Liquid thermal insulation, material features Building materials

From the longstorm time, a person tried to make his dwelling as warm and cozy. At first, natural materials were used - straw, animal skins, moss, clay. But with the development of humanity, construction technologies were progressed. More effective and reliable materials came to replace primitive insulation - foam, mineral wool, polystyrene foam. Liquid thermal insulation gradually moves to the background all modern insulation, being a completely new and material that takes construction to the next step of "evolution."

Content

Specifications

Liquid thermal insulation or heat-insulating is an innovative composition designed to form an energy protection barrier on various surfaces. Initially, liquid thermal insulation was developed for processing steam pipes, air ducts and plumbing, but in the future it showed itself well as a heat transferser in refrigerators, tanks and tanks. The heatcharaska was actively used in the space industry, and today is widely used in construction.

Operating principle

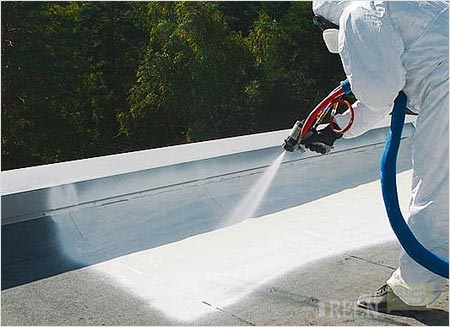

The unique properties of liquid thermal insulation or power grumbling heat-insulating can maintain a significant amount of energy with a coating thickness of only 1 mm. You can apply heatflake with rollers, sprayers or brushes. After drying on the surface, an elastic matt film is formed, which has specific thermophysical characteristics. The coating operates according to the principle of "heat mirror", reflecting the heat that falls on it and forming a steady temperature barrier.

The material studies revealed that the heat insulating paint can reflect the heat only with direct infrared radiation and high temperature. Therefore, it is impossible to apply it in closed rooms where there is no direct thermal impact. Liquid thermal insulation perfectly "works" on the roof or hot tubes, reflecting the heat from the roof-chopped from the sun or not giving cooling the pipes of hot water supply.

Composition

Liquid ceramic thermal insulation consists of high-tech synthetic materials:

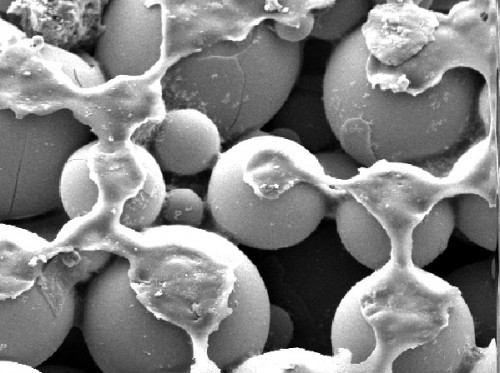

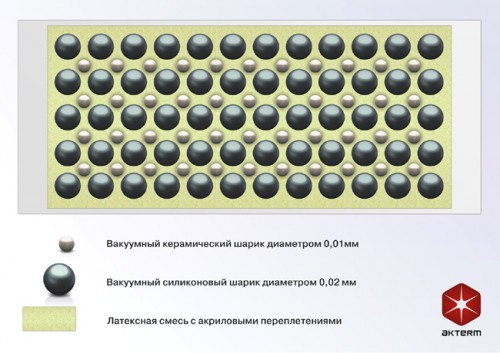

- filler - empty microspheres made of ceramics, glass or polymer balls filled with air. Fillers may have a different composition, the level of homogeneity and dimensions of fractions, as well as various ratios of components;

- binder substance - polymers (latex or acrylic).

Depending on the scope of application, various additives affecting certain properties of the coating may be part of the liquid heat insulation.

Types and manufacturers of liquid insulation

Today, the popularity of liquid thermal insulation is gaining momentum. In the domestic market, it appeared relatively recently, but has already managed to establish itself as an effective means for saving heat. We will look at the most popular brands representing ultra-thin heatcharak.

Heattette

Teplokraska in the form of a suspension that does not require breeding and fully ready for work. It is permissible to use at temperatures from -60c to + 250c.

A layer of heat-glass heat metal with a thickness of 1 mm is able to replace 2.5 cm of polystyrene or 5 cm mineral wool best quality.

Liquid thermal insulation of this brand is suitable for insulation of pipelines and walls in residential buildings.

The main advantages and characteristics of heat-glass thermometers:

- the room temperature rises by 4-6C in the cold time;

- significantly reduced the cost of heating or air conditioning;

- prevents the formation of condensate or mold on the treated surfaces;

- coverage service life of more than 15 years;

- high aesthetic coating;

- no load on the walls;

- saving space inside the wall (a pair of millimeters of heat-glass replaces several centimeters of any other insulation);

- the service life of processed pipes and containers increases.

Actor

Reviews of Liquid Isolation Mark Actor allow you to say that this is one of the best and in demand insulating materials in the modern market. Teplokraska Actor is manufactured using innovative technologies and high-quality foreign raw materials. It is distinguished by excellent anti-corrosion properties and is able to withstand heating to + 600C.

Characteristics and advantages of liquid thermal insulation of brand actor:

- the heat-glass layer in 1 mm is able to replace 5 cm mineral plates;

- high anti-corrosion properties;

- opposes the appearance of fungi and mold, and also destroys the already developed fungne;

- high reflective properties - up to 95% of radiation in summer, up to 70% of heat in winter;

- the possibility of processing hard-to-reach areas;

- service life of 15 years;

- the possibility of tinting and applications as the finishing of the facades;

- the possibility of using at any time of the year (in winter work is permissible at temperatures to -25c);

- excellent grip with all surfaces with the exception of polyethylene.

Corundum

High functional liquid ceramic thermal insulation, which interacts with any surface. Unique properties are caused by the composition - 80% of ceramic microscopic spheres filled with discharged air. Since the thermal conductivity of the air is extremely low, heatcharaska guarantees the minimum heat loss.

Characteristics of the heat-glass brand Corundum:

- high level of thermal insulation;

- good adhesion with any type of surface;

- it is permissible to use as a basic coating for use in various fields (heat transfer, enclosing structures, chimneys, steam boilers, internal and external surfaces, etc.);

- temperature barrier from -60C to + 200C;

- service life for more than 15 years.

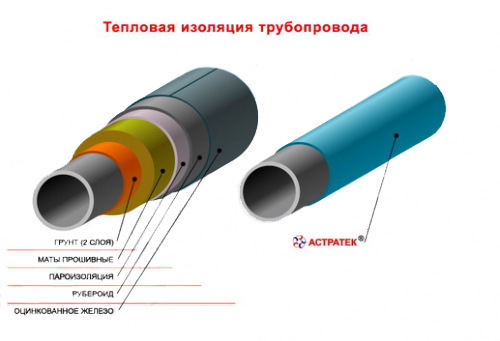

Astrathek

Liquid thermal insulation of the Astrathek brand is leading in the construction market. Its popularity is explained by the presence of a conclusion in the thermal properties obtained after testing on the acting heating industry. The conclusion is provided by the Astrakhan Institute of Metrology, Implementation and Certification.

The Astarate heat-insulation is an innovative thermal insulation on a water basis, which includes ceramic microspheres and acrylic polymer binders.

Ultra-thin thermal insulation is used both in the energy industry and in construction. It is treated with facades, roofs, slopes, concrete floors, inner walls and pipelines, in general, everything that requires protection against heat loss or condensate formation.

Characteristics of the Astrathek Heatlook:

- universality of use (suitable for all surfaces);

- prevents condensate, mold or fungus;

- large temperature range of l -600s to + 2500 ° C;

- environmentally friendly material;

- the composition eliminates the presence of volatile organic;

- fireproof (at the maximum allowable temperature, charring occurs, and in the case of the threshold, the decomposition of nitrogen and carbon oxides).

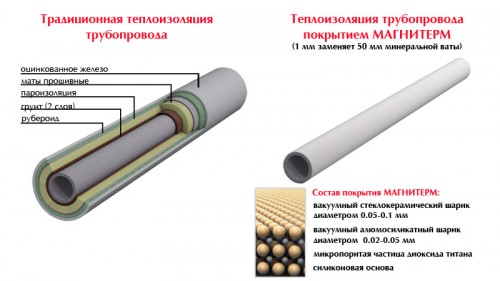

Magtert

The ultra-thin energy-saving heat-seller, the main task of which consists in rapid and economical elimination of heat loss, the occurrence of mold or fungus. As part of thermal insulation, there are several types of microspheres filled with vacuum, binder silicone substances, as well as special additives that prevent the emergence and development of corrosion.

Characteristics of the heat-glass "Magtell":

- preventing the formation of mold, fungus or rust;

- temperature range from -60c to + 600C;

- permissible application at temperatures from -30c to + 150c;

- reducing room heating costs by more than 40%;

- efficiency (3 mM thermocrash replaces 16 mm minvati);

- elementary use.

Isollat

The liquid thermal insulation of the brand "Isollalat" is recommended for the processing of the internal and external surfaces of the prefabricated metal structures - warehouses, hangars or garages.

In the case of bilateral surface treatment of the heat-insulating "isollates", it is possible to achieve a maximum effect to save heat and heat protection in the summer.

In the "Isolla" there is a special inhibitor substance, therefore the heatcharaska is suitable for protecting galvanized surfaces. The inhibitor prevents the spread of corrosion and destroys it in the earliest stages.

Characteristics of Heat Color Brand "Isollalat":

- designed for processing metal coatings;

- high degree of rust protection;

- before applying the surface needs degreasing or covering any suitable primer;

- weak adhesion with aluminum surfaces and some types of stainless steel.