Heat exchanger for the furnace with his own hands Climate

With this domestic instrument, each of us came across at least once in life. For example, one of the varieties of heat exchangers are heated towel rails, radiators and batteries. The main task of the heat exchanger is the heating of water due to the natural circulation under remote tank or heating circuit.

Content

Description of heat exchanger

The construction market sells many electrical heat generators operating from different fuel on the construction market. However, sometimes it is practical to use traditional furnaces. For example, in cases where the house is located in remote rural areas, where problems with the supply of electricity or gas are not excluded. Acceptable placement of the furnace and in the country buildings. But in order for the oven not only could heat the house, but also provided you with hot water, the correct option will be the installation of the heat exchanger.

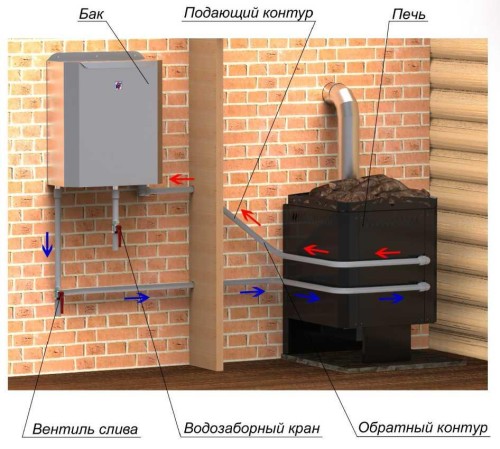

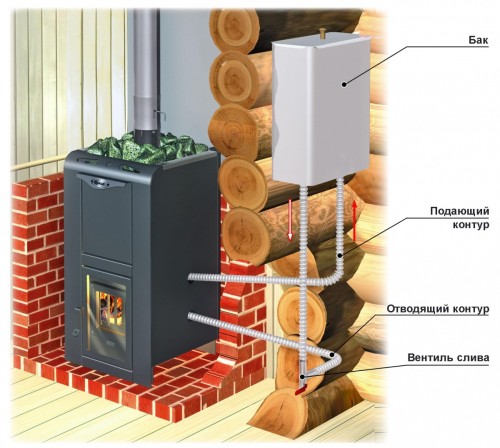

The heat exchanger is a small metal tank, from 3 to 5 liters, with mounted nozzles. The device heats the incoming cold water and sends it to radiators and in a removable tank, with a capacity of up to 100 liters, which additionally joins the heat exchanger. The system of work is provided in such a way that when the furnace is token, the neighboring room is also provided with hot water, and in the case when the bath is not used - water is automatically merged from the system. Directly with the fire, the tank is not in contact, and its installation is made between the furnace furnace and the convector. The furnace is melted in the case when the system is assembled and filled with water.

They differ mainly 2 types of heat exchangers: internal and external:

- The internal heat exchanger is located directly inside the furnace. It is easy to install, however, in the conditions of a brick stove, it is more difficult to get to it. With a metal oven make it easier.

- External - looks like a chimney module and is a pipe hidden inside hermetic capacitance. This pipe takes heat from the furnace. Such a design is easy to repair and carry out maintenance.

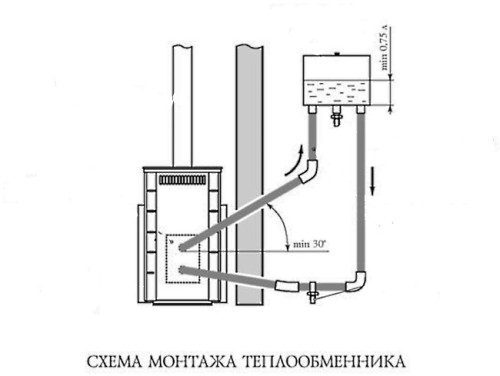

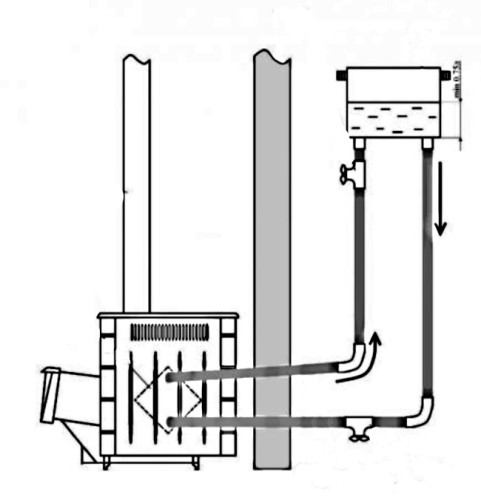

Any kind of heat exchanger for the bath furnace should be filled with water, and in some cases antifreeze. The liquid in them is supplied from the mounted tank. Circulating it in a natural way, the system is performed. Sometimes an electric pump is used for circulation. However, experts recommend using the method of natural water movement in the system, plus it is better if the total length of the pipes will not exceed 3 meters, and the thickness is at least 2.5 cm.

The definition of the heat exchanger area is based on the total area of \u200b\u200bthe room of the bath. As a rule, for heating the standard room, with an area of \u200b\u200b2 sq.m. It consumes approximately 5 kW of electricity. In many respects, this indicator depends on the force of burning fuel in the furnace, from finding the boiler itself, and when the process of the furnace is stopped, the boiler power is rapidly decreasing. The calculation of the surface area of \u200b\u200bthe heat exchanger for the furnace should be done with a margin, to organize a system capable of maintaining the required temperature in the bath.

Principle of operation of the heat exchanger

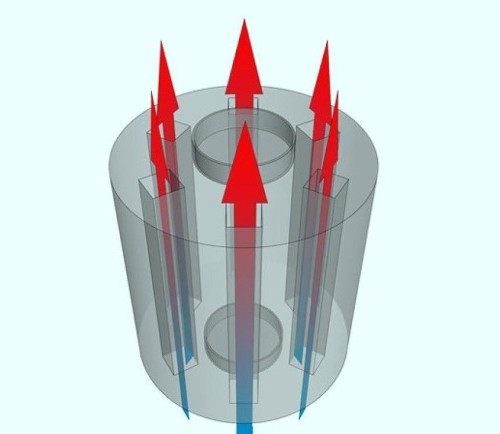

After the extracts of the furnace, the water in the heat exchanger will be heated. As temperature increases, the fluid slowly moves up the pipe. From the lower nozzle, cold water enters the heat exchanger, heats up and moves back to the tank.

It is strictly forbidden to launch the device "dry", otherwise it will lose sealant and will flow. It is necessary to avoid using plastic pipes in the steam room, since it is heated, they allocate toxic evaporation.

A separate type of heat exchanger for the furnace is applicable to the bath as a chimney element. Heat consumption from fuel combustion in such devices is more rational. The main thermal energy, which goes for heating the steam, the heat exchanger, built into the furnace, absorbs the furnace from the furnace. But the self-type device (that is, on the pipe), to heat the water uses the heat of the chimney pipe. As a result, its effectiveness is high.

To understand how the device works, imagine a hot water bottle immersed in cold water. The bottle is cooled, and the water is the opposite, heats up. By the same principle, the heat exchanger works.

Simple words, it is laid in a barrel, a rolled pipe cut with two outputs, which heats up or cools the liquid. A copper annealed pipe is suitable as a pipe. It is simply bent and threading threads are easily attached to it.

The heat exchanger for the furnace can be made according to the principle of water shirt, when the exchange of heat is carried out between the tanks invested in each other. But this type of device does not make a specialist in this matter very difficult.

An old heated towel rail or radiator (perhaps even the car), a serpent, register, collector or metal tank can also be suitable as parts for the heat exchanger. Gas water speakers used are also suitable for this. The choice of materials for the manufacture of the device depends on the duties imposed on it in the future.

The most durable material for the heat exchanger is the food stainless steel. It can withstand high temperatures, while its characteristics remain the same. Zinc, for example, at 200 ° C evaporates, and at a higher temperature, it becomes dangerous for health because of its evaporation. Therefore, heat exchangers with galvanized profiles must be under your supervision.

The design of heat exchangers involves their manufacture of both sheet steel and pipes. The second, in turn, have a large area of \u200b\u200bheating. The heat exchanger from the pipes is most often used in the plates, they are placed under a cooking surface. And in heating furnaces it is advisable to install instruments made of sheet steel, thickness from 3 to 5 mm. Their length is individual and depends on the size of the fuel separation of the furnace.

What is the use of heat exchangers:

- Through the use of the heat exchanger, the hot water tank can be installed away from the furnace.

- The device provides quick heating of the fluid and the entire system.

- The heat exchanger can be applied not only to work in a bath furnace, but also in other heating and heating equipment.

- Easy to mount and dismantle the device.

- Provided that the weld seams of the heat exchanger are durable and sealed, it is able to work for a long time and reliably.

- The heat exchanger forms pairs, heats the water, air in two or three rooms.

- Facial care device.

- High efficiency.

- You can install in any bath.

- Compact dimensions allow you to significantly save space.

- High power of the device and its fast heating.

- Deformation when heated is excluded.

Heat exchanger for a bath furnace with her own hands

The design of homemade heat exchanger for brick stoves is varied. The most acceptable, inexpensive and high-quality option is a stainless steel system.

Below is an elementary heat exchanger diagram for a brick furnace.

Manufacturing technology:

- As the basis of the device, use sheet metal, with a thickness of 2 mm.

- Metal manufacture 2 reservoirs: 1 - upper cylindrical shape, 2 - rectangular. Dimensions are calculated individually, depending on the size of your bathroom.

- Connect the tanks with each other pipes.

- With the help of welding, make the bottom tube and fill the heat exchanger with water. Connect the outlet with the main capacity.

- Fill the system with compressed air and check the seamlessness of the seams.

- Try the length of the pipes if possible to make the minimum. This is necessary in order for large thermal energy streams rapidly transferred to the coolant.

- Before mounting the device into the general system, on the output, and then on the inlet pipe, mounted threads.

- All seams make the most dense, without visible gaps.

- If you do not provide a pump in your device, the water circulation system should be carried out in this way: from the tank, cold water along the pipe approaches the furnace, and the hot water returns to the tank. At the same time, install the tubes with an inclination angle from 2 to 5 degrees.

- To warm the adjacent rooms, heat insulation tank.

- The weak place of the heat exchanger is the susceptibility of corrosion when contacting moisture. Synthetic metal processing facilities will not fit in this case, as they have low thermal conductivity. It is better originally for the manufacture of the system to use more durable pipes from copper or steel.

Operation of heat exchanger

According to the advice of masters, heat exchanger for wood furnace should not be very large, with a power that corresponds to the power of the furnace. The removable tank should be made of medium sizes in order for the time until the furnace occurs, the water in it has time to warm up. In a large tank, the process of heating is stretching for a long time. In a hot brick oven with a heat exchanger, do not pour water or do it with great care. As a threaded seal for connecting pipes with a heat exchanger, use high-quality and heat-resistant materials.

If you do not plan to use the pump in your system, then the pipes should be placed this way: the water from the removable tank should be merged along the pipe into the furnace and the heat exchanger, and from there - in the hot condition to climb the tank. The system will work just as if you place the pipes at an angle.

In the manufacture of heat exchanger for the furnace with their own hands, choose heat-resistant materials, for this high-quality steel is perfect.

Heat exchanger for burzhuyka do it yourself

At home, it is not difficult to make a heat exchanger to the chimney, first need to be in tools:

- 2 sheet metal - 35x35 cm;

- 8 pieces of the pipe (diameter - 3.2 cm, length - 30 cm);

- pipe (length - 30 cm, diameter - 5.7 cm);

- lobzik for metal;

- marker for markers;

- welding machine;

- 20-liter steel bucket.

Manufacturing technology:

- First make the end plugs. From the sheet of metal cut two circles with a radius of 15 cm. Marker Make them marks for pipes. In the center of each round part, it is necessary to place a pipe with a diameter of 5.7 cm. Place 8 elements with a diameter of 3.2 cm in a circle.

- Having made the correct markup, drill holes.

- To accumulate the heat exchanger correctly and easily, you can prepare the plywood pattern with a thickness of 2 cm.

- Sliced \u200b\u200bpipes insert into the holes, qualitatively weld them first to one round metal plane, and then, turning up to another.

- Welding everything correctly, you will have a heat exchanger core.

- A bucket of steel is suitable as a hull. Clean it from the contents of possible plaque and rust. It is better to burn it from the inside and clean the metal brush.

- With the grinding machine, cut the bottom of the bucket, connect the connections (input and output). To do this, use parts of the pipe for chimney that can be purchased in the store.

- In the center of the sidewall design, make a mark for the inlet nozzle and cut the hole with scissors.

- At one end of the pipe, make a notch, and when inserting the pipe in the bucket, start the notches, securing the pipe on the housing. The inlet nozzle is installed.

- Next to the case, place the core prepared earlier, weld it and treat all the seams with a special hermetic and refractory agent.

- When the design is dry after the sealant, paint it and leave drying away for a day.

- The heat exchanger for the oven, made by their own hands, damn the chimney of the bourgear.

- If necessary, you can set the fan near the device so that the warm air circulate indoors.

- The finished device can be both portable and stationary.

Use any heating device will more effectively allow such a air type heat exchanger. With its increased efficiency, it can be saved on fuel and on heating as a whole. As you can see, make the heat exchanger independently does not make up the cost of funds and time in the presence of high-quality materials, tools, and, of course, experience.