Foundation for an extension: Construction Features Construction

In some cases, there is a need to expand the residential area of \u200b\u200bthe house. But it is not always possible to build an additional floor. In this case, the problem solves an extension to the house.

Content

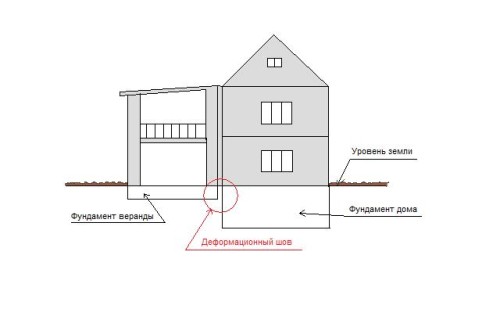

There is a risk of cracking between the main structure and an extension due to uneven shrinkage. The reason is that the foundation for the extension is not associated with the previously built base. About how to prevent errors in construction and prevent the destruction of the house and will be discussed in this article.

Designs of foundations for an extension

The foundation for an extension to the house can be of different designs, which depends on the properties of the soil, on the type of already erected base and other conditions.

Hard connection of the base

For mobile, inclined to the shrinkage of soils, this option is optimal. Especially if it is planned to build several tiers. Distinguish two types of hard connections:

- stove to plate;

- ribbon to ribbon.

The last type is mounted with the next sequence of actions.

- A trench for the foundation is rotated, the depth of which should not be less than the depth of the old base.

- Sand pillow (100-150 mm) is satisfied, which should be sealing. For this sand is pre-moisturized.

- In the old basis from the side of the adjustment of the extension, the holes are drilled with a diameter of 10-12 mm at different angles. The location of the holes is chess, the minimum distance from the upper and lower edge of the tape is 50 mm. The depth of the holes - from ½ to ¾ the width of the main base ribbon.

- Inserting the reinforcement rods corresponding to the diameter of the reinforcement and ride with a hammer until it stops. Outside there are about 400 mm.

- The protruding parts are connected by long segments of reinforcement with welding.

- The crushed stone layer is poured over the sand, the waterproofing material is stacked, a formwork is installed from wooden shields.

- Concrete is poured and the air is driving with a metal rod. After 24 hours, the formwork dismantle. Full secretion of concrete will come 28 days later, after which it is possible to continue construction.

When connecting the "plate to the stove", the armature of the ending of the extension is welded to the mortgage fittings of the foundation of the main building.

Construction of a separate base

This option provides for the construction of a ribbon base with reinforced concrete woodwork. Phased this process is as follows.

- The construction site is placed, there is a trench for a finely blurred belt foundation (about 60 cm). At the same time, it is necessary to lay it above the depth of the old base per shrinkage.

- Several rows of rubberoid are stacked between the base of the main building (or wall) and the formwork for the base of the extension. This is the main feature of the method.

- A sandy pillow is satisfied, formwork is mounted.

- With the help of reinforcement with a diameter of 12 mm, reinforcement is performed.

- Formwork is filled with concrete solution.

As a result, an independent basis is formed. To prevent deformation and reduce the shrinkage, you should be put on the perimeter of the extension of the pipeline pipe. Groundwoods are discharged into a special well.

It is important to correctly calculate the design parameters, for which it is necessary to consider:

- the dimensions of the new structure;

- the total weight of the materials from which the walls are arranged and the roof is arranged;

- loads from finishing materials and insulation.

Stamp Foundation for an extension

The foundation for an extension with your own hands is easiest to build a column type. This method is suitable for easy attacks and saves materials, reduce construction time. It is performed as follows.

- Using the drills, wells are prepared at a distance of no more than 2 m from each other.

- At the bottom of the wells, sand is poured and then compacted. On top lay a layer of large rubble, and then - liquid bitumen (for waterproofing).

- Metal pipes of suitable diameter, processed outside with bitumen mastic, are used as the reference pillars. They are installed in the wells.

- The middle of the pipes insert the reinforcement and pour concrete.

- On top of the support pillars mounted formwork for woodwork. It should be on the same level with the foundation of the previously erected building.

- Armature of the framework (it is laid after the formwork) in several places weld to the mortgage fitting of the foundation of the main building. In the event that it is composed of bricks, it should be made of studs of the desired length of steel rods, with threads at the edges. They are inserted into the drilled holes, after which the wide washers are put on the edges and screw the nuts until the stop. Thus, two bases are tightly attracted to each other.

- The formwork is poured by a concrete mixture.

- After 24 hours, the formwork is dismantled, after harvesting concrete, construction continues.

During the drying, concrete is recommended to close with a polyethylene film or periodically moisturize it: this will allow the solution to dry evenly and prevents its cracking.

Which one of the described methods is more appropriate to solve you.

We also recommend the video on how to fill the foundation for an extension and prevent errors that can negatively affect the reliability of the entire structure.