Characteristics and diagram of turning machine Instruments

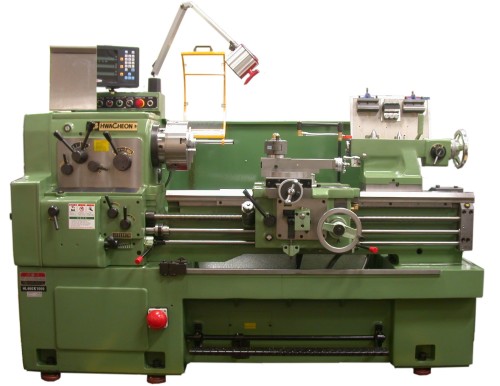

The processing of metal, wooden and plastic blanks by cutting and sharpening cannot be made without special equipment - a turning and screwing machine. Its capabilities include performing any types of mechanical processing of materials, scratching surfaces, carvings and drilling holes.

Content

Machine description

Metalworking machines are one of the key components of the technological process in any industrial production. As follows from statistics, more than 50% of all parts manufactured are pre-calculated on the lathe. A turning machine - equipment intended for complete processing of blanks, the price of one unit on the mechanical equipment market varies from 30 thousand and to 9 million rubles. It all depends on their dimensions, technical characteristics and functionality. Among the latter: the lathes of black and non-ferrous metals, the messenger of the cones, cutting the metric, modular, inch thread.

Depending on the purpose of the machine, there are also universal and specialized. The name speaks for itself, universal equipment is able to carry out a wide variety of operations: inner and outer treatment of both end, cylindrical and conical surfaces, grinding, cropping, deploying holes. Devices of this type can be with a horizontal and vertical location of the spindle.

Specialized installations are designed to perform more specific tasks: sharpening smooth and stepped shafts, rolling rolls, pipes, couplings and so on.

In the household and industry, turning and rope machines are operated for a long time. Domestic industrial enterprises make this equipment of a variety of modifications: desktop and stationary heavy, to work with blanks with a length of 12.5 cm to 2.4 m, and with the maximum diameter of the treated surfaces from 8.5 cm to 0.5 m.

The main workshop of the machine is the spindle, which rotates with the workpiece, while across and parallel to the axis of the workpiece rotates the cutting tool. The machine performance directly depends on the power of the spindle. What it is higher, the better the machine removes the chip metal with the details and processes more massive parts.

According to the accuracy of the manufacture, they are divided into: Machines of normal and high accuracy, (H) and (P); high-precision (B); particularly high (a); Particularly accurate (C).

The technical characteristics of turning and rigging machines are the main indicator of the readiness of the device to work. Turning equipment must have the following characteristics:

- the maximum diameter of the workpiece that is processed;

- maximum distance between the centers of the RMC;

- maximum length of the processed part;

- the number of spindle speed is one minute.

Turning and screwing devices are usually applied in the work of small production, for the manufacture of single parts. If necessary, the machine is equipped with additional devices that allow you to expand the range of its capabilities to a mass scale.

Constructive features:

- rear assembly machine with a turn of 5 mm;

- the bed is made of gray cast iron;

- the material of hardened and ground gear wheels - chromonicel steel, the upper slurry can rotate 60 degrees;

- the guide nodes of the machines have sanded surfaces and induction hardening;

- on the spindle three adjustable conical roller bearings.

Basic working knots

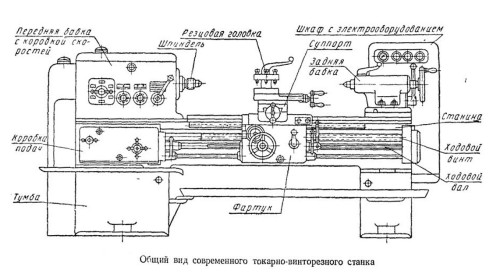

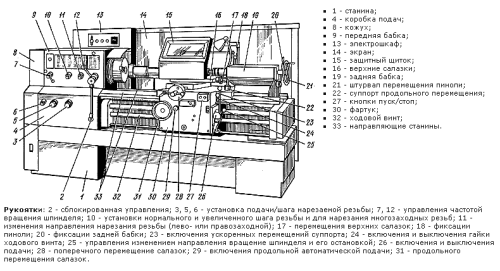

The main nodes of the turning and rignet cutting machine below the figure below are highlighted by text in the detailed description:

- All major nodes of the machine are mounted on the bed.

- Front node (grandmother) is a starting device for rotating the workpiece processed. In its case there is a speed box.

- Rear knot (grandma) When processing holes, holds the drill, cinker and scan.

- Chassis and running screw launches in operation box. She also changes the number of their revolutions.

- The transducer of rotational movements of the undercarriage and screw into the straight movement of the caliper is a apron.

- The caliper, in turn, moves the cutter on the cutting head.

The main difference between turning and turning and tube machines consists in the presence or absence of one part - the running screw. In the latter, this item is present, so that the device can cut the thread cutter.

The schematic diagram of the turning and screwing machine with the designation of all the main nodes and fasteners is shown below in the figure.

Principle of operation of the turning and screw machine

The internal device of the turning and rigine machine is a system of individual rotating and precisely fitted elements fixed on the working bed. The principle of action of these elements is as follows:

the part of the spindle in the horizontal position is indulge in the rotation, the movable sharpened cutter removes the layer of unnecessary material from it. The functionality of the machine will expand if it is used on it additional equipment for milling, grinding, drilling of radial holes.

Turning and screwing machine RAM

Equipment of the latest modification - the turning and screwing machine RAM is very popular with industrialists. Another name of the machine is the axis, he successfully combined the qualities of ordinary turning devices with an axis type Pinol. The elementary and simple technology of the machine is clear to a person who is not knowledgeable in the field of metalworking. When docking the equipment with the part that needs to be processed, it begins to slightly slide along the surface of the workpiece, thus performing its cropping. This process is fast, light and high-quality.

CNC Turning Machine

A decent replacement to the old worn equipment is a turning and rope CNC machine. It is easy to install and simply exploit, in addition, it meets the latest requirements of the modern industry.

The performance of such machines is much higher than the remaining existing models of the corresponding class. By the way, any enterprise that acquires such equipment on its production, in one account solves existing problems with low productivity. The CNC machine can be used in a single manufacturer of parts, as well as on production using labor-intensive technologies. Among the advantages of this unit, you can allocate reliability in the work and high accuracy of processing billets.

Safety when working on a turning and screw machine

Before you begin to work, the turner must perform the following actions:

- so that the clothes do not hit the machine's running elements, it must be fed. Long hair should be covered with a golk, cuffs are exposed. With bandaged limbs is also forbidden to approach the working unit;

- perform ground grounding;

- in order not to cool down in the process of work at the machine, the lattice under legs should be fixed and stable;

- the running screws and rollers need to be lubricated. The oil level also needs to be checked in the velocity box and in the oil tank;

- the health of the main devices must be checked in a cooking;

- if there are malfunctions in the work, you must immediately inform the master.

When performing work, it is important:

- use protective glasses, screens and shields;

- a special brush to remove an excess chips from the main nodes and parts;

- hands stop working cartridge unacceptable;

- on a working device, it is impossible to put parts, tools and other items;

- the speed box does not switch to the go;

- it is forbidden to work with faulty devices, as well as random devices.

After completion of work, it is necessary:

- immediately turn off the turning and screwing machine from the power grid;

- clear the main bonds from garbage and metal chips;

- butter lubricate all movable parts and the surface of the machine to protect it from corrosion;

- repair and repair of the machine is made after the authorization of the Master Master, subject to the rules of safe operation.

Absolutely any work on the processing of parts from the inside and outside are performed on a turning and screw machine, and today it can be bought in any online store. You only need to consult with the manager, pick up the machine and arrange your order. Delivery of the metalworking device will execute the store delivery service.