Masonry grid. Characteristic and application Building materials

The masonry grid is manufactured by welding the segments of the wire with a diameter of 3-5 mm, located perpendicular to each other. It is a structural material necessary to harden the brick masonry and concrete products.

Content

In addition, the masonry grid is applied at:

- construction fence;

- constructions of cells;

- separation of building bulk materials;

- strengthen arctic structures;

- stacking ceramic tiles.

There are several types of masonry grids that differ in the method of manufacturing and destination.

Masonry mesh for aerated concrete

To reduce the effect of tensile loads in the structures of buildings and structures from aerated concrete blocks, it is necessary to use a masonry grid when the walls are erected. The mechanical strength of the aerated concrete is not enough and there is a possibility of cracking in the absence of a grid. At the same time, it is necessary to take into account the type of masonry and the size of the blocks.

The conditions for applying the masonry grid are as follows.

- When erecting a wall of 625 × 400 × 250 mm of the 1st category, which has the strength of B3.5, reinforcement is optional.

- In case of construction of two to 200 mm blocks, a masonry reinforcement grid is necessary. It is placed every 4 rows in glue or solution.

- The grid is used if the wall is built from large-format blocks with simultaneous cladding brick.

- Be sure to reinforce the masonry on the solution from the blocks of the 3rd category with strength B2.0. The grid in this case is placed every three rows.

- The laying of the first floor of multi-storey buildings is reinforced.

The following types of mesh are distinguished for aerated concrete blocks:

- steel masonry mesh, the sizes of cells of which 50 × 50 (wire diameter 3 and 4 mm);

- mesh masonry fiberglass and composite: for its manufacture, basaltoplastic and fiberglass rods are used, laid perpendicular to each other and connected by wire clamps (adhesive can also be used).

Polymer masonry mesh

Basalt grid masonry or propylene is used to reinforce the masonry. Raw materials for its manufacture serves continuous basalt fiber. With it, it is installed a reliable connection between the rows of blocks. The grid delays the solution without giving fill the voids, which is important for thermal insulation. Also, the reinforcing grid is used when:

- floor screed device;

- applying a thick layer of plaster;

- reinforcement of inter-storey floors;

- road coat reinforcement.

The polymer masonry grid has a number of advantages that distinguish it from similar materials.

- The polymers are resistant to the effects of an alkaline medium of cement mortar and are not subject to corrosion, due to which the service life of such a grid will be longer.

- From destruction under the influence of solar radiation, the polymer mesh is prevented by elements of a building structure.

- The polymer mesh is easier to adjust to the place of installation: it can be cut to metal scissors without applying special efforts.

- Its cost is lower than that of metal grids.

- With its help, the masonry becomes more durable, which allows you to save the solution.

- It has a smaller weight than a metal mesh.

- It is a good heat insulator, does not carry out electricity.

- Elastic, withstands significant loads during bending.

- It is well combined with foam and gas-silicate blocks, brick, stone, cellular concrete blocks.

Important: due to its smaller mechanical strength, the polymer mesh is used exclusively when erecting low-loaded partitions. In the bearing walls, a steel wire mesh should be laid.

The best values \u200b\u200bof strength differs a grid with cells of 25 × 25 mm. In order to provide better adhesion, use the impregnation with a polymer (acrylate).

Weight masonry grid

The masonry grid is made from various materials, it happens from different thickness of the rods. The difference can be in the cell parameters, in the presence or absence of a coating. All these factors affect its weight. You can calculate it using a special LotServiscalc 3.3 program (weight calculator), but there is a manual calculation technique. To do this, make the following actions.

- We know that the mass is equal to the product and density, that is,: m \u003d v × p. The volume of the wire is calculated as V \u003d S × L, where S is its cross section, L is the length.

- It is noted that the total length of the wire depends on the size of the cell and the grid area. From here, it is possible to calculate, for example, for the manufacture of 1 m² of the grid with a cell of 10 × 10 cm it is necessary to put 11 segments of 1 m in one direction and the same in the other. Total wire will be required 22 m.

- The cross section is calculated by the formula: S \u003d π d² / 4.

- To determine the mass of the grid, we use the expression: m \u003d π d² l ρ / 4000, where L is the length of the wire, ρ is the density of the material (reference data).

The mesh is most often made from the wire of the circular section, but oval, rectangular rolled and segment can also be used. Then the calculation of the mass is performed similarly, but formulas are used to calculate the cross section of the oval, rectangle and the segment, respectively.

We indicate, for example, some parameters and sizes of masonry mesh cells:

- 3ВР1, weight 1 m² - 2.21 kg, cell size - 50 × 50 mm;

- 3ВР1, weight 1 m² - 0.99 kg, cell size - 100 × 100 mm;

- 3ВР1, weight 1 m² - 0.72 kg, cell size - 150 × 150 mm;

- 4ВР1, weight 1 m² - 3.62 kg, cell size - 50 × 50 mm;

- 4ВР1, weight 1 m² - 2.02 kg, cell size -100 × 100 mm;

- 4ВР1, weight 1 m² - 1.24 kg, cell size -150 × 150 mm.

Galvanized masonry mesh

The zinc layer on the surface of the steel wire serves as protection against corrosion. Galvanized grid is used in construction:

- as a masonry grid for bricks;

- when applying plaster;

- to strengthen the screed;

- when pouring inter-storey floors;

- when erecting foundations.

The grid production technology is as follows.

- The wire is cut equal to the length of the segments and stacked on a special table. The upper row is perpendicular to the bottom.

- In places of contact of the rod using automatic welding, their connection is performed.

- The protective layer of zinc is applied by electroplating: rolls or cards are immersed in a special drum, in which electrolysis occurs. As a result, steel bars are covered with a thin layer (8-9 microns) zinc.

For better clutch with a solution on the rod rods, notches are applied.

Your attention - video about the operation of automatic lines of production of the welded grid.

The zinc coating grid has the following characteristics:

- its strength increases as the size of the cells decreases (withstands large loads);

- strength directly proportionally depends on its weight: the higher it is, the more significant the load of the grid can withstand.

Plastic masonry mesh

Raw materials for the manufacture of plastic masonry grid is propylene. This material provides a grid near distinctive qualities, namely:

- resistance to alkaline medium of concrete solutions, thereby increasing its service life;

- easy during installation: it is easier to cut, than metallic;

- it is economically profitable: when it is used, dear glue is saved (it requires a smaller amount for the construction of walls).

What size is a masonry mesh

The masonry grid refers to the weld according to the classification by manufacturing technology. The main technical requirements for it are contained in GOST 23279-85, according to which the wires of BP-I and B-і should be used for production (classes according to GOST 6727).

To make sure this is a high-quality masonry mesh, buy material suitable for construction, you need to weigh the entire roll and determine the specific weight of 1 m². The difference with reference values \u200b\u200bshould not exceed 5%. Otherwise, we can conclude that a thinner wire or cell size has been used for production, do not meet the requirements of regulatory documents.

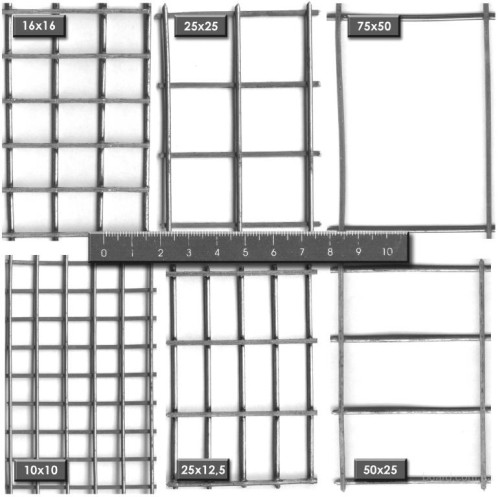

The dimensions of the cells of standardized masonry grids - 50 × 100, 100 × 100 and 50 × 50 mm. Meshs can be made with large and smaller cells. A masonry mesh in maps or rolls is supplied, the width of which is up to 2 m, length - up to 6 m. Wire diameter - 3-6 mm.

Masonry grid: Price

The price is formed by the manufacturer depending on the length and width of the map, the sizes of the cell, the cross section of the wire used for the production of the grid and the presence of the coating. In Moscow and the Moscow region:

- galvanized grid is implemented in the range of 200-347 rubles / m²;

- welded (in maps), from wire cross section 4 mm² with cells 50 × 50 mm - from 101 rubles / m²;

- mesh BP-1 for roads 50x50x5 mm - from 161 rubles / m²;

- plastering and masonry mesh of plastic (with cells 13 × 15 mm) - from 16 rubles / m².

In conclusion - video demonstrating the advantage of basalt masonry grid.