Sat drives for chimney - characteristics and features of installation Building materials

Chimney is an integral part of the design of the heating system. From high-quality chimney, not only the return of heat, a fireplace or a boiler operating from gas, but also fire safety, as well as the planned service of the entire heating system installed in the house. Another important moment - when the chimney is installed and works properly, condensate will not accumulate in the walls on the walls.

Content

Even before, in the withdrawal of flue gases, materials from stainless galvanized steel began to apply, in each house there was a traditional chimney from red refractory bricks. For many years, this durable material served not only for the construction of a chimney furnace, but also for laying a fireplace or stoves. Now name the brick is the only durable material for the output of exhaust gases, it is impossible. In addition, brick chimneys have shortcomings, unlike the sandwich tube.

Stenched Stenched Pipes – this is a universal approach for any installation of the heating of the room, which uses both liquid, so solid or gaseous fuel. The exception is only electrocotels, which during operation do not produce combustion products.

Design of chimney

The name of the chimney pipe Senvich says that it is multi-layered. Its layers are going on the principle of the well-known sandster. The design has two pipes of different dimeter. Inside the pipe is another metal sheath, which has a construction term - raincoat. This part is made exclusively from high-quality steel, which will not rust. In the space between the two pipes there is an insulating material.

Stainless steel for sandpipes is the only material that can resist the exiting combustion products, in particular acids: coal, sulfur and sulfur.

Exterior pipes are made of less durable material:

- copper;

- brass;

- enamel metal;

- galvanized metal.

A freight pipes are often found on sale, in which the inner and outer tubes are made of one material - stainless steel.

In order to fill the space between the two pipes, a special insulation material is used - mineral wool. It has good heat resistance and has low thermal conductivity. The thickness of the insulation depends on where the pipe will be operated: indoors or outside. Minvati thickness can range from 25 to 80 millimeters.

Assembly rules

The main requirement for pipe compound is their tightness. Senwich-pipes for chimney can be a different connection:

- Flange.

- The principle of "bridge".

- Bayonet.

Standard yield for chimney has a round shape, with a different cross section of the inner diameter. The size is selected individually, depending on the installed heating unit. For example, for a gas boiler having a power up to 40 kW, the diameter is 130- 200 millimeters. For heating furnaces, as well as fireplaces, a larger section is needed - 200 - 280 millimeters.

On this photo, you can visually see how the sandwich tube is going to the chimney.

The sensational chimney consists of separate elements - sections. The length of one section is from 25 mm to one meter. At each end of the element there is a searched, equal to the thickness of the wall. This is necessary in order for the design of the chimney going easily, and was reliable.

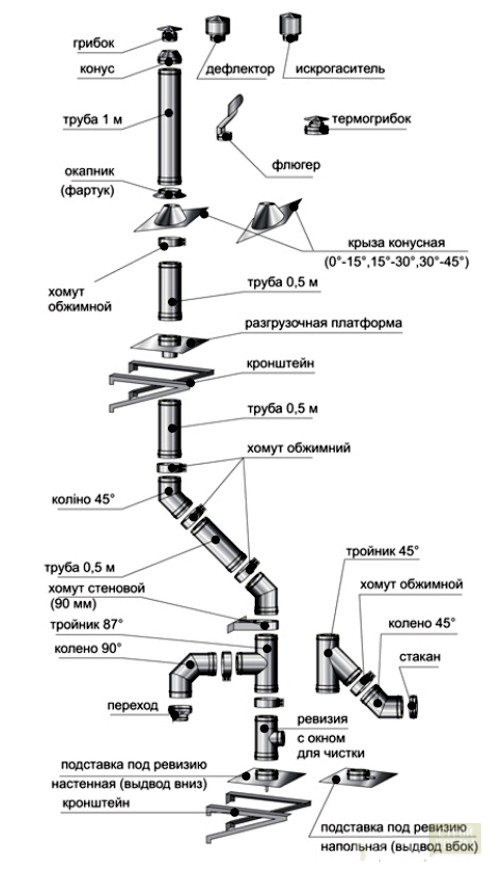

In addition, manufacturers are offered to acquire sandwich pipes for chimney in the kit, which includes:

- turn;

- deflector;

- tee;

- cap;

- revision;

- overlapping and roofs.

About properties

Strength

Internal material: steel. It is necessary to approach the choice of material, because the service life of the chimney directly depends on it. It is advisable to purchase models having a shell with a thickness of at least 0.8 millimeters, steel brand - AISI-309 or AISI-310. Such pipes will be operated about 20 or more.

If the product is acquired from another steel grade, with a wall thickness of 0.5 millimeters, such a pipe will serve no more than ten years.

Heat resistance

The better the steel, the higher the heat resistance. With a fairly frequent phenomenon, like the fire of soot in the chimney, when the temperature is more than a thousand degrees, the steel of the brand 309 and 310 will not be brewed. Of the cheaper material, such a temperature can lead to depressurization of the chimney design.

You can see the sections of sandwich pipes, made from low-quality steel grade 430. Such steel is considered less heat-resistant, it can withstand the temperature of more than 900 degrees only once. Such a pipe is not suitable for heating systems operating on solid fuel. It can be installed for gas boilers, which have a low temperature of the output of combustion products.

Insulation

This moment when choosing pipes for the chimney is impossible. The inner space between the pipes is filled with basalt fiber (mineral wool). Insulation can be made of different material. If there is a material from an organic resin in the layer, then thermal insulation will only work at a temperature plus 450 degrees. If such a binder is not present, then the insulation will withstand higher temperatures - plus 700 degrees.

Mounting. Features of work

Saintwich pipes are easy to mount. Special differences in installation between chimneys for gas boilers, baths, fireplaces or furnaces.

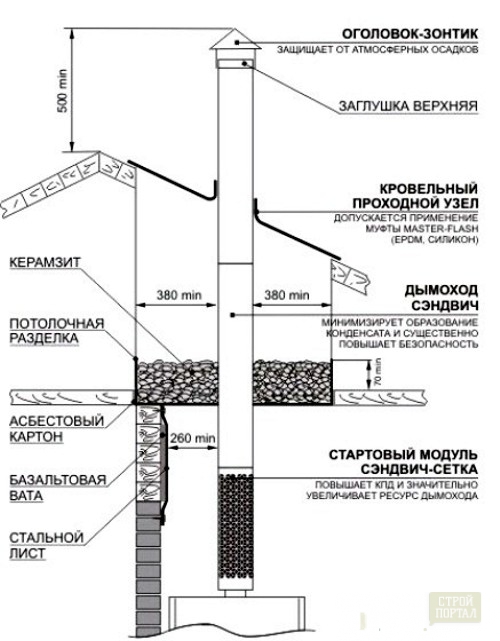

Chimney mounting scheme:

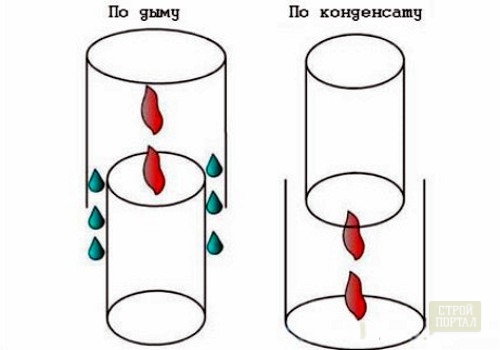

A distinctive feature of the installation of sandwich pipes is that they are mounted below. Immediately over a boiler or other heating device, an ordinary pipe is installed, which serves as an adapter. Due to this pipe, the heat transfer will be increased and the life of the chimney itself has been extended. In order to avoid burns, the pipe must be protected by a protective screen. Further, the pipe is connected to the most instrument of heating, the connection "according to the smoke" - this method means the following: the pipe must be put on the nozzle so that the gases do not come out into the room. How it is done, you can see in this picture:

Next, the single pipe is inserted into the first sandy tube also "by smoke". But one end of the pipe is the top, it is designed so that all subsequent pipes that will be expeded at the top are inserted already "on condensate". This will protect the layer of insulation from moisture that flows inside through the walls of the chimney.

In order to increase the tightness of the compounds, the joints are treated with a special sealant, which has a high temperature resistance, and then pressed the clamps. In addition, all the design of the chimney has been stable, every two meters the pipe attach to the wall with special connecting clamps.

So that the channel is conveniently cleaned, the so-called "revision" is installed - this is a special compartment with the opening door or a "glass" that opens the lid.

In a place where the chimney pipe passes through wooden structures, the external thermal insulation is additionally stacked for these places. Insulation material - Mineral wool must have a thickness of at least 100 millimeters.

To eliminate the drop in thrust and efficiency of the heating installation, there should be many turns and horizontal sections in the chimney, in which the length is greater than one meter. Maximum turns are allowed - three.

Sat drives for chimney have different prices. It depends on the diameter of the pipe, the length of the sections, the steel grade, as well as the quality of the surface of the pipe (matte or polished). For example, the minimum price of a pipe, a length of one meter, the material - stainless steel begins from 1300-1400 rubles. If the parameters of the pipe are the same, and the outer shell is made of stainless steel, then the cost of such a pipe will be from 1,700 rubles and higher.

When choosing sandwich pipes for chimney, it is necessary to ask the seller about the steel brand, since it is not in all the prices there is this item.

Installation of the sandwich chimney can be viewed on this video: