How to concrete sex garage Floors,Construction

The floor in the garage should be distinguished by strength characteristics and practicality, because in addition to storing the car to the room there is an additional load of the pantry and workshop. Various oils can drip out of the car, gasoline, therefore high demands for moisture resistance and chemical inertness are also placed to the coating. The simplest option that is distinguished by reliability is the device of concrete floor in the garage, which is quite feasible.

To do this, you will need to perform such a front of work:

- foundation of the base;

- waterproofing selected material;

- insulation with polystyrene foam plates;

- laying a metal frame;

- pouring concrete mix.

Content

Layered floor design

To begin with, it is worth noting that the floor design will consist of separate layers. As the basis, you can take:

- gravel and sand, then the pillow it should cover the entire surface with a layer of at least 15 cm. The bottom fall asleep with sand with a thickness of about 7cm, the gravel is laid on top;

- sand and crushed stone, it is important to compact the foundation well, remove emptiness.

To obtain a smooth coating without failures it will take good leveling of materials. Seal the pillow with water, when watering the sand instantly smoking, gravel is easier to rub the log.

Properly thought out waterproofing - the key to long-term operation of the floor in the garage

The concrete floor in the garage needs waterproofing, it may be necessary to embody it:

- ruberoid;

- hydrokhotloxole;

- polyethylene.

Isolation, the edges of the selected material must be divided into the prepared pillow. When choosing a polyethylene film, it is important to take a dense material and spread into two layers, one may not have sufficient strength. All bands are laid by the mustache, brush together with a polyvinyl chloride ribbon. Hydrosteclozol is necessary to ensure heat resistance and frost resistance of the coating, it refers to bitumen materials with fiberglass cloth. The last material provides increased waterproofing, and the use of the sprinkling limits the process of rotting and forming the fungus in structures.

Concrete floor insulation in the garage

It is worth taking care of the insulation, but only in the case of heated premises. Because the insulation of concrete floor in the garage will be useless measure in the absence of a well-thought-out heating system. Many perform the heat insulation of the coating in advance due to the further insulation of the entire design. As a material for the insulation layer, polystyrene foam plates are taken, their thickness should be 7-10 cm. Mostly use PSB-C-35, it is used specifically for the arrangement of the floors, such a density is ideal for garages. Sheets, if necessary, cut, but in any case, the polystyrene foam must be covered with a film.

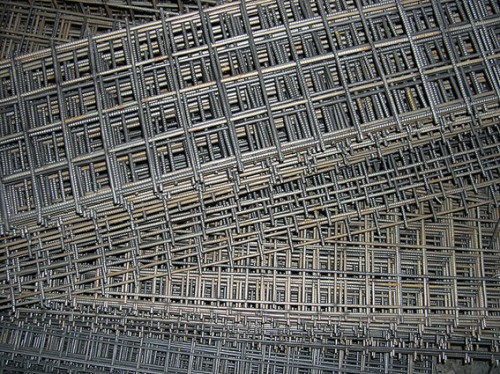

Reinforced Mesh - Important Part of Design

To make a concrete floor in the garage, a metal frame is required. For him use:

- finished welded stack;

- wire;

- wooden rails.

The reinforcing grid must have the sizes of the cells 100x100m, and the diameter of the rod 5mm. From the wire binding of the rods can independently make the grid, but the finished option is much more convenient to work. The frame is laid on the entire surface of the floor, only take into account the heat gap - the distance from the walls is taken 30-40mm. This indent will allow to limit the destruction of concrete when temperatures drops. So subsequently, the repair of concrete floor in the garage at the first cold. Also installed wooden rails with a height of 10 cm in the frame. They are necessary for pouring the solution by strips, so their periodicity in 1M will be the best solution.

Calculation of necessary materials

It remains to concrete the floor in the garage, first calculate the required volume of the solution. The result is obtained by simple calculation length, width and thickness of the future base. The value is multiplied with each other and recognize the required volume of concrete. For the fill, it is recommended to use concrete M-300, put it on the height of wooden plates. For cooking, you need components of cement, sand and water in a ratio of 1: 3. The proportions 1: 4 and 1: 5 are often used depending on the existing cement. The new developments of dry construction mixtures of the sandbetone M-150 allow you to obtain a high-quality base with an ideally smooth surface. Thanks to the supplied plasticizer, a certain effect is achieved. In this way, the concrete floor alignment is carried out in the garage.

Pouring concrete solution

For the process it is necessary to carry out:

- markup;

- directly bay of the mixture;

- alignment.

Pre-conduct the markup of the working area with the help of lighthouses. They can be wooden bars, fittings, tubes or simply lanes of concrete. For a rectangular room, you must install one lighthouse in the middle, and the rest go around the perimeter of the walls. All work is carried out in terms of the level, the thickness of the concrete floor in the garage is determined. Pouring occurs by the prepared solution to fill the entire surface. Considering that the mixture is quickly grasped, it is worth working at a certain pace. With independent work, buckets and shovels use, the perfect option is considered the placed mixer directly on the place of the fill. Typically, it does not arise difficulties, if you know how to concrete floor correctly. It is easier to carry out all the work by the company of several people, so alone can be responsible for the preparation of the mixture, while others for sealing and alignment. A certain pace of work and the coherence of the process is produced.

Nuances of the fill in the garage

Concrete floor device is performed in accordance with an important condition - slope. It is taken at the rate of 1.5-2Cm / m, which is 1.5-2%. Blind is taken towards the goal or waste grille.

The fill of the concrete floor in the garage should be carried out in one day, then a solid monolith is obtained with an optimal indicator of strength without drops and cracks. The solution is uniformly distributed and tamped by the rule or prepared rack. After the fill requires moisturizing every 10 hours, water will limit the appearance of cracks afterwards. To froze the concrete floor, it usually grabs 6-7 days. If the finish alignment of the concrete floor in the garage consists of a special mixture, you need to look at the packaging of the material used. A ready-made robust surface is obtained, but sometimes the owners wish as a final stage to cover concrete epoxy or polyurethane compositions. The main thing is to know that the surface should remain rough for a good clutch with the wheels of the car.