways: sectional or solid. Depending on the manufacturing method, the need for material will be determined.

Naturally, it is much easier to order installation of a fence from a professional flooring from specialized organizations or individuals involved in this type of activity. But this work can be carried out on your own.

At the initial stage, the project is made. Application on paper:

- accurate location of the fence on the site (taking into account the erected buildings, driveways and the relief of the plot);

- sizes of fence with direct or rotating sites;

- location of support pillars;

- places with significant height differences.

Features of the selection of fence elements

In order to make a cheap installation of the fence from the professional flooring, you should choose the correct materials. For this process, you will need to get:

- professional flooring;

- reference pillars;

- transverse lags;

- fasteners and decorative elements (brackets, plugs, hardware, bar).

Professor

When purchasing the coating, pay attention to:

- the size of the sheet (from different product manufacturers, they may vary);

- wave height;

- material thickness;

- texture and color;

- the absence / availability of grooves for the flow of condensate.

Sheets have high sailboat. This criterion is also taken into account when the frame structure is appropriate.

Three brands of professional flooring distinguish:

- carrying (H);

- wall (s);

- universal (NA).

For the construction of the fence, use the wall material, starting with the brand C8 and ending with the brand C20. Thicatous sheets use unprofitable from an economic point of view. This material is more expensive and heavy.

Support poles

In principle, various materials can be used as reference pillars: metal, stone or wooden timber. But the most practical and cheap option will be the use of metal pipes.

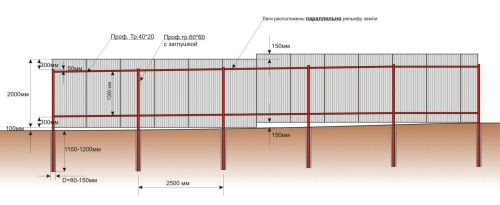

The dimensions of the metal pipes are directly dependent on the likely load. In most cases, the installation of the fence from the corrugated floor is carried out using pipes with a diameter of 6-10 cm (round) or cross section 6 * 4 * 0.2 cm (rectangular).

For the fence from the professional flooring, you can book and finished pipes. And they are suitable for any soil. The advantage of the finished metal pillar is that it has a "heel" (installed directly on the sandy pillow), holes for fixing the sheet and the top plug (protects the inner space space from moisture).

Cross Lags

It is better to use square metal pipes with a size of 4 * 2 * 0.2 cm or 4 * 4 * 0.2 cm.

It is not recommended to use wooden lags. This is due to the fact that the tree will rot in the place of contact with the fastener of the professional flooring. This will lead not only to a decrease in the operational period of the fence, but also to the impossibility of re-use of the material.

When installing a metal fence from the professional flooring also disappears the possibility of using the steel corner as a lag. This is explained by the fact that:

- with lag thickness, less than 2 mm, the fence will not be able to withstand the wind load;

- with a metal thickness, more than 2.5 mm in it will be problematic to screw the screws for the professional leaf.

Fastening and decorative elements

For reliable fixation of the professional flooring, special V-shaped brackets apply. Their mount can occur with the help of various hardware: bolts, screws 2 and 3 cm screws, rivets.

But the best solution is the use of 1.5-3.5 cm tapered screws with neoprene gasket, thanks to which the sheets are tightly pressed against the surface and are not damaged.

If when installing an iron fence from a professional flooring, it is planned to use rivets, then the extreme part of the holes is painted. This is done so that in places of fixation does not appear rust, the inclects of which will be difficult to remove from the corrugated floor. Paint also applies when processing the material cutting places.

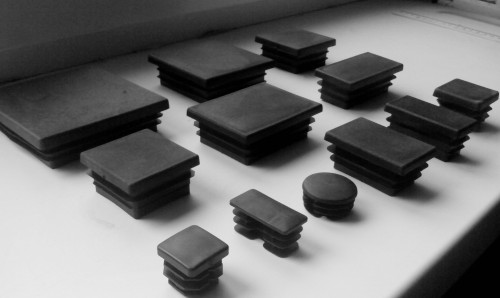

Plastic plugs are closed with metal pipes. In this way, water is prevented inside the support pillars. This problem can be solved with plastic bottles. But they worsen the attractiveness of the fence.

The main purpose of the decorative plank of the P-shaped shape (attached to the sheet) is the protection of people from the cuts, and the material from rust. The extreme part of the slats should be spilled (curved). Otherwise, the installation of slats is fraught with a damage of a metal (scratches) and raising their extreme part over time.

Calculation of materials

Professor

The required number of sheets is determined based on the technology of the fence. With continuous installation, the total length of the fence is divided into a width of a sheet with rounding to the biggest side. In section technology, it all depends on the width of the span. Ideal when one sheet is placed in one span.

When calculating the need is prohibited to compare the total area of \u200b\u200ball sheets with the limit size of the fence. All calculations are conducted by relying on the size of one sheet.

Support poles

The need for bearings also depends on the mounting method of profiled sheet:

- Solid fence. Tubes are placed at a distance of 2-3 m from each other (depending on the sail material). The number of poles is determined by dividing the total length of the fence to move between the pipes.

- Breakout fence. The need for columns depends on the number of sections.

In the calculations should take into account the fact that the mandatory installation is carried out:

- the corners of the fence;

- at the location of the gate and gate.

As for the size of pipes, their length must exceed the length of the fence by 25-35%. The supports are placed in the soil is so deep.

Cross Lags

The need for lags calculated from the height of the fence:

- 2 m - 2 pieces sufficiently;

- over 2 m - 3 pieces.

To determine the total number of cross members should measure the length of the entire enclosure and divide by the length of one lags. Distance from the outermost portion to lag profiled sheet should be in the range of 0.2-0.4 m. The minimum width of the cross member of the support tube is 0.5 wide.

Fastening and decorative elements

The amount of other elements is determined as follows:

- Brackets. 2-3 (lag number) multiplied by the number of poles.

- Self-tapping screws. When two crossbars need screws 6/1 leaf, three - 9 pieces / 1 sheet. Clamps are acquired with a small margin.

- A stub. The number corresponds to the number of supports.

- Trims. fence length divided by the length of the splines, reduced to 4-6% (overlap).

- Dye. weight of 50 cans of enough

Mounting work

Apparatus foundation, pillars and transverse lag

The site where erected inexpensive fence of corrugated thoroughly cleaned. Nothing should interfere with the installation of poles, cross bars and the material itself.

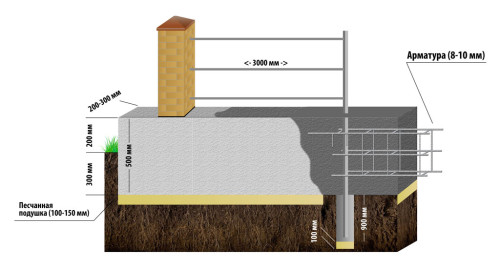

Laying the foundation - a mandatory process when installing fences made of profiled sheet. This is because, in contact with the soil material may be coated with rust and gradually disintegrate.

Construction made of corrugated board, is not too heavy. Therefore, it is a viable option -. Creation melkozaglublennogo strip foundation depth of not more than 50 cm base width depends on the thickness of the metal studs.

Pouring the foundation for the fence is made similarly to its device by any other building. Nuances are in a location of the supporting pillars

- in places with maximum load (corners, the last sheet, gates), the depth of the trench is about 10-15 cm (cushion for sandy device) + 30% of the height of the tubes;

- for other supports - 10-15 cm + 25% of the height of the pillars.

Naturally, at the initial stage of assembling columns is carried out in places where the maximum load. Between the supports necessary to pull the cord by which there is mounting the intermediate pipes.

After determining the location of columns:

- drill is withdrawn via the soil;

- in the pit is filled with gravel and sand;

- processed pipe anticorrosion coating and mounted on the cushion;

- mounted tube;

- it comes pouring concrete.

A month later, when the concrete foundation to fully grasp, held lag installation. They serve as the basis for the corrugated board. For connecting them to the poles used V-shaped brackets. The collected metal lath coated with primer and paint.

Fixing corrugated

We can now proceed to the installation of the fence of the profiled sheet. Laying a first sheet is carried so that it blocked the wave of the next sheet. The process begins at the gate and the gate (you can sometimes encounter a problem, when the last sheet may be cut off).

To provide adequate ventilation, between the trapezoidal sheet and the ground clearance is left in 15-20 cm. Fastening sheets made at the portion that must coincide with the transverse joists.

screws screwed made not to stop, because you can ruin the neoprene gasket. But they should not be spinning and loose. Screws will come off and spoil profiled.

Compound of adjacent sheets occurs by screwing the screws through the top of the wave, and fixing to sleepers - through the bottom. The upper part of the sheet closes the U-shaped bar and tube - plugs.

These days will not be difficult to order inexpensive fence of corrugated. Such a solution is quite practical. And the very fence uniquely embellish a country area on a long period of time.

Videos about installing a fence of corrugated board: